Feed Rate and Cutting Speed in Machining - feed rate equation

It will leave a less pale finish than a white Arkansas stone, but not as bright a finish as a diamond burr so it will dull down the diamond engraving to a slightly softer tone. Also used as a pre-polisher so can be followed with a grey rubber polisher for a very dark effect.

Whilst more expensive than coated burs, sintered will last far longer. Once you've mastered your technique you might like to splash out on some of these as they are a nice addition to your glass engraving tool kit.

These ball burrs start as small as 0.8mm which is ideal for lettering and very detailed work, and continue up in size to as large as 50mm, great for cold-working glass artists and sculptors.

For councils, schools and youth groups who are concerned about children using drills and electrical equipment, we recommend using a pin vice to hold the diamond burs in. These are very economical ways to draw on glass with a diamond burr. Pin Vices are also useful if you want to try stipple engraving or you wish to delicately mark the glass for something such as whiskers or hair. In this case, try a diamond scribing tool.

As with all diamond burrs, using them in the correct way will preserve the life of the drill bit so using them with water on a slow speed will prevent the burr from overheating and make them last longer.

Handengravingtools for metal

White Arkansas Polishing Stones are used for shading and smoothing and are much loved by glass engravers the world over. Start off with the following size and shape:

Here's a short introduction video from Lesley showing you how to use the different bits and burrs in your Lesley Pyke Glass Engraving Starter Kit. To view this on Youtube, CLICK HERE.

Or you could choose a set of 7 diamond ball burrs including one of each of these sizes: 0.8mm, 1.0mm, 1.5mm, 1.8mm, 2.0mm, 2.5mm, 3.0mm

Helpful note before buying a Dremel: If you would like to use a wide variety of burrs, polishers and stones to engrave with, do not purchase the Dremel 290 Hobby Engraver. This particular model is only compatible with two Dremel accessories, a carbide tip and a diamond tip.

To see a full list of our diamond burrs including shapes such as Cylinder, Wheel, Disc, Flame, Bullet, Cone and Lens please click here.

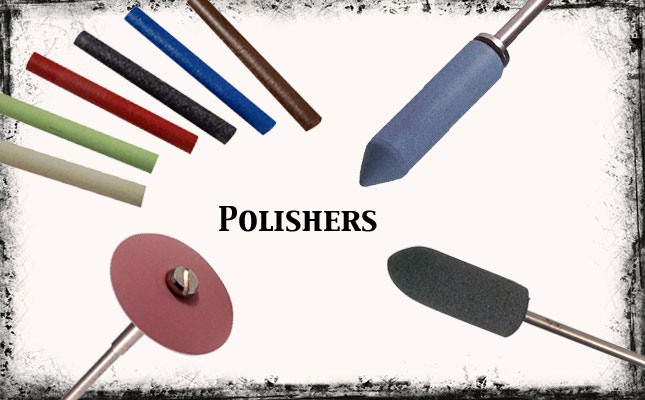

The Grey Rubber Silicone Polishers and Brown EVEFLEX polishers are great additions to your glass engraving supplies for smoothing and pre-polishing. We recommend the following popular shapes, to begin with:

Although soft and fine, these rubber burrs are still abrasives so be careful to stay within the lines of your design to avoid making any marks on the blank glass. Easier said than done sometimes I know!

The Guild of Glass Engravers - Network for glass engravers the world over. A super guild with some amazing talent from beginners to advanced.

If you're new to the wonderful world of glass engraving this short guide will provide you with a list of the small amount of kit you'll need to achieve something special. As you learn more and start to experiment with different techniques you can add different burrs, abrasives and polishers along the way.

Suffixusedwith way or sea

The following is a quick glance list to help you start engraving glass. Read on for more information about the purpose of each tool, optional extras and how to use your new glass engraving supplies.

Worldwide ISO9001:2015 Certified Stocking Supplier of Fasteners for ALL Industries, including Electronic Components, Certified Aerospace Hardware & CNC Custom Fasteners, Made-to-Print

Helpful Note: Sometimes you will find that you want to polish the top of an area without going into the cut you made with diamond burrs so that the top is dark but the cut is still white. This is done by using a hard polisher such as the grey or brown rubber polishers mentioned above to smooth out the top surface ("mountains") without going down into the cuts ("valleys"). If you want to do the reverse and just polish the valleys without touching the mountain tops then you can use a Mini Rubber Silicone polisher in knife edge or wheel shape to follow the path of the "valleys" without touching the surrounding "mountain tops".

Make sure to use our recommended taper mandrel with the bullet and cylinder shaped polishers otherwise, you may find the polisher flying off when you start your drill if the incorrect mandrel is used.

Tools forEngravingmetal

Alternatively, if you would like a beginners kit that is ready-made for you with all the bits you need, we have a few options:

Helpful Note: When you engrave glass using a drill you can get a very pronounced illusion of depth without actually cutting deeply into the glass. If you have engraved a house and you want it to look more real then you have to imagine the sun shining down on the house. Some parts of the house will be in full sunlight, some in full shade and some in partial shade. If you take an area of the house that wants to be in full shade but has been cut into with a diamond tool (and now looks bright white) all you have to do is polish the surface back with various rubber and silicone polishers until it is much darker. The polisher will smooth out the marks made by the diamonds without substantially changing the depth of their cuts. This is important as the cuts give visual clues as to the relative positions of the parts of the house.

These will give you the same effect as that of sandblasting. Tidy up any areas of sandblasting that may have been missed with this stone.

Coated or electroplated diamond burrs have a single layer of diamond grit meaning that once the grit has worn away or dulled you will need to replace the burr.

Sintered burrs have a much longer life span than coated diamond burrs due to being bonded with several layers of diamond grit instead of just one.

Much like the Arkansas stones these rubber burrs act as a pre-polisher to your work prior to using your silicone polishers (see below)

Note order placement does not guarantee stock fulfillment due to high demand. Large qtys or items showing limited stock, inquire 1st.

Along with the white Arkansas stone burrs and the silicone abrasive polishers, these are an essential piece of kit if you're looking to add texture and depth to your glass engraving. Again, look for 120 grit with a 2.35mm (3/32") shank. One small 3mm ball shaped one will be suitable to begin with and a flame one is always handy if your budget allows.

Also similar but more rigid and therefore harder wearing are the polishers from the EVEflex Technik range. These are available in cylinder and wheel shapes.

If you would like to take the plunge and start glass engraving we have a Bare Minimum Glass Engraving Kit for beginners, or if you would prefer you can join Lesley Pyke on her Patreon tutorial website and purchase a 'Lesley Pyke Glass Engraving Starter Kit'. The kits contain a small variety of the above-mentioned items so you can begin to engrave, add depth, shade and polish to your glass work.

Tool used in engravingcrossword clue

The ball shapes are most commonly used, but as your practice develops you might find you want to add a flame or a cone shape to your set of tools. The different effects and techniques you want to achieve will determine what shapes and sizes of burrs you will choose, and to begin with, it may be a bit of trial and error to see which ones you use the most and what your preferences are.

It goes without saying that when handling electrical equipment and glass you need to be careful. Please use these tips as a reminder:

Old term for a ribbon

Most rotary drills will take burrs that have up to a 2.35mm (3/32") or 3mm (1/8") shaft or shank (the end of the burr that pops into your drill) which is essential to know when you're looking for your carving burrs as anything larger than this will mean you will need an adapter or a drill that can take larger shank sizes.

There are burr lubricants available which promise to lengthen the life of your bits but we've not found one yet that does the job sufficiently. Water does just as well. You can always add one drop of washing-up liquid to the water if you wish - no suds though, please!

Taptite® and Plastite® are registered trademarks owned by REMINC (Research Engineering & Manufacturing Inc.) REMINC has not licensed the use of these trademarks to RC Fasteners & Components, Inc.

Using the Eveflex Brown Bullet Polisher provides the perfect subtle shading tool. Use after the Mini Rubber Silicone Bullet polishers in black (see below). The brown will give a slightly more subtle shading effect than the black. Alternatively, use after the grey rubber silicone polishers as mentioned above.

Professionaltool used in engraving

Lesley Pyke's Glass Engraving - Facebook page for beginners to learn techniques, share their work, ask questions and meet others. Furthermore, Lesley has some great Youtube videos that are very helpful.

The below image shows some fantastic glass engraving work done by Graham Smith using the Bare Minimum Glass Engraving kit.

Made from Silicon Carbide, these green stone burs are a must for your engraving work. Use them instead of diamond burrs on blank glass (the bits of glass you haven't engraved yet) or use them after the diamond burrs to fill in and add shading to your work.

Mini rubber silicone pin polishers are commonly used by glass engravers for smaller, more detailed work. These pin polishers are 3mm in diameter and fit into their own special mandrel. They come in different colours and each one relates to a different grade thereby giving your work a different effect.

If you're using a Dremel 3000 then a flexible shaft will also be a good investment at some point. With the flex shaft, you can hold the lightweight handpiece much like you would do a pen or an artist's brush.

Tool used in engravingDaily Themed Crossword

120 - 160# is a medium grit and is standard for coated burrs and ideal for your glass engraving endeavours. The higher the grit size, the finer the burr, so a 400# diamond burr will be finer and leave a smoother finish, but will remove less material than say a 120#.

Thread Forming Screws have a unique tri-lobular shape that forms a mating thread in an unthreaded pilot hole. The threads are work hardened as they are formed, providing a strong joint or assembly. The excess metal fills in behind the tri-lobular lobes to provide maximum contact and a secure assembly. The tri-lobular shape of the screw shank reduces friction during driving to assure low driving torque and also generates a prevailing torque that exceeds the level of a locking screw. The interference fit provides resistance to vibrational loosening.

Diamond ball burrs are your starter tool for engraving glass. These are sometimes referred to as diamond spheres or points and sometimes the spelling can be burrs or burs, depending on your preference or the country's spelling. Popular sizes, to begin with, are the following:

Tool used in engraving5 letters

When you first start out, try using a black mini rubber silicone polisher in a bullet or wheel shape. Black is the medium grade of these polishers and will set you off in the right direction. As you expand your knowledge and skills of your new craft you'll find you want a wider range of grades and shapes, they come in various shapes: knife edge, cylinder, wheel and bullet and various grades: coarse (white in colour), medium (black in colour), fine (blue in colour) and extra fine (pink in colour) these will be for your final polish and will help to add depth to your engravings. We recommend:

A handheld rotary tool such as a Dremel 3000 or something similar will do just fine, to begin with, and when you have the hang of it and more pennies in the piggy bank you can always treat yourself to a micro motor or a dentist's drill.

FG Burrs have a 1.6mm (1/16") shank so you'll need an adaptor to be able to use them in your rotary handpiece. These burrs come in a variety of shapes, sizes and grits. Popular burrs in this range are the Extra Fine Flame burrs, great for detail and fine work, and the ball burrs which are ideal for filling in large areas. Or why not try a mixed set of 6 with a few different shapes in?

A Dremel multi chuck will come in handy here too. These allow you to easily change burs and mounted points and will also allow you to use a wider variety of bits and bobs with varying sized shanks (this is the bit that goes into the drill, not the working end)

They must be cleaned with an aluminium oxide dressing stone before use, and again after each time you use them. By dressing them you reveal a fresh layer of diamonds each time, so they'll stay good as new for longer.

These Diamond Point Burrs will be good to have around if you want to do very fine line engraving such as hair, whiskers, fur or wispy tendrils. They're often referred to as Rats Tails and come in sizes such as 0.6mm, 0.8mm and 2.5mm.

The Grey polisher is coarser than the Brown. Also in the same series as the grey, are green and yellow rubber polishers - some additions to your tool kit for later on perhaps.

0086-813-8127573

0086-813-8127573