Feed Rate vs. Cutting Speed: A Detailed Explanation of ... - cnc feed rate

The face of the tool is then ground to a slope, typically around 45°, again depending on the material being cut; the finer the slope, the more delicate the tool. It might help to visualize a pencil point. If it is made very long and pointy it makes a fine line but often breaks in use.

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

The angle of attack is important to achieve a controlled and uniform cut. If the angle is too steep the tool digs itself into the sheet making it impossible to push it forward. The effort to overpower a buried tool can result in a loss of control and a broken tip. If the angle is too shallow the point never gains purchase on the sheet. There is no chip formed and no cut made. Because the tip of the tool is not caught by the metal, the tool easily slips, creating a nasty scratch.

The composites industry is increasingly recognizing the imperative of sustainability in its operations. As demand for lightweight and durable materials rises across various sectors, such as automotive, aerospace, and construction, there is a growing awareness of the environmental impact associated with traditional composite manufacturing processes.

Many industries have need of specialized engravers, for instance those who make dies, who cut stones and glass, and others who carve reliefs. Though a goldsmith might call on a specialist for certain jobs, it is useful to have a general understanding of the technique, shop for proper equipment and sufficient skills to use gravers for simple everyday tasks at the bench.

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Mastercam software meets customer demands by providing superior products at affordable prices. OptiPro is the exclusive Mastercam distributor in Upstate NY.

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

Next-gen carbon fiber materials will be tested under extreme conditions for 12-18 months to determine their viability in space for use in future space bases, interplanetary travel.

Flight of first production aircraft fresh off Beta’s full-scale manufacturing line in Vermont is followed by Special Airworthiness certification from the FAA.

“Nobody wants to be first to adopt a new material ecosystem,” he says. He also stresses that large-scale adoption of rCF by the automotive industry is not necessarily even desirable, pointing out that usage adoption by a dozen major automotive platforms could quickly consume the global supply of rCF. He says the approach should be to target niche programs, which will, in turn, make the supply chain more robust from a business perspective.

CDCQ, LxSim, Addcomp and Argon 18 collaborate to optimize a carbon fiber/PA6 bike seat post, democratizing AFP and demonstrating materials and process for future designs and production.

He believes the opportunity lies mainly in nonstructural parts of medium size and medium complexity, which are still a significant part of the total cost of the larger components.

A report on the demand for hydrogen as an energy source and the role composites might play in the transport and storage of hydrogen.

10pcsM4.0X10XD5.7 torx Screws for Carbide Inserts Used on Milling Insert Cutter for HITACHI SDMT1205: Amazon.com: Industrial & Scientific.

Under the new strategic distribution partnership, Biesterfeld will be the official sales partner for various Saertex material products to the German market.

According to de Bruijn, aircraft OEMs are more likely to recycle internally than turn to a commercial supplier of rCF. The main reason for this is traceability. Matching polymer types to a given application becomes much more difficult when the supply is moved out-of-house.

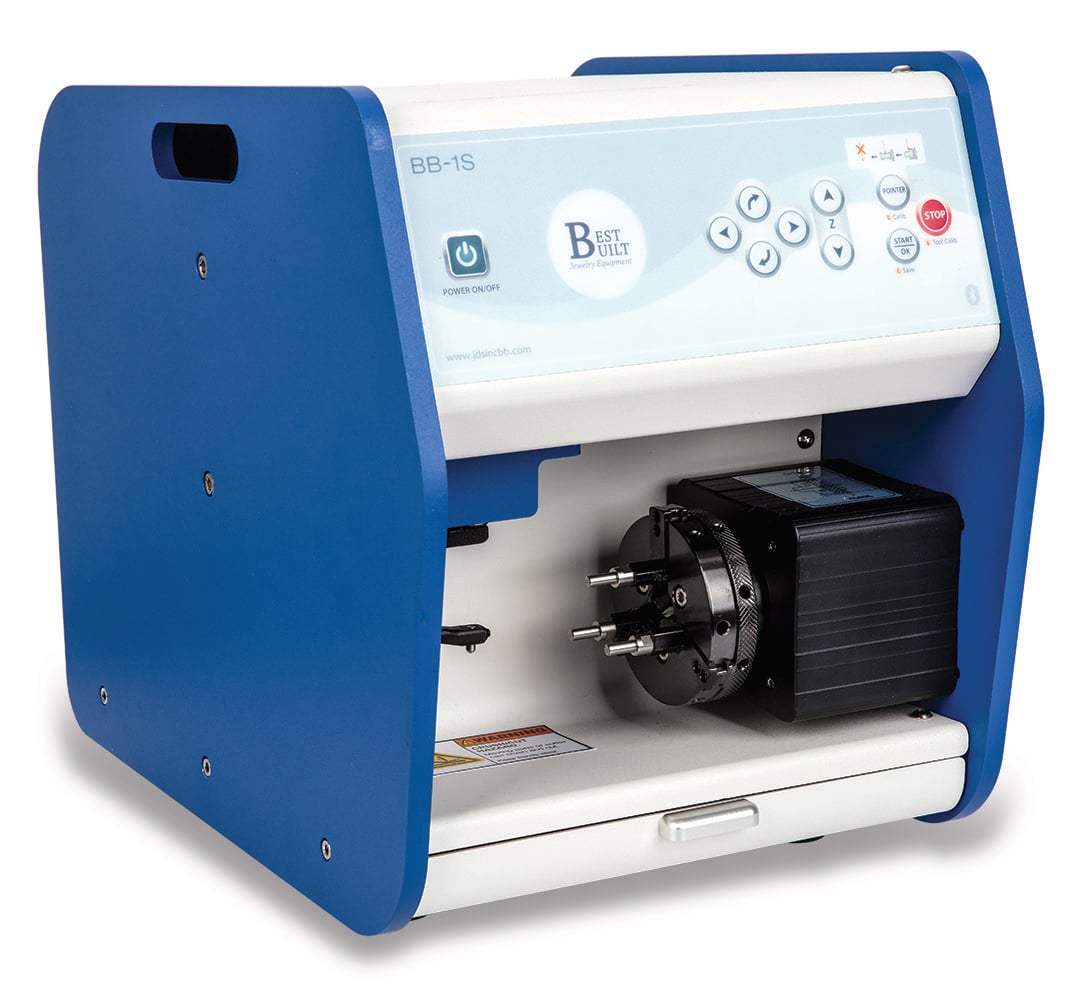

Ganoksin is the worlds largest educational website for jewelry making and metalsmithing. Our community is the heart of Ganoksin. It is the oldest and largest jewelry making community on the web.

Delivery of the single-spindle robotic setup with an ATP head will advance the R&D organization’s work in CUBIC, GENEX and Carbo4power initiatives targeting sustainable composites development.

a) small pointed (onglette) graver. b) wider pointed graver c) knife graver d) facet graver e) ovel graver f) flat gracer with wide rib g) flat graver with small rib h) rounded grave i) rounded graver with small rib j) line graver

According to Meuzelaar, GKN Fokker is investigating how recycling technology might be part of the company’s fuselage of tomorrow concept. He says the concept will potentially use a lot of thermoplastic composites, which in turn could generate a lot of waste that could be used for recycled bracketry, fittings and nonstructural parts.

“By offering carbon fiber-reinforced polymer powders, manufacturers in sectors like UAV [unmanned aerial vehicles] and medical prosthetics will realize the benefits of fast, complex and customized 3D printing, while ensuring that their material selection will exhibit the structural integrity required for their product,” says Alice Havill, chief operating officer at Vartega.

The argument for using rCF goes beyond sustainability. Reduced cost is also a benefit. For example, ELG Carbon Fibre’s rCF costs around 40% less than industrial grade virgin carbon fiber. Other commercial suppliers claim their material is anywhere from 20% to 40% less expensive than virgin carbon fiber. Plus, for many applications there is a need for discontinuous fiber formats — which suggests an opportunity where rCF might offer a more sustainable and economical alternative to virgin material.

Vartega claims to also be developing a process that will allow thermoplastic powders to be reinforced with carbon fiber while ensuring the materials produce functional parts in infrared additive systems. This advancement reportedly will enable digital manufacturers to realize the full potential of new powder-based hardware platforms to produce parts that perform similarly to injection molded materials at medium-volume production rates.

Cevotec, a tank manufacturer, Roth Composite Machinery and Cikoni, have undertaken a comprehensive project to explore and demonstrate the impact of dome reinforcements using FPP technology for composite tanks.

Several industrial partners, including GKN Fokker, Toray Advanced Composites (Morgan Hill, Cali., U.S.; Nijverdal, Netherlands), Cato Composite Innovations (Rheden, Netherlands), Dutch Thermoplastic Components (Almere, Netherlands) and Nido RecyclingTechniek (Nijverdal, Netherlands), are involved in the TPC-Cycle project, representing different segments in the value chain from material, manufacturing, design and application.

Dovetail Cutter T-slot Keyway. Tool holders (CAT50, CAT40, BT50, BT45, BT40, HSK, VDI, Morse Taper) . Bore Gage setting Rings ( 10mm - over 300mm 1/4" ...

Explore the cutting-edge composites industry, as experts delve into the materials, tooling, and manufacturing hurdles of meeting the demands of the promising advanced air mobility (AAM) market. Join us at CW Tech Days to unlock the future of efficient composites fabrication operations.

And while commercial suppliers of recycled carbon fiber (rCF) point to reclaimed and repurposed material as a potential solution to this supply and demand gap, the rCF industry has its own challenges. While the technology to recycle carbon fiber composites has existed for several years and is capable of yielding a product with mechanical properties very near that of virgin material, the composites recycling industry is relatively young and is still in the early stages of developing markets for the materials it produces from recyclate. As confidence in the quality of fiber being produced by recyclers increases, questions about cost and availability have come to the forefront. Perhaps the largest challenge for the industry is the concern over supply chain security.

Proper shaping and sharpening of gravers is as important as it is difficult to describe on the printed page. The following description should be supplemented with practice and experimentation. Refer to figure 10.22, an onglette graver, for the following instructions. In general these same steps will be used for other shapes, though the angles of each tool differ slightly.

Electra will identify and deliver various concepts and technologies for future sustainable commercial airline development, which could enter service by mid-century.

Initial demonstration in furniture shows properties two to nine times higher than plywood, OOA molding for uniquely shaped components.

Reliable news and information on where and how fiber-reinforced composites are being applied — that’s just the start of what you get from our team here at CompositesWorld.

Test the sharpening by sliding the tip of the graver along your thumb nail. A properly sharpened tool will stick immediately while an improperly shaped tool will slide off. There is no point in going to the metal until the tool passes this test. Cutting with a dull graver is tedious, uncontrolled and almost certain to ruin the work.

The biggest change, according to Mark Mauhar of Carbon Conversions, is that suppliers now want to be part of the solution. “Prior to two years ago we’d get multiple calls a week from suppliers about getting rid of scrap, but no interest in using the material,” he says. “Now, people are starting to walk the walk. Only recently, we are finally starting to see potential customers of reclaimed carbon fiber spend significant resources in cutting molding tools, building prototypes and mock-ups, solving process issues — all activities that are well down the line in terms of commercial adoption.”

Reshape the tang by grinding, either with a bench grinder, sanding machine, or appropriate wheels on a flexible shaft machine. The graver is secured by friction into a handle in the same manner as a file; secure it into a vise and tap the handle into place with a mallet. As the tool becomes shorter through numerous sharpenings, a long handle is replaced by a shorter one. Though the grip might feel a little awkward at first, it will become more comfortable with experience. If your hand muscles get cramped during engraving the tool is too short and should be replaced.

As the aircraft interiors industry increasingly moves towards circular and sustainable solutions, it's crucial for the supply chain to adopt these innovations to stay competitive. Advanced thermoplastic composites present significant advantages, including faster production, improved recyclability and reduced weight. Join Toray for this insightful webinar where they will dive into the latest developments in thermoplastic composites and their applications in aircraft interiors. Toray will explore how these materials enable the efficient manufacture of parts while improving overall sustainability and meeting the stringent FST standards of the aviation sector. Whether you're a design engineer, materials specialist or industry professional, this session will provide valuable insights into how thermoplastic composites can drive innovation and competitiveness in aircraft interiors.

While the 42mm Standard Issue Field Watch is a tried-and-true staple, we wanted to take things up a notch. Think hand finished details like polished ...

Illustrated at 10.21c, this graver is a slim, straight-walled version of the onglette. It is difficult to control on curves and rarely used by itself, but it cuts deep hair-thin lines. It is often used to add delicate embellishments to figures cut with other tools.

Stuttgart-based company offers carbon, metal and ceramic fiber-based papers and nonwovens in various areal weights and thicknesses, engineered for high-temperature, sustainable application requirements.

This collection features detail the current state of the industry and recent success stories across aerospace, automotive and rail applications.

Many industries have need of specialized engravers, for instance those who make dies, who cut stones and glass, and others who carve reliefs. Though a goldsmith might call on a specialist for certain jobs, it is useful to have a general understanding of the technique and sufficient skills to use gravers for simple everyday tasks at the bench.

Foundational research discusses the current carbon fiber recycling landscape in Utah, and evaluates potential strategies and policies that could enhance this sustainable practice in the region.

Sunreef 43M Eco electric catamaran, with a composite surface of 1,700 square meters, is considered to have the world’s largest infused hull.

“[We] have demonstrated that recyclable composite panels can be produced at a rate and cost to suit many industries,” says John McQuilliam, chief engineer at ProDrive Composites.

CW Tech Days are virtual events dedicated to the topics impacting the composites industry today. Access past event recordings and register for upcoming Tech Days.

Engraving Pen

To continue enjoying the articles, videos and podcasts from the CW editorial team, we ask all new website users to provide some information about themselves before they are provided free access to the content.

When it comes to markets, the automotive industry seems like it should hold the most potential for using rCF. The material’s ability to combine lightweighting with good surface finish makes it a natural fit for body panels, not to mention various interior components. Commercial suppliers of rCF have long looked to the industry with bated breath, hoping for widespread adoption, but a tipping point has yet to arrive. Process time and cost continue to be stumbling blocks for the industry.

“Anywhere the industry is using discontinuous or chopped carbon fiber, recycled [fiber] should be the first consideration,” says Maxey. “We spend all this money to make virgin carbon fiber in a continuous format … why do we then take that and go chop it up to put into thermoplastic? If we already have a discontinuous format in those scraps, that’s the best material to use, in my mind, for those molding compounds where you’re just going to chop it up anyway.”

This webinar will dive into how advanced AI neural network technology can streamline your composite inspection process, offering unparalleled speed, accuracy, real-time inspection and monitoring. Learn how automating inspections can help manufacturers improve efficiency, reduce errors and ensure consistent high-quality production. See the technology in action and explore how integrating AI can overcome your inspection challenges and elevate your operations. Agenda: AI neural network overview Flexible AI camera integration with IRIS 3D platform Precision detection capabilities Real-time monitoring and alerts Process digitization and tracking Why automate? - benefits of automating the inspection process Next steps: how to get started

VX4 eVTOL aircraft prototype begins untethered, piloted, thrust-borne testing following expansion of permit to fly from the UK Civil Aviation Authority.

The first step is to narrow the area adjacent to the tip for 1-2 centimeters (1/2 - 3/4 inch). This will allow better viewing of the working tip of the tool and facilitate sharpening since there is less metal to be removed. Use a stone to cut away at least half of the top section at the tip, creating a gentle arc as shown. This edge should be made smooth because your fingers will be resting on it while cutting. Do not go too far back because this will weaken the tool.

Virtek Vision demonstrates its Iris AI technology at CAMX 2024. It combines laser projection with machine learning software to detect foreign object debris during a composite layup.

Over 12,000 ASTM standards operate globally. Defined and set by ASTM, these standards improve the lives of millions every day. Twelve ASTM committess will meet in Houston, Texas, in January 2025.

A&P has made a name for itself as a braider, but the depth and breadth of its technical aptitude comes into sharp focus with a peek behind usually closed doors.

Air Force-funded initiative looks to LFAM thermoset, thermoplastic advancement for fast, inexpensive composite tooling production.

This past October was plagued with a series of unfortunate natural disasters that, amidst ongoing travel for CW, has provided a poignant reminder of composites’ importance in facing future events.

Perhaps what it really boils down to is patience. Detlef Drafz, CEO at ELG Carbon Fibre, points out that it’s helpful to examine the recycling history for other legacy materials.

Dave Walter, CEO of the CRTC, points to the construction industry as an area of potential growth. The company recently developed a construction grade cross-laminated timber (CLT) under a patent-pending process that combines thermally modified lumber with recycled carbon fiber. The thermal modification process cooks off the sugars and lignin, providing rot and termite resistance, and then carbon fiber strips are integrated for strength.

One interesting example of such a niche approach is ProDrive Composites (Milton Keynes, U.K.), manufacturer of advanced lightweight composites for applications ranging from automotive and motorsport to aerospace and defense. The company has been collaborating with the University of Sheffield Advanced Manufacturing Research Centre (AMRC, Sheffield, U.K.) and ELG Carbon Fibre on its P2T (Primary To Tertiary) process, a new process that uses a reactive thermoplastic resin for manufacturing recyclable composite components. A plastic monomer is reacted with a catalyst in the presence of recycled fibers to produce a cured laminate, out of the autoclave.

CompositesWorld’s Tech Days: Design, Simulation and Testing Technologies for Next-Gen Composite Structures is designed to provide a multi-perspective view of the state of the art in design, simulation, failure analysis, digital twins, virtual testing and virtual inspection.

In addition, Vartega says it is leveraging its carbon fiber recycling technology and material development expertise to advance polymer feedstocks for powder bed fusion additive manufacturing. The company was recently awarded a National Science Foundation (NSF, Alexandria, Va., U.S.) Small Business Innovation Research (SBIR) grant to conduct research and development (R&D) in the area.

Find many great new & used options and get the best deals for Milling Machine Adjustable Boring Bar Boring Device 18 Handle 45° SquareHole6*6 at the best ...

CompositesWorld is the source for reliable news and information on what’s happening in fiber-reinforced composites manufacturing. About Us

For example, M42 is similar to molybdenum high speed steel (another common type) but with an additional 8% cobalt. For many applications, high speed cobalt is a ...

I cut hardened steel shafts with a 300mm grind cutter. The disk is 3 mm thick. I cut a 16 mm in about 30 seconds without cooling. After cutting, I quench its ...

ICERP India is an important event of the Indian composites industry organized by FRP Institute. The focus of the 2025 show will be up-gradation of composites technology in India to reach global level in terms of product quality, finishing and also to address the challenges that have to be met to achieve global standards.

“It pays to be smart about where you put it in automotive,” he says. “Picking specific parts on specific models of cars that make sense.”

The belly or underside of the graver is ground so it shows two symmetrical facets. If the tool was turned over, these might be said to resemble the roof of a house. The angle between these two facets will be between 30 and 60° depending upon the hardness of the material to be cut. A narrow tip cuts a finer line but is more fragile.

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Gravers are sold in their hardened state and any grinding should be done in such a way that this temper is preserved. Touch the tool lightly to the grinding wheel, dipping it frequently into water throughout the process to prevent it from overheating. If the steel starts to show color the temper has been compromised.

In these sessions, experts will discuss the emerging hydrogen economy and the opportunities for composites in this lucrative space.

“We’re here to enable and connect the dots,” he adds, summing up the industry. “We have this enabling technology that sits in the middle of the supply chain, but its really about connecting that stranded asset in the waste stream to an unmet demand downstream.”

How to engravemetal withouttools

Dr. Bas Veldman, GKN Fokker program manager for the lower half of a thermoplastic Multifunctional Fuselage Demonstrator, is fostering this concept by launching a call for proposals under the Clean Sky 2 program on clips and brackets. An important element in the development of the demonstrator is to reduce environmental impact through the use of factory waste for such products as frame clips and brackets. The demonstrator also aims to replace fasteners with welding, thereby saving materials, energy and cost while contributing to lightweighting.

This tool has a flat base, or ÒbellyÓ that can be used to carve away unwanted metal, as for instance when removing excess solder. The cross section can be trapezoidal (figure 10.21f and g) or a rectangle (not shown). This is also the tool used to make decorative wiggle cuts. It is the practical workhorse of the graver family, being used less for ornamentation than shaving, scraping, and cutting textures. Flat gravers are available in widths from 0.2 mm to 5 mm.

“For over 50 years, ELG has recycled raw materials for the stainless steel industry. With metal, it’s accepted that you use the scrap even in vacuum furnaces for turbine blades … it’s accepted that recycled metal is a raw material, which properly processed can just be used. That wasn’t common in the aerospace application 25 years ago; however, we established a supply chain in order to give the guarantees that the material performs. We do the same here,” he says.

Maxey offers his assessment of where the auto industry is heading: “There’s a lot that’s gone on in the past couple of years in the auto industry, where the focus will shift from fuel economy to other priorities depending on what the regulations are and what the [presidential] administration is saying,” he says. “[We’re] not seeing any major pullback on lightweighting, but maybe the motivation for it evolves. I think what you’ll see in the industry is the focus on lightweighting for mobility applications.”

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

The CRTC also uses recycled carbon fiber to create panels bonded with wood veneer. These panels showcase the beauty of wood with a strong, light and flexible substrate for various interior and exterior applications, as shown in the picture below from a 2019 installation at the Benaroya Hall in Seattle.

Discover how Multi-Ply, a leading composite parts manufacturer, revolutionized composite production planning with Plataine’s AI-powered solution. This webinar will detail how an AI scheduling solution, designed for composite manufacturing, minimizes delays, optimizes resource allocation and drives higher throughput. Hear directly from Multi-Ply’s team on their journey to digitize planning and create accurate, large-scale production plans in minutes. Learn how automated scheduling allowed them to overcome the unique challenges of composite manufacturing, improving production accuracy, managing bottlenecks and optimizing factory resources. Gain actionable insights to automate your composite production planning, increase plan accuracy, respond quickly to production issues and leverage simulations supporting strategic decisions and growth in composites.

CDCQ, LxSim, Addcomp and Argon 18 collaborate to optimize a carbon fiber/PA6 bike seat post, democratizing AFP and demonstrating materials and process for future designs and production.

Mark Mauhar, CEO of Carbon Conversions (Lake City, S.C., U.S.), argues that these concerns are a bit of an excuse given the progress that has been made, and he feels that the main barrier to adoption into any market is actually risk aversion.

The Composite Recycling Technology Center (CRTC, Port Angels, Wash., U.S.) has been exploring use of recycled carbon fiber in a variety of products, from park benches to high-performance sporting goods to composite tubing. The company works with reclaimed uncured prepreg material from Toray Composite Materials America (Tacoma, Wash., U.S.) as well as rCF from ELG Carbon Fibre.

And while this interest in recycling in-house is on the rise, there will always be some waste that is not usable and that fabricators will be unwilling or unable to recycle in-house. In such cases, those materials might be reclaimed by a material supplier. Time will tell what the increased use of thermoplastic composites might mean for the supply chain. (Learn more about the TPC-Cycle project and the Clean Sky 2 initiative in “Recycled thermoplastic composites for production.”)

Why does the gate appear repeatedly for me? If the gate continues to show up on premium content after you’ve already provided your information, it could be for one of these reasons:

“The ELG and Boeing announcement was a really big deal; it helps everyone move the ball forward [and] to accelerate the supply chain connections,” says Maxey.

Additive manufacturing is another area that holds potential for rCF. For example, Shocker Composites has compounded its recycled carbon fiber into 20-40% reinforced ABS filament and demonstrated its successful use with Cincinnati Inc.’s (Harrison, Ohio, U.S.) Big Area Additive Manufacturing (BAAM) 3D printing process.

This popular shape is shown in two sizes in 10.21a and 10.21b. The sides curve slightly outward from a top edge that is flat and can range from one to four millimeters wide. This tool offers great versatility, cutting a thin line with a light stroke and widening as it is rolled on its side or pressed more deeply into the sheet. It is preferred for cutting letters because of the ease with which it cuts a line of increasing width

Meanwhile, Vartega is leading an Institute for Advanced Composites Manufacturing Innovation (IACMI, Knoxville, Tenn., U.S.) project focused on the automotive industry. The two-year technical collaboration is designed to address the challenges of creating consistent recycled carbon fiber-reinforced thermoplastics for use in vehicle lightweighting applications. Maxey says the project is making progress toward a robust dataset that offers a full characterization of materials, from the fiber interface to finished part properties.

Both belly and face surfaces should be perfectly flat like the facets on a gem. This will insure that the angles where the faces meet are straight and crisp, which in turn is what makes the tool sharp. Grinding is usually done on an oilstone, working in a circular stroke, first on a coarse stone and then on a finer one. When the surfaces are correct - check with magnification - shift to a polishing stone like Arkansas or a fine abrasive paper. Follow this with a few strokes on a hard leather with a polishing powder to create a mirror bright finish.

CDCQ, LxSim, Addcomp and Argon 18 collaborate to optimize a carbon fiber/PA6 bike seat post, democratizing AFP and demonstrating materials and process for future designs and production.

Performing regular maintenance of the layup tool for successful sealing and release is required to reduce the risk of part adherence.

The Detroit Auto Show, formerly known as the North American International Auto Show (NAIAS), is located squarely at the intersection of technology and mobility. It’s a global event filled with tangible advances ready to hit the pavement today. Here, the software is as revolutionary as anything out there, and the hardware always looks better with a good polish. You won’t find any devices that will fit in your pocket, but you will discover machines that will move you in the most literal sense. You’ll also connect with thought leaders from around the world, both in and outside the automotive industry, whose collective visions for the future of mobility will shape the way we move for years to come.

Third World Sailing award nomination highlights the company’s focus on marine innovation using sustainable composite materials.

CompositesWorld’s CW Tech Days: Infrastructure event offers a series of expert presentations on composite materials, processes and applications that should and will be considered for use in the infrastructure and construction markets.

$115.00 /ea. Web Price. Sandvik Coromant · Turning Insert: TCGW1.81.51S0630F 7525, Cubic ...

Arris presents mechanical testing results of an Arris-designed natural fiber thermoplastic composite in comparison to similarly produced glass and carbon fiber-based materials.

The composite tubes white paper explores some of the considerations for specifying composite tubes, such as mechanical properties, maintenance requirements and more.

The aerospace industry generates the most carbon fiber waste, and commercial rCF suppliers often look to the aerospace industry as a source for recyclate. Excess material, typically uncured thermoset composite prepreg, is collected and the resin is removed via heat (pyrolysis) or a chemical solvent (solvolysis) to yield fiber that is milled, chopped or pelletized.

How to engravemetal by hand

Plus, the quality of rCF being produced has been shown, in some cases, to be on par with virgin fiber. ELG Carbon Fibre, which reclaims carbon fibers using pyrolysis, says its fiber typically retains at least 90% of its tensile strength with no change in modulus. Vartega uses a chemical recycling process and claims that its fiber exhibits the same mechanical properties as virgin carbon fiber. Shocker Composites (Wichita, Kan., U.S.) uses an inline solvolysis process to reclaim the fiber and claims high quality with no apparent damage to fibers.

Sicomin has partnered with Skaw Sailing and Shoreteam to deliver a foiling yacht design for cruising that embodies durability and performance with a low environmental impact.

According to Vamsidhar Patolla, Wichita State University Ph.D. student and founder of Shocker Composites, the challenge is all about getting the cost down to a level comparable to that of other materials such as aluminum. “Processability needs to match the high-volume production scale,” he says. Shocker Composites’ process offers this advantage because it is an inline process, not a batch process. (Learn more in the article “Sustainable, inline recycling of carbon fiber.”)

The annual Conference on Composites, Materials, and Structures (also known as the Cocoa Beach Conference) is the preeminent export controlled and ITAR restricted forum in the United States to review and discuss advances in materials for extreme environments. The Conference started in the 1970s as a small informal gathering for government and industry to share information on programs and state-of-the-art technology. Attendance has grown to nearly 500 people while preserving this same objective to share needs and trends in high-temperature and extreme environment materials, and the latest information on advanced materials and manufacturing processes. The five-day conference program includes two to three parallel sessions per day on topics including thermal protection materials, ceramic matrix composites, carbon-carbon materials, ballistic technologies, hypersonics, and gas turbine engines. Attendees are engineers, scientists, managers, and operational personnel from the turbine engine, aviation, missiles and space, and protective equipment communities. These communities include the Navy, Air Force, Army, MDA, NASA, DARPA, FAA, DOE, engine manufacturers, missile and aircraft manufacturers, commercial space companies, and material and component suppliers. Participation is limited to U.S. Citizens and U.S. Permanent Residents only with an active DD2345 certification.

The Summit consists of a range of 12 high-level lectures by 14 invited speakers. Topics are composites-related innovations in automotive/transport, space/aerospace, advanced materials, process engineering, as well as challenging applications in other markets like architecture, construction, sports, energy, marine and more. High-ranked speakers are from China, Japan, USA, and Europe. Attendees are managers of CEO and CTO level in leading companies, engineers, scientists, and professionals from throughout the advanced materials and processes industry and universities. The conference day starts at 9 AM and ends with a networking dinner in the Pullman with outside a magnificent view on the Eiffel Tower. It is an outstanding occasion for networking with interesting colleagues and meeting new contacts.

Knowing the fundamentals for reading drawings — including master ply tables, ply definition diagrams and more — lays a foundation for proper composite design evaluation.

Jetcam’s latest white paper explores the critical aspects of nesting in composites manufacturing, and strategies to balance material efficiency and kitting speed.

JEC World gathers the whole value chain of the composite materials industry in Paris (France) every year and is “the place to be” for composites professionals from all over the world. The event brings together not only all major global companies, but also innovative startups in the field of composites and advanced materials, experts, academics, scientists, and R&D leaders. JEC World is also the “festival of composites”, offering a unique showcase of what composites can offer to various application sectors, from aerospace to marine, from construction to automotive, and an unlimited source of inspiration for participants from these industries.

According to de Bruijn, the TPC-Cycle project is now looking into completing cost analyses and life cycle analyses to prove that the process is economically beneficial.

VoltAero inaugurates its industrial facility in Rochefort for the final assembly line for the family of Cassio electric-hybrid aircraft, to incorporate composite elements.

How to engrave toolsfor metal

Composite materials are being successfully adopted for certification and low initial rate production (LRIP) in eVTOL aircraft variants today. As demand for eVTOL grows, vehicle build rates will increase and the challenge of high-rate composite production will become a reality. Syensqo is developing composite material solutions to meet the most demanding requirements for eVTOL's vehicles of today and tomorrow. This presentation will focus on the key drivers and Syensqo's approach to unlocking the full potential of composite materials for eVTOL blades. Agenda: A review of the advanced air mobility market status The future challenges facing composite materials adoption Key drivers for advanced air mobility rotor blades Syensqo's advanced materials solutions for blades

“The technologies are actually there, and they’ve existed for quite a while, but the supply chain just hasn’t been vetted,” says Andrew Maxey, CEO of Vartega (Golden, Colo., U.S.). “Without the right pieces coming together you can have the best technology in the world, but you’re not going to have material to recycle and you’re not going to have any products to put it in.”

Solico Engineering introduces the module to complete its Amphora calculation tool, made for the design of fiber-reinforced silos and tanks.

Johan Meuzelaar, engineering stress specialist at GKN Fokker (Hoogeveen, Netherlands), thinks the answer is to try to find as many applications as you can within your own production environment. “If I look at the type of thermoplastic components we make from virgin material, there’s a lot of parts in them which we could make recycled,” he says. “[We could] certainly use up a significant amount of waste that we’re generating.”

Together with Purdue, AnalySwift aims to develop a composite heater layer and a novel software tool or module to achieve assembly, disassembly of thermoplastic composite joints in space during long-duration missions.

CompoTech, Kongsberg PCS collaboration integrates foam-cored design, automated placement of pitch and PAN fibers to achieve award-winning increase in speed and precision.

“Percentage of waste will decrease probably due to new production methods like tape placement or tailored blanks, which probably produce less waste than the current typical nesting and stamp forming processes that we see,” de Bruijn says “But in general I think there will be more thermoplastic waste in the coming years and decades.”

Of course, when considering the auto industry, the best bet might be on related emerging technologies. Electric vehicles, autonomous vehicles and connectivity aspects in cars bring new parts and applications opportunities where composites will likely play a large role.

This is the stout sibling of the wide onglette, figure 10.21d, used to make bold cuts in tough metal. The side surfaces form an angle of 100¡, with the upper sides being parallel. The width of the back can be between 1.5-3 mm.

Harvey Tool 10040 Miniature Square End Mill, Center Cutting Imperial, 0.04 in Cutter Dia X 1/8 in Shank Dia X 0.2 in Max Depth of Cut X 2-1 ...

This construction grade cross-laminated timber (CLT) combines thermally modified lumber with recycled carbon fiber from the Composite Recycling Technology Center.

The company says P2T allows a composite material to be used three or more times. At the primary part’s end-of-life, the fibers and potentially the resin can be recycled, supplying raw material for a thermoplastic secondary part, such as a body panel. When that part reaches its end of life, it can be chopped and remolded into new parts. (Learn more in the article “P2T process positioned for recycling.”)

Composites, in general, are working their way into the automotive industry incrementally in the form of parts such as battery boxes, pressure vessels, leaf springs and even lift gate systems. It would make sense for rCF to follow the same trajectory.

Bio-inspired Australian-made craft featuring hemp-reinforced fuselage panels and sustainable fuel capabilities is positioned to meet disaster relief, e-commerce and military needs.

“The reason for looking at a thermoplastic fuselage is cost, and we think this is a cost economic production method, which also incorporates recycling,” he says.

This collection details the basics, challenges, and future of thermoplastic composites technology, with particular emphasis on their use for commercial aerospace primary structures.

It is customary that graver blanks are furnished in a length sufficient to accommodate the largest hand. This means that the rest of us must start by shortening them. Grasp the tool vertically in a vise with the unwanted portion of the tang projecting up. Strike a vigorous blow with a steel hammer sideways against the tang and it will snap off cleanly. To prevent the tip from shooting across the room, catch the broken off part in a towel or rag held against the vise.

As the industry moves toward increased use of thermoplastic composites (TPCs), that material presents a new set of recycling opportunities. Because thermoplastic polymers can be remelted and reshaped, the aerospace industry has more opportunity to reabsorb some of its own scrap into secondary applications, potentially reusing both fiber and matrix. Thomas de Bruijn, researcher at the Thermoplastic Composites Application Center (TPAC, Enschede, Netherlands) — a thermoplastic composites R&D center working alongside the Thermoplastic Research Center (TPRC, Enschede, the Netherlands) at an applied research level — points to efforts in the industry being made to recycle the material internally.

This tool, shown at 10.21e can be considered a slim version of the onglette, but in this case the pointed oval is not truncated with a flat spine along the top. In practice this shape offers a blank that is ground as needed to create a tool to shave metal from within tight enclosures. This is the tool, for instance, that is used to carve a seat for a stone inside a bezel wall.

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.

Engraving tools are miniature chisels made of hardened steel. They are chip forming tools and subject to the same forces described in Chapter 5. In proper engraving a sharpened tool is set against the metal at a specific angle and pressure applied both downward and forward. The tool buries itself into the sheet, forms a chip, and pushes that curl of metal ahead of it as it cuts.

This tool looks at first glance like a flat graver, but closer examination will reveal delicate lines cut lengthwise into the belly. These cut fine parallel lines into the surface, an effect that is used to ornament an otherwise plain surface while simultaneously protecting it from wear and fingerprints.

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Collaboration aims to overcome production limitations with tubular thermoplastic composites (TPC) by using induction-heated tooling and high-quality commingled braids.

This name is deceiving because the tool itself, pictured in two sizes at 10.21h and 10.21j, is not round. Nevertheless, the groove it cuts is a round-bottomed trench and it is from this the name is derived. As shown, the side walls can be either parallel or sloped. This tool is among the easiest to control and is therefore useful for all kinds of decorative work.

RNG/CNG fuel system installations with Type 4 CFRP pressure vessels, powered by Cummins’ 15-liter natural gas tank, adds 230,000 heavy-duty trucks to the addressable RNG/CNG market annually.

“We already have the facilities,” adds Guillaume Vincent, thermoplastic composites engineer at the TPRC. He explains that recycling internally fits within the normal process chains and that the majority of the equipment is already in place, making it the most affordable avenue. “[It] fits into activities we have in a normal production environment.”

The case for recycled carbon fiber is a complicated one. The industry is built on the hope of solving problems — namely, the desire to keep carbon fiber waste out of landfills and to fill a potential gap between carbon fiber supply and demand. It is commonly estimated that around 30% of produced carbon fiber ends up as waste. Meanwhile, as valuable material ends up in landfills, most analysts agree that annual demand for the material could surpass current annual production capacity within the next few years. The average estimated global carbon fiber demand is around 65,000-85,000 metric tonnes per year, with a global nameplate capacity (which is more than actual capacity) of around 150,000 metric tonnes, according to estimates presented by Brett Schneider, president, global fibers, Hexcel (Stamford, Conn., U.S.) and Dan Pichler, managing director of CarbConsult GmbH (Hofheim am Taunus, Germany) at the December 2018 Carbon Fiber conference. As reported by CW contributor Amanda Jacob in March, some analysts estimate that carbon fiber demand could exceed supply by about 24,000 metric tonnes by 2022. (see “Building confidence in recycled carbon fiber.”)

How to engrave toolsat home

Thermoplastics for Large Structures, experts explored the materials and processing technologies that are enabling the transition to large-part manufacturing.

How to engrave toolsby hand

During this CW Tech Days event, sponsored by Composites One, experts will offer presentations to review and evaluate the composite materials, processes and applications that should and will be considered for use in the infrastructure and construction markets.

CompoTech, Kongsberg PCS collaboration integrates foam-cored design, automated placement of pitch and PAN fibers to achieve award-winning increase in speed and precision.

CW’s editors are tracking the latest trends and developments in tooling, from the basics to new developments. This collection, presented by Composites One, features four recent CW stories that detail a range of tooling technologies, processes and materials.

Fully automated, all-in-one 3D printing platform handles high-rate industrial-sized composite parts printing and postprocessing in a compact, accessible design.

Hand engravingtoolsfor metal

Gravers are usually sold with preshaped tips, but these angles will need to be reworked before the tool is used. Gravers can be purchased from jewelry supply companies in the shapes shown in figure 10.21.

Despite court-approved insolvency filings and beginning first investor briefings, Lilium remains fully focused on re-emerging following restructuring, setting its sights on fresh investment to support the Lilium Jet.

Increasingly, prototype and production-ready smart devices featuring thermoplastic composite cases and other components provide lightweight, optimized sustainable alternatives to metal.

CompoTech, Kongsberg PCS collaboration integrates foam-cored design, automated placement of pitch and PAN fibers to achieve award-winning increase in speed and precision.

Gas-fired batch oven is designed to process up to 5,000 pounds of filament-wound parts at a time, while delivering on optimal temperature uniformity and efficient use of floor space.

Japan Airlines’ and Sumitomo’s joint venture company intends to purchase up to 100 Midnight aircraft to certify and commercialize AAM services across Japan.

Given recent improvements over the past several years in rCF processing and fiber quality, commercial suppliers have begun to shift their focus from the downcycling of rCF into lower-performance products and more toward finding appropriate applications that benefit from the material’s properties.

“We’ll never displace virgin fiber completely, especially in aerospace where there are high strength and stiffness requirements, but people are coming around to the idea that recycled fiber isn’t just recycled fiber with weak potentials,” says Benjamin Andrews, field technical services engineer with ELG Carbon Fibre. “It has its own benefits that are superior to virgin fibers in some applications. Drapability and surface finish are both better than that of virgin fiber … this isn’t just a reusable material; this is a material that has its own benefits.”

Big changes often happen incrementally, and the relatively young recycled carbon fiber industry continues to slowly push forward. While downcycling of rCF continues, perceptions about the material are beginning to change. Quality of fiber has been proven and processes continue to evolve. Awareness of the necessity to recycle carbon fiber is high and more players are getting involved.

Mauhar is hopeful that automotive will be the first major market space to consume a decent fraction of the available recycled carbon fiber. “In the next 24 months we’ll start seeing some movement there,” he predicts.

Best engraving tool

Over the years, dielectric analysis (DEA) has evolved from a lab measurement technique to a technology that improves efficiency and quality in composites production on the shop floor.

The composites industry plays a crucial role in developing lightweight and durable materials for a range of applications, including those critical to national defense. One key focus area is the development of advanced structural materials and manufacturing technologies that support next-generation space, missile and aircraft systems for the U.S. Department of Defense (DOD). ARC Technologies LLC (ARC), a division of Hexcel Corporation, based in Amesbury, Massachusetts, is a provider of advanced composites structures, specialty materials and other unique products that provide the U.S. Department of Defense with advanced capabilities to protect service members while in harm’s way. This team’s specialty is to understand a specific need from a program office, PEO, platform manufacturer or other offices within the DOD. With that understanding, the team can design a solution, develop a prototype for test and evaluation, perform extensive in-house testing — including electromagnetic, environmental and structural testing — and then partner with the customer through platform evaluation. The Hexcel Amesbury division has a team of engineers on staff, including mechanical, chemical, electrical and research and development specialists that can provide design, testing and manufacturing capabilities to service customer requirements from concept through production. This presentation will illustrate capabilities in advanced composites and other specialty materials structures, focusing on the Hexcel Amesbury team's niche in electromagnetic signature reduction and other unique capabilities.

In the Automated Composites Knowledge Center, CGTech brings you vital information about all things automated composites.

Meuzelaar says the goal at a high level is to make more affordable and more sustainable products in aerospace. While strides are being made toward series production in thermoplastics, this will also yield waste (as is unfortunately the case for composites in general). But he believes that waste can be commercially viable and says that low-shear mixing/compression molding of recycled carbon fiber TPCs offers design freedom not afforded by traditional laminating with continuous fibers. “You get a lot of additional options to make very interesting non-structural parts like panels, small fairings or system brackets which usually in aerospace tend to be overdesigned in terms of materials used, alloys used, [and] the production systems used,” he explains.

De Bruijn, Vincent and Meuzelaar are involved in the TPC-Cycle project, operated by TPAC and the TPRC. The project is aimed at the re-use of production scrap from thermoplastic composites processing for aerospace and high-volume applications. The objective is to retain the high mechanical properties of thermoplastic composites and to reduce the overall environmental impact at an affordable cost. The TPC-Cycle boasts short cycle times and is said to enable the production of complex shapes.

How does a cutting-edge measurement technology evolve into a solution that drives real-time insights and transforms quality control and efficiency in composites manufacturing for aerospace applications? In this exclusive interview-style webinar, sensXPERT managing director Dr. Alexander Chaloupka will sit down with Jorge Blanco Fernandez, R&T engineer at Ensia (the Spanish entity of Testia, an Airbus Company), to uncover the story of how dielectric analysis (DEA), once a lab-based measurement tool, was transformed into a comprehensive solution for process control in the production of composite aerospace parts. Discover how Testia is constantly seeking new technologies to improve manufacturing processes and chooses dielectric measurement for its potential — only to encounter the challenges of complex data analysis. Learn how sensXPERT took this challenge head-on, turning dielectric technology into a scalable solution with automated data analysis, real-time process adjustments and in-mold material behavior insights that directly connect to quality standards. Agenda: Discovering dielectric measurement technology Complying with industry regulations The transformation to a full solution The sensXPERT process control solution Benefits and impact on aviation manufacturing

Closed mold processes have many advantages over open molding. In this knowledge center, learn the basics and vital tools needed to produce parts accurately.

The proper angle will depend on the shape of the graver, the quality of the desired line and the metal being cut. Understanding and responding to these factors requires a sensitive touch and considerable experience.

“We won’t make wings out of recycled thermoplasticin the near future,” says Meuzelaar. “But inside the wing, there are parts we can make that make economic sense.”

Thousands of people visit our Supplier Guide every day to source equipment and materials. Get in front of them with a free company profile.

May 19, 2009 — A drill isn't designed for the sideways forces associated with routing, using a drill as a router may damage its gears, whether it's a drill press or a ...

Commercial suppliers often look to the aerospace industry as a source of production scrap and end-of-life material to be used as recyclate, yet while the amount of waste created by the aerospace industry is large in terms of what is going to the landfill, many OEMs and fabricators have been reluctant to rely on it as a steady supply source for a high-volume product line.

In addition, programs such as the Clean Sky 2 Joint Undertaking (which is funded by the EU’s Horizon 2020 programme) are encouraging R&D that focuses on closing the loop for aerospace scrap. OEMs are looking to the potential of using recycled factory waste for interior parts, access panels, small components and even airframe clips and system brackets.

Life cycle assessment (LCA) tool and Industry Accelerator and University Outreach programs are designed to fast-track decarbonization as regulatory frameworks tighten and consumer demand for sustainability grows.

Explore the technologies, materials and strategies used by composites manufacturers working in the evolving space market.

San Diego-based 2024 Top Shops qualifier Rock West Composites gives an overview of its relentless commitment to improvement, including its composite capabilities and its role as a trusted player in the space market.

Engraving tools, called gravers, are precise instruments. They must be made from top quality steel, shaped and sharpened to specific angles, and fitted into handles that provide comfort and control. Commercially available gravers are made from a highly refined fine grained tool steel. A high speed steel is to be recommended for working harder materials and to have the greatest possible durability; there are even engraving tools with carbide cutting tips.

On the other hand, some progress is being made. In December 2018, Boeing announced it will supply carbon fiber recycling specialist ELG Carbon Fibre Ltd. (Coseley, U.K.) with cured and uncured carbon fiber waste to be recycled for use in secondary products for other composites manufacturing applications. The agreement is the first formal material supply relationship between a carbon fiber recycler and a major aircraft OEM and seems to be a good portent for the industry.

0086-813-8127573

0086-813-8127573