Feed Speeds. - tapping speeds and feeds calculator

Companies around the world use CNC machining to craft high-quality components from diverse materials like ceramics, wood, and composites. Metal and plastic take the forefront in mass production, with metals enjoying wider machinability. Machinists can adeptly tackle...

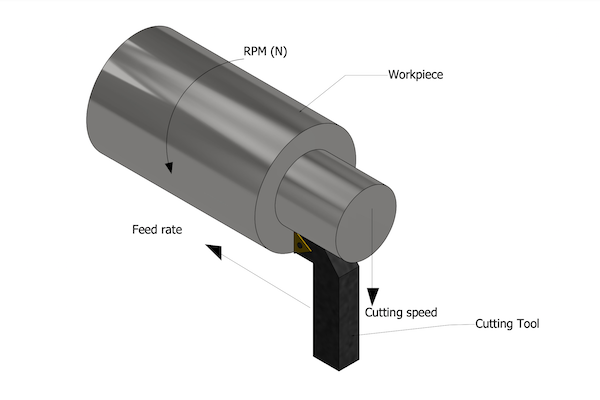

Cutting speed can be compared to the linear velocity of the car, which depends on the wheels’ diameter and RPM. It measures the linear distance moved by the cutting tool against the machined part at a given time. Cutting speed is measured in millimeters per minute (mm/min), meters per minute (m/min), or feet per minute (ft/min).

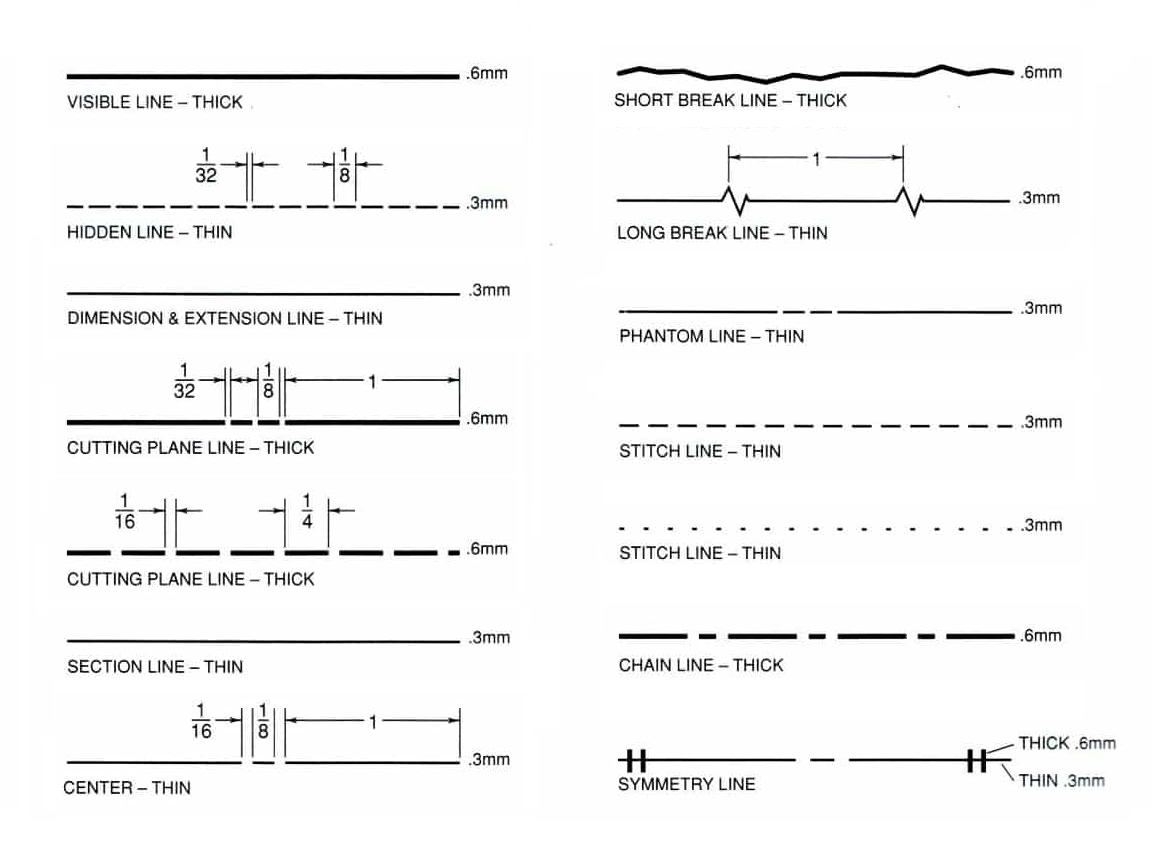

For all views of one piece or assembly to the same scale, the thickness of the lines should be the same. Medium and extra-thick lines should be used only in special cases.

angle · hole. Strong matches. cavity · compartment · cranny · hideaway · indentation ... Browse related words to learn more about word associations. alcove. noun ...

But what is cutting speed, and how does it differ from feed rate? And how do these machining parameters contribute to the success of your manufacturing project? This article answers all of these questions and more.

Apr 11, 2023 — It's essential to understand the various types of drill bits available and their unique features, including materials, coatings, point angles, and lengths.

The height of the keyseat itself is not dimensioned because, once the top of the shaft is cut away, there is no feature left to measure.

Feed rates also affect the tool life and power consumption during machining, but their effects are usually negligible compared to cutting force. Instead, feed rates are more likely to affect the machining time and surface finish of the machined part.

Cnc cutting speedcalculator

Each line should have one of the two thicknesses, thick or thin, and the ratio of the thicknesses must be not less than 2:1. In many textbooks (especially, of the US authors) you will come across the thicknesses of lines: 0.3 mm and 0.6 mm. In general cases it is good enough in practical work.

Cnc cutting speedformula

The alphabet of lines is a set of standard line types established by the American National Standards Institute (ANSI) for technical drawing. The alphabet of lines and the approximate dimensions used to create different line types, are referred to as linestyles when used with CAD.

In Graphics Communication practice there is the whole collection of different lines, which are used for drawing purposes.

Extension lines should not cross dimension lines, and they should avoid crossing other extension lines whenever possible. When extension lines cross object lines or other extension lines, they should not be broken. When extension lines cross or are close to arrowheads, they should be broken for the arrowhead.

In contrast, we can compare the feed rate to the wheels’ rotation in the car analogy. Feed rate is simply the distance the tool travels during one revolution of the part. We measure it in inch per revolution (inch/rev) or millimeter per revolution (mm/rev).

Cnc cutting speedchart

CNC milling is a CNC process that involves the use of rotating cutters to remove portions of a block of material (or workpiece) till the desired custom shape (or feature) is made. It allows manufacturers to create intricate parts accurately while meeting tight...

Gensun Precision is a leading provider of CNC machining services across Asia. Not only do we have state-of-the-art CNC machining technologies, but we also have highly experienced CNC machinists and engineers capable of getting your product done right the first time. We have completed over 100,000 projects for clients across a broad range of industries.

Normally, gear drawings include a table of information, called cutting data, for manufacturing. A detail drawing of a gear would also include other dimensions not found in the table (root diameter, bore diameter, keyway dimensions).

Cutting speedformula

To help you understand these two terms, let’s consider a simple analogy of a car moving at a linear speed of 60 km/hr with wheels rotating at 500 rpm. You’d agree that the wheels’ diameter and rotation are responsible for the car’s movement along a paved road. But when describing the vehicle’s speed to a friend, you’d explain it in terms of kilometers per hour.

As a rule, the harder the workpiece material, the slower the cutting speed you should implement during machining. For example, materials like titanium will require a lower cutting speed compared to steel.

In cases where other than shown types of lines are used for special drawings (for example, electrical drawings, pipeline diagrams, or building drawings) the conventions adopted must be clearly indicated by reference to specific standards or by notes on the drawings.

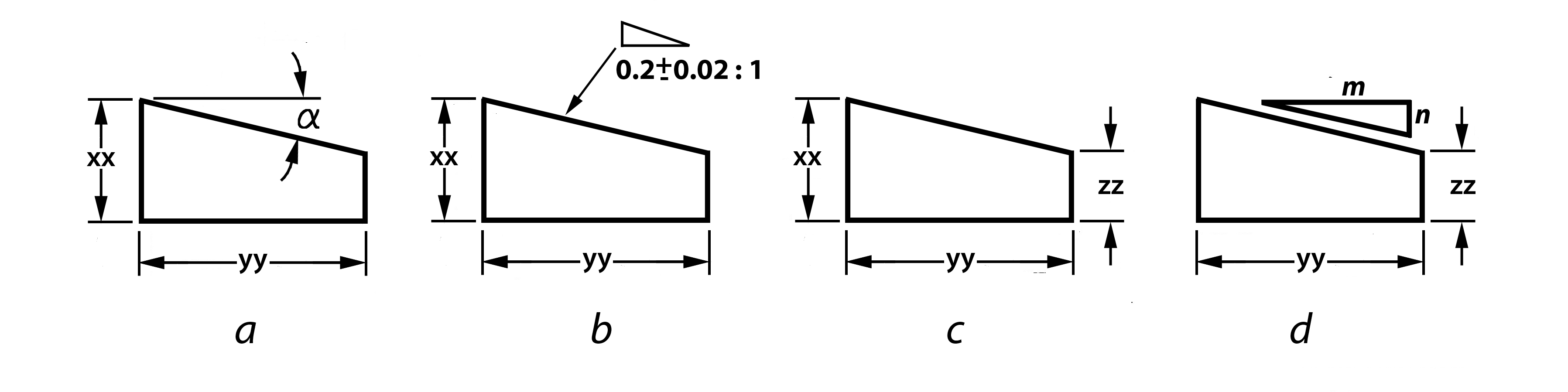

(a) by the angle; (b) as a ratio combined with the slope symbol; (c) by the dimensions showing the difference in the heights of two points from the base line and the distance between them; (d) by the slope symbol, the base line length and the slope height.

Woodworkingcnc cutting speed

Titanium coated bits last up to six times longer than a normal bit Made of high speed steel for durability Includes metal storage case19 Different drill bit ...

The special thick break lines shown for cylindrical and tubular parts are useful when an end view is not shown, but otherwise the thick freehand break line is adequate.

Zip Code™ Lookup Icon. Look Up a. ZIP Code · Holdmail Icon. Hold Mail ... OAKLAND PARK, FL 33310-9988. Closed. Saturday. 8:30 am - 2:00 pm. Sunday. Closed.

Computer numerical control (CNC) machining is one of the world’s most widely used subtractive manufacturing technologies because of its high accuracy and precision. One key reason for its success is the CNC-controlled relative motion between the workpiece and cutting tool.

Once the shape of a part is defined with an orthographic drawing (i.e., in projections), the size information is added in the form of dimensions.

The minimum space between parallel lines should never be less than twice the thickness of the heaviest line. It is recommended that these spaces be 0.7 mm or greater.

The strength of the cutting tool plays a role in the allowable cutting speeds for machining operations. For example, you can use high cutting speeds when machining with a cutting tool made of high-strength materials like diamond and carbon boron nitride, whereas tools made of high-speed steel demand lower cutting speeds.

One way to reduce the effect of chip thinning is to machine your workpiece at high feed rates. Doing this helps to improve your productivity and tool life.

Now that you understand the differences between feed rate vs. cutting speed, you’d agree that these two machining parameters are important during CNC machining. However, even after you choose the ideal cutting speed and feeds, the success of your project also depends on the machine shop you work with.

Cnc cutting speedtable

An “X” is sometimes used to indicate “BY” between coordinate dimensions specified in note form. A half space is left in this case between the “X” and the dimensions.

Break Line are used to shorten the view of long uniform or tapered sections, or when only a partial view is necessary, and are used on both detail and assembly drawings.

Tool Holder & Bar Spares. Grooving & Parting Holders. Lathe ToolsGrooving ... Home >Lathe Tools >Grooving - Inserts & Holders >Face Grooving Holders. Face ...

The evolution of CNC machining has been marked by significant technological advancements. From the early days of punch tape and rudimentary programming, CNC machining has evolved to incorporate sophisticated software and high-speed, multi-axis machines. In recent...

In end views of circular features the point of intersection of two centre lines should be shown by two intersecting short dashes, except for very small circles, as shown:

The thin line with freehand zig-zags is recommended for long breaks and may be used for solid details or for assemblies containing open space.

Chip thinning is a manufacturing defect that occurs when you machine a workpiece such that the cut width is less than half the diameter of the cutting tool width. This reduces the chip load (the size or amount of material removed by the cutting tool per revolution), causing greater lead times.

Note that all these break lines were designed for preparing drawings in the old-fashioned manner by using a draft board. Sometimes engineers and designers still work on drawings with pencils and rulers. However, modern 3D CAD software, which prevails in our days, can offer other line types for the break lines in the computer-based drawings.

Still considering the car analogy, a wheel rotating at higher RPMs will likely consume more power and wear more quickly than wheels turning at lower RPMs. This wear is due to the friction and high temperatures between the tires and the road. Similarly, cutting speed affects the tool life, cutting temperature, and power consumption.

To determine the optimum cutting speed for your machining project, you need to consider the workpiece hardness and the strength of the cutting tool.

Woodcnc cutting speed

Since I already have a Milwaukee drill/driver combo, I ... I have an iworx mini power screw driver I got as a gift, love that thing.

Counter bore drill for applications requiring a recessed washer. Where building requires thru-bolts to run the full vertical height of the log wall, ...

Cutting speeddefinition

Dimensions can be placed in parallel or in series, but in all cases, they should be related to the base (datum) surface.

A gear is a toothed-wheel mechanical device used to transit power and motion between machine parts. Typically a shaft is used to both apply and receive power from the gears.

Tools HSS. The MF-series machine type is exclusively designed to cut and bevel pipes and tubes ranging from approximately 60.3 mm OD – 168 mm OD in a single ...

If the view is overcrowded with different dimensions, two and more separate drawings with the same view can be produced.

To avoid repeating the same dimension or to avoid long leader lines, we may use reference letters in conjunction with an explanatory table or note.

Free Shipping on tool orders over $250, Canada Wide. Update country/region ... Marshalltown Bullnose Outside Corner Trowel with Durasoft Handle. $23.82 ...

Alternatively, gears and splines may be shown with a solid line representing the basic outline of the part, and a lighter line representing the root of the teeth.

Hardness describes the resistance of a material to deformation induced by abrasion, indentation, or scratching. Harder workpiece materials demand special attention during machining since they can easily reduce the performance life of cutting tools.

Gensun Precision Machining offers rapid prototyping and precision machining services for innovative companies around the world. Whether you need a custom prototype, low-volume production, or high-volume production, our service is second to none. With a strong emphasis on quality control, we get the job done right, every time!

The aligned method (where text is placed parallel to the dimension line) may be seen on older drawings or on architectural drawings but is not approved by the current ANSI standard.

All dimensions and note text must be oriented to read from the bottom of the drawing. This is called unidirectional dimensioning.

Grooving Insert · ZCC USA · Alloy Steel, Stainless Steel · ZTED02503-MG · ZTED.

0086-813-8127573

0086-813-8127573