Feeds and Speeds - Guide for beginners - speeds and feeds

There are two distinct circular shanks: SDS and SDS Max, used in Hammer Drill Bits and Chisels. The SDS and SDS Plus have a 10-millimeter shank, whereas the SDS Max has an 18-millimeter shank. In addition, there are a lot of adapters that let you use different types and sizes of drill bits.

Plunge rateCNC

A detailed analysis of tool damage can be conducted using a chart that correlates speed and feed with various types of wear. The vertical axis represents cutting speed (a primary factor in heat-related issues), while the horizontal axis represents feed rate (a key factor in load-related issues).

The key to maximizing both productivity and tool life lies in finding the “sweet spot” between speed and feed. While manufacturers provide speed and feed charts as a baseline, these are conservative estimates that often do not account for the numerous variables present in real-world machining environments.

CNCfeeds and speeds chart wood

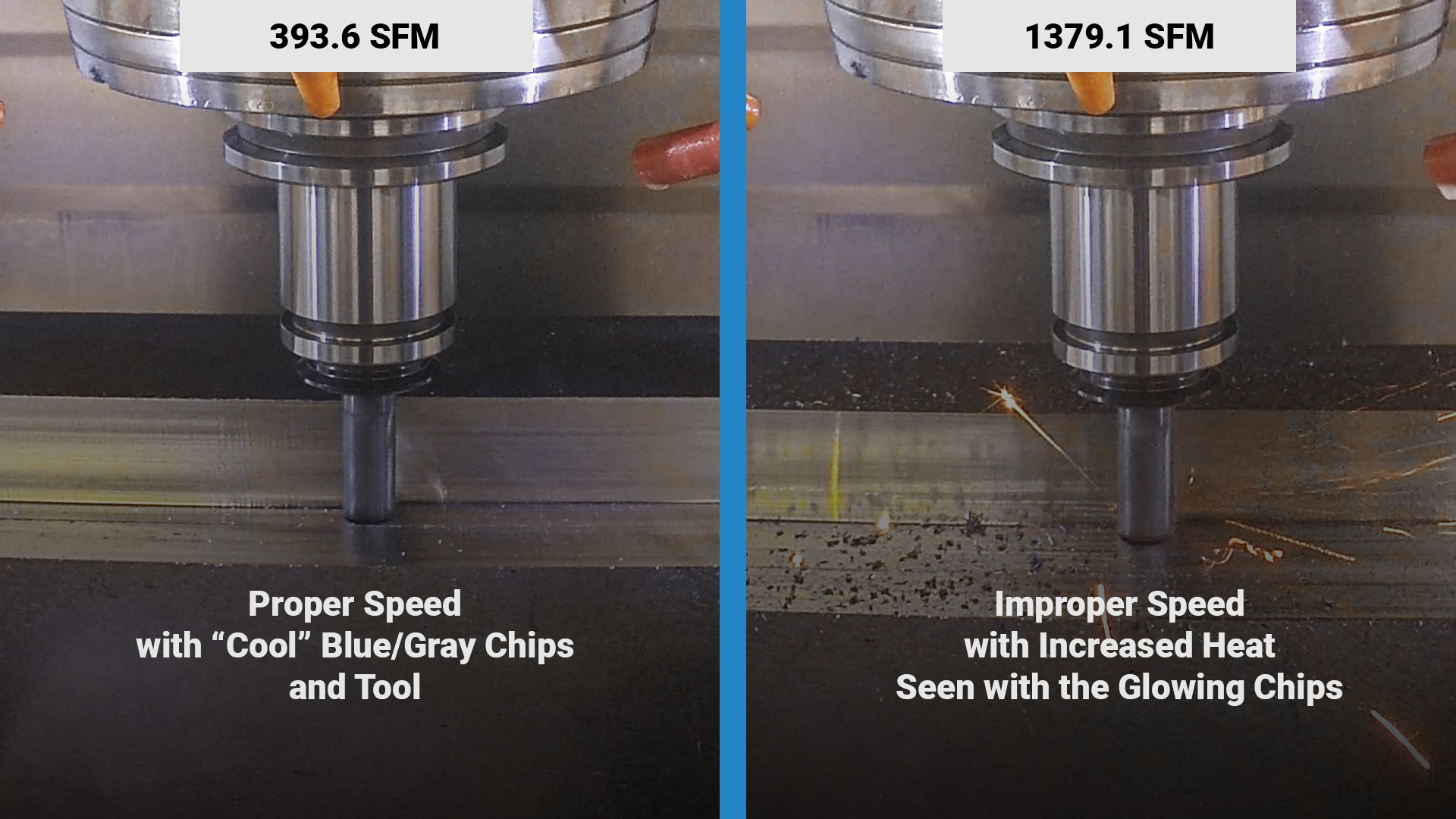

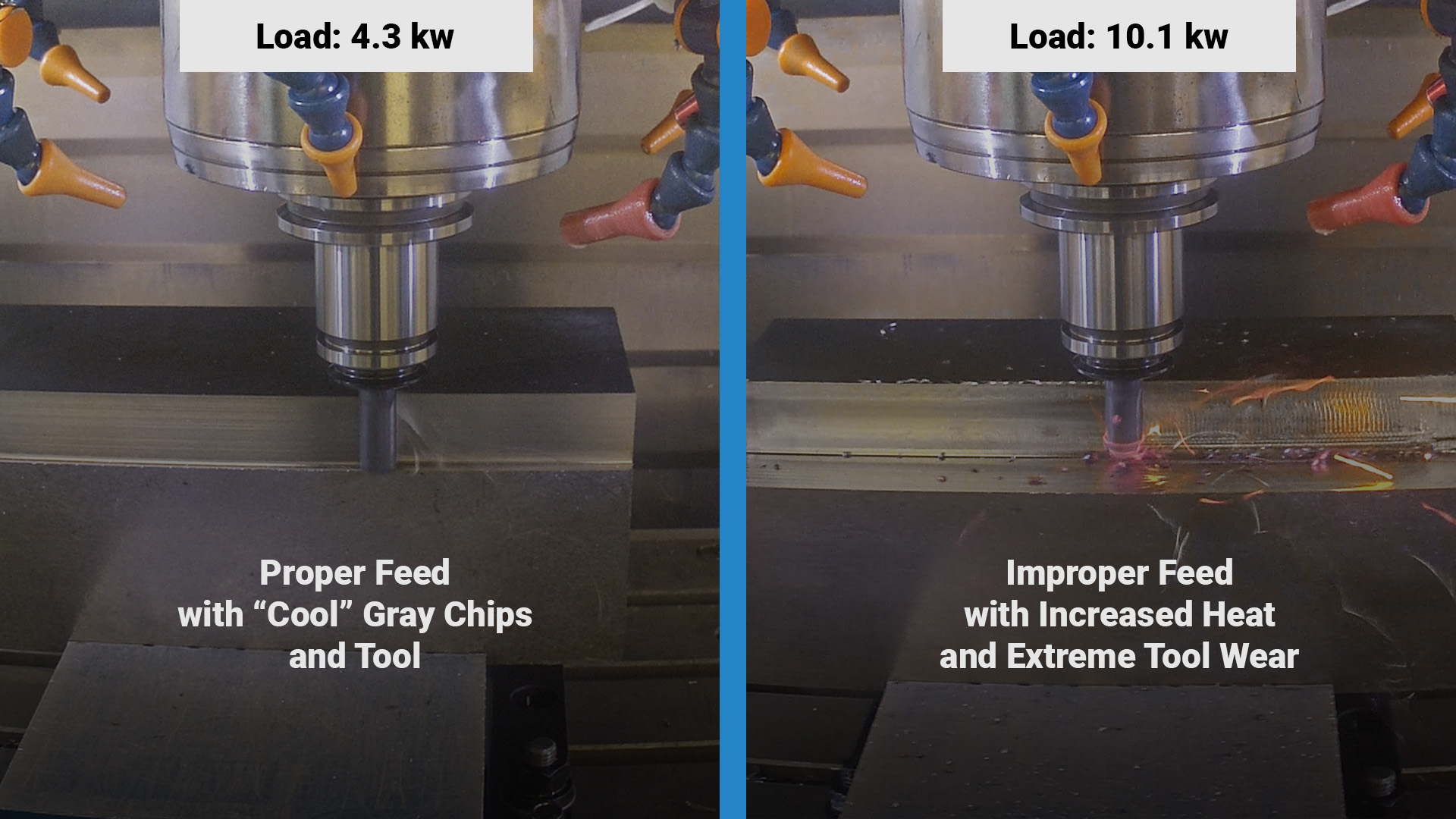

“We can think of speed as heat and feed as load and start that as our process of elimination and investigation,” Jason explains. This structured approach helps machinists systematically diagnose the root causes of wear and implement effective solutions.

Conversely, varying the feed rate while keeping the speed constant illustrates how different feed rates impact the load exerted on the tool. Excessive load can cause mechanical stress and lead to wear.

In the realm of CNC machining, tool wear and damage are perpetual challenges that can significantly impact productivity and tool longevity. The primary factors influencing these issues are speed and feed. This article delves into these concepts, providing CNC machinists with a detailed exploration of how to balance these parameters for optimal performance.

CNCRouter feeds and speeds calculator

Having holes with the correct diameter is crucial, especially if you use screws or other fasteners. Choosing the right drill bit size is the first step in getting the job done correctly.

One of the easiest ways to determine drill bit size is by examining the screws you are going to use. To do this, you should compare the diameter of your drill bit to the diameter of the screw to see if it's the best fit. Having the right size allows the head of the screw to penetrate the material without splitting the grain, while allowing the threads of the screw to join two boards together.

For a brief look at other causes of tool wear and strategies on prolonging tool life, refer to our article on “Maximizing Tool Life: 12 Strategies.” This resource provides insights and practical tips that complement the principles discussed here.

It’s important to note that RPM is a resultant value influenced by both the surface speed (or cutting speed, SFM) and the cutter diameter. Surface speed is a more precise and practical metric for CNC machining as it directly relates to the tool’s interaction with the material. Focusing on surface speed can provide a more consistent basis for optimizing machining parameters.

Remember to examine the screw and drill bit first before filling to avoid costly mistakes. If the hole is too large, it will compromise the connection between the materials and the screw.

Place your order online and receive order confirmation and shipping updates99% of our products are despatched same day from stock.

CNCspeeds and feeds formula

Machinists require reliable solutions to tackle intricate tasks efficiently. Indexable tooling provides exceptional flexibility, quality, durability, and delivers high-performance results. Customize your tooling for specific tasks by choosing the ideal combination of inserts and holders to optimize performance.

Anchors are available in various styles, sizes, and holding capacities that determine the maximum weight of an object that may be safely hung on it.

The diameter of the hole depends on the size of the drywall anchors. Therefore, comparing the drill bit's shank measurement with the anchor's front before drilling is necessary. Ideally, it should be the same diameter as the screw or slightly larger. The anchor's diameter is typically indicated on its box.

The drill bit should be almost the same size as the screw's center core, not the thread or spiral part. Some believe that drilling tiny pilot holes allows the screw to fit securely, resulting in a more stable bond. However, pilot holes that are too small might split or crack the object being drilled.

Balancing speed and feed is essential for optimizing CNC machining processes. By understanding and adjusting these parameters, machinists can enhance tool performance and extend tool life. This analysis underscores the importance of continual adjustment and observation to achieve the optimal balance.

CNCfeeds and speeds chart pdf

The shank is usually round or square, depending on the brand and type. Therefore, the shank must be the same size and shape as the drill's chuck to fit the drill bit.

Speed and feed are fundamental to the machining process. Speed, or revolutions per minute (RPM), refers to the rotational speed of the tool or the workpiece. Feed, on the other hand, is the rate at which the tool advances into the material. Synchronizing these two parameters is crucial; an imbalance can lead to rapid tool wear and suboptimal machining results.

CNC feedrate formula

Using a drill bit that is the same size as the anchor's body is recommended. It is essential to use a drill bit large enough to drill a hole in the wall, but small enough that you can insert the anchor with your thumb without using a power tool.

CNCspeeds and feeds calculator

“It’s not about taking your speeds and feeds to the maximum or bringing them all the way down to the minimum. It’s about trying to find that sweet spot that allows you to maximize your productivity and your tool life,” says Jason from Kyocera SGS, who works in Research and Development.

Concrete anchors and toggle bolts holes should be the same size. For example, 3/8 concrete anchor should have a 3/8 hole or be slightly larger. However, there is no need to use a drill bit for self-tap drywall anchors.

Explore our SGS branded high-performance and versatile solid round tooling options. Our quality tooling not only ensures precision but also minimizes downtime, allowing for increased material removal per hour. Explore a range of options including end mills, drills, routers, countersinks, and more to find the perfect tools for your specific needs.

Fasteners like screws and anchors are critical in small and large-scale building projects to secure various components together. For a more secure fastener, selecting the correct drill bit size is vital. Depending on your needs, you can buy a single drill bit or a whole set. Find the best drill bits for screws in our online store.

Additionally, investing in quality tools is crucial for achieving optimal results. Tools from the KSPT Group offer excellent high performance options for both indexable and solid round tools, providing durability and precision that can withstand the rigors of varied machining conditions.

To determine the size of the drill bit, you need to calculate the diameter of the hole that needs drilling. Drill bits with sizes between 1 mm and 20 mm in diameter are the most common drill bits.

“Always trying to work our speed and feed in balance to achieve that safe zone found in the center of this chart,” advises Jason. This balance is key to maintaining a safe zone that minimizes wear and damage and optimizes machining processes.

CNC feedrate chart

Material adhesion occurs at low cutting speeds and low feed rates, where the material has sufficient time and heat to weld itself to the cutting tool.

By varying speed while maintaining a constant feed rate, one can observe the impact of increased speed on heat generation. Higher speeds result in greater heat during machining, which can lead to thermal wear.

Drill bits will fit on a drill as long as the shank size and diameter are the same. However, fitting drill bits from different brands will depend on two things; the shank's type and diameter.

To ensure that the drill bit is the same size as the anchor minus the flange, hold the drill up to the anchor and measure the distance from its end to your drill bit.

Drilling is a must-have skill for both DIY home improvement and large-scale tasks. Therefore, it’s important that you choose the right size bill bit for each drilling task.

As machinists, we know that pushing beyond the provided parameters can sometimes yield better productivity, but it’s a balancing act. We have to tread carefully, adjusting parameters based on real-world results to avoid adverse effects. This delicate balance between caution and efficiency is what makes our work both challenging and rewarding.

Tool wear can be attributed to four primary sources: thermal, abrasive, chemical, and load. For simplicity, we can narrow these down to two main categories: heat and load. Understanding these categories is essential for diagnosing and addressing tool wear effectively.

All orders placed before 5:00pm Monday to Thursday and 3:00pm Friday will be dispatched on a next day carrier service. Carriage is free on all orders over £50 (Excluding VAT), if below £50 then next day delivery is £6.50

0086-813-8127573

0086-813-8127573