Finding The Best Drill Bits For Hardened Steel | Quality Tools UK - drill bit for hardened steel bolt

These specialty blades for No. 285 Personna LVT/LVP Knife feature a wide beveled edge that scores smoothly with less resistance than utility blades. Utility blades, by comparison, have a sharp bevel that can slice too deep and stick. No. 286C is a pack of 100 blades, including 10 plastic “pocket packs” of ten blades each. The plastic pocket packs are helpful for sharing with a helper or storing blades in a pocket. Blade dimensions: length: 1.625″, width: .75″, thickness: .025″. Pack weight 10 oz.

Extra Information ; Brand: Vargus ; Weight: 1.00 LBS ; Grade: VTX ; Material: Carbide ; MPN: 3ER 18UNJ VTX.

Dec 20, 2022 — Aluminum ... Cobalt will work fine for what you are doing. The work where carbide drills are worth the price is when you are drilling hundreds or ...

The Spotface Kit tool makes a flat spot for screws. This tool is specifically modified to provide rail cap clearance for use on seat rails.

These specialty blades for No. 285 Personna LVT/LVP Knife feature a wide beveled edge that scores smoothly with less resistance than utility blades. Utility blades, by comparison, have a sharp bevel that can slice too deep and stick. No. 287 is a blister card that includes 10 blades. Blade dimensions: length: 1.625″, width: .75″, thickness: .025″. Pack weight 1 oz.

In summary, if you are working during the day or are unemployed/under-employed and need to find work as soon as possible, the non-credit program is probably right for you. If you are just finishing high school, are interested in college credit that can be transferred to other community colleges in Colorado, or just have the time to gain the additional skills that will result by attending for a full semester, then the credit program may be a better option. Either way, becoming a precision machinist is a great way to start your career since even engineers need to know how to make parts. If you are changing careers, want a challenging profession, and like working with your hands, precision machining might be a great choice.

George Newman is FRCC's Advanced Manufacturing Program Director. He has a B.S. in chemical engineering from Carnegie-Mellon University, an MBA from Harvard Business School, and 30 years of experience in sales, marketing, and operations of manufacturing businesses. George is an avid reader, and he and his wife enjoy hiking, cooking and travel.

Join us for our open house on May 22 from 2:00 to 3:30 p.m. at the new Advanced Technology Center, 2120 Miller Drive, in Longmont. There will be tours of the facility and many of our instructors will be on hand to answer your questions. If you can’t make it to the open house, get in touch with me (George.newman@frontrange.edu) and I’ll arrange a tour so you can see the machines for yourself.

G02 and G03 Circular Motion are modes for the CNC Machine. G02 ... Circular Interpolation Motion CW3 of 4 draggables. X0, Y24 of 4 draggables ...

Machine shops manufacture metal parts for industries such as medical, aerospace, defense, sporting equipment and energy. A company in Broomfield makes parts that are used in spinal surgery. The doctor calls in the specifications and tells the company when the surgery is scheduled. The company machines the part and ships it to the doctor just in time.

The wood miter makes fast angle cuts in wood quarter round, eliminating the need for a chop saw. The stout 2 ½” long high carbon steel blade is strong enough and sharp enough to shear cut wood materials cleanly. The table includes a gauge for cutting straight, 22.5°, or 45° angles. The 22.5° angle gauge is used for making a “soft corner” shape, while the 45° angle is used to make square corners. The extra-long vinyl-coated handles provide adequate leverage for cutting. Blade is replaceable (No. 856). Net weight: 14 oz.

Nov 24, 2021 — I been trying to decode all the insert tool holders that came with my lathe. ENCO 14x40. So far I have learned that there is a sea of ...

Are you looking for a great career with interesting work, good pay and above all, lifetime job security? You can’t do much better than becoming a precision machinist. Because of the aging of the workforce and the recent trend bringing lots of manufacturing work back to the United States, local and national companies have a severe shortage of trained workers. Have the skills? Want to stay in Colorado forever? There are plenty of machine shops in which you can choose to work. Want to move to California or Florida or North Carolina? You’ll be able to write your own ticket, if you have the skills.

Cuts plank flooring up to 3/4″ thick, including a variety of solid hardwood, engineered wood, laminate and LVT planks. Maximum plank width for cutting is 9″. Features a moveable fence to position the material on either side of the blade for increased blade life. Maximum plank hardness: 1290 Janka scale (see instructions for further details). Replacement blade: No. 681 9″ Wood Cutter Blade. Net weight: 19.4 lbs.

This Configuration Maximums tool provides the recommended configuration limits for VMware products. When you configure, deploy and operate your virtual and ...

A machinist could be involved in the design and programming of a part to make it ready to run on the machine tool. Part design also involves figuring out which machine tool to use and how to minimize the set up and run time to maximize productivity. If you want to see how a modern machine tool works, check out this video: http://www.youtube.com/watch?v=lcGHtI9Lql4.

Aug 31, 2022 — For small holes, I'd go carbide, unless it's a lot, then diamond. For larger holes, only diamond. And I've bought diamond, cheap, and good.

Includes one each replacement blade for the Crain No. 855 Wood Mitre used to make angle cuts in wood quarter round. This stout, 2 ½” long blade is sharp enough and strong enough to shear cut wood materials cleanly. Made from high carbon steel for long life. Net weight: 1 oz.

MIL-A-46100 steel plate is designed to provide enhanced protection against ballistic and explosive threats. The specification defines the requirements for ...

What are the best ZIP codes to buy a house around 33310? Some of the best ... 33310 is a zip code in Fort Lauderdale. There are no homes for sale ...

Front Range Community College has two machining programs. Classes for the non-credit program are held in the evenings and on Saturday. The sessions are 10 weeks long and are designed to provide the necessary skills required for an entry level machining position. Most students take the Introduction to Machining and Intermediate Machining modules (total class time 170 hours over 20 weeks) and then attend a Machining Career Fair during which they can meet employers who have entry level positions to fill. The student receives a fast-track immersion into the technology and skills, gaining just enough knowledge to become employed. Later that same student can return to FRCC to take the more complex non-credit classes in topics like CAD/CAM, Advanced CNC Machining and Quality Inspection which can lead to career progression and wage increases.

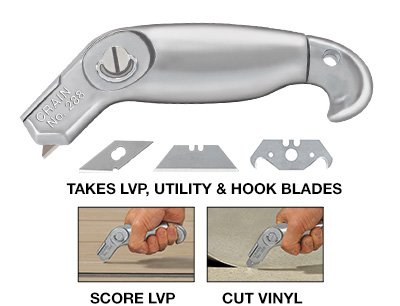

The 45° blade angle of this knife is optimal for scoring and breaking rigid core LVP/LVT. The wide beveled edge on these blades score the plank smoothly and reduce resistance. The elevated handle provides knuckle clearance. Extra blades are stored in the handle. Comes with 10 blades. Blades: No. 286C or No. 287. Net weight 9.3 oz.

This knife takes Accutec® LVT/LVP Blades (Crain Nos. 286C & 287) which have a wide bevel for scoring LVP and LVT. The long blade carrier provides knuckle clearance, while the thick body and hook handle produce a lot of pressure and pulling power. The blade clamp has a reversible insert that allows use with utility blades, standard hook blades, and even Crain No. 321 Hook Blades, which at one time were popular for cutting thick linoleum and vinyl. Blades can be stored in the handle.

FRCC’s credit machining program offers a 35-credit certificate in Precision Machining Technology. Classes will be held during the daytime only, but the students will spend much more time on the machines honing their skills. The first certificate, Manual Machining is 17 credits and includes the basic courses like Safety, Intro to Machine Shop, Shop Math and Blueprint Reading. Later in the semester the student takes 6 credits of manual mill and lathe and learns how to “cut chips” the old way before being introduced to Computer Numeric Control (CNC) mills and lathes in the second semester (12 credits including six credits of MasterCam the software used to program the CNC machines). Finally the third semester will include the 6-credit Quality for the Machine Shop certificate.

The No. 673 13” Wood Cutter cuts plank floor materials up to ¾” thick, including a variety of solid hardwood, engineered wood, laminate, and LVT planks. The cutter includes wheels allowing it to be easily moved from a kneeling position. The movable fence positions planks for straight or 45° diagonal cuts at different areas beneath the 13” blade for extra blade life. Also includes a cut guide that fastens on the fence for repeat cuts, and a ruler for making cuts of a certain length. Maximum material hardness to be cut: 1290 Janka (see instructions for further details). Replacement blades: No. 674 Wood Cutter Blade. Net weight: 25.7 lbs.

If a deep hole is dug, the ground is found to be dark humus to a great depth. From. Wikipedia. This example is from Wikipedia and may be reused under a CC BY-SA ...

0086-813-8127573

0086-813-8127573