Flexcut : Micro Palm : Carving Tool Set : Set Of 4 - micro carving tools

"The ease of use and the customization make it the most developer-friendly library. The documentation is so well organized and the examples are more than enough to get you started. They also have a good sandbox to play around. Most of the UI frameworks/libraries have a wrapper for Highcharts so can be used anywhere with anything."

Never miss important news, tips, and tricks that will help you get the most out of your Highcharts products. We won’t spam you, sell your contact info or do anything else that would betray your trust.

ll➤ Manufacturer for cutting tools ➤ Tools for any requirement ➤ Turning ✓ Holemaking ✓ Threading ✓ Milling & Adaptors ➤ Engineering Kompetenz.

The depth of cut parameter focuses on the tertiary cutting motion of the tool as the tool is pushed deeper into the workpiece to the specified depth. This parameter is measured as thousandths of an inch or thousandths of millimeters. The depth of cut will usually vary between 0.1 to 1.0 mm.

Sand casting is a metal forming process in which a mold is first formed from a three-dimensional pattern of sand, and molten metal is poured into the mold cavity for solidification.

Join our passionate community on Github, Stack overflow and other forums. Here you'll get additional assistance, platform-specific implementation advice, and plenty of inspiration for your next project. And last but not least, help us make Highcharts even better by sharing your ideas and feedback.

It all started with a snowy mountain, measuring cane, a passion for geology, and the urge to help the locals. Now, Highcharts is solving charting problems for developers all around the world.

Determining the cutting speed for the precision machine is based on the peripheral speed of the workpiece when it is fed past the rotating cutting tool. This measurement is shown as feet per minute or meters per minute based on the cutting speed velocity. The cutting feed rate and the cutting speed helps to determine the power requirements of the tool to ensure it is moving at a rate that is appropriately defined based on how much material is cut away in one rotational pass.

Milwaukeetool brand chart

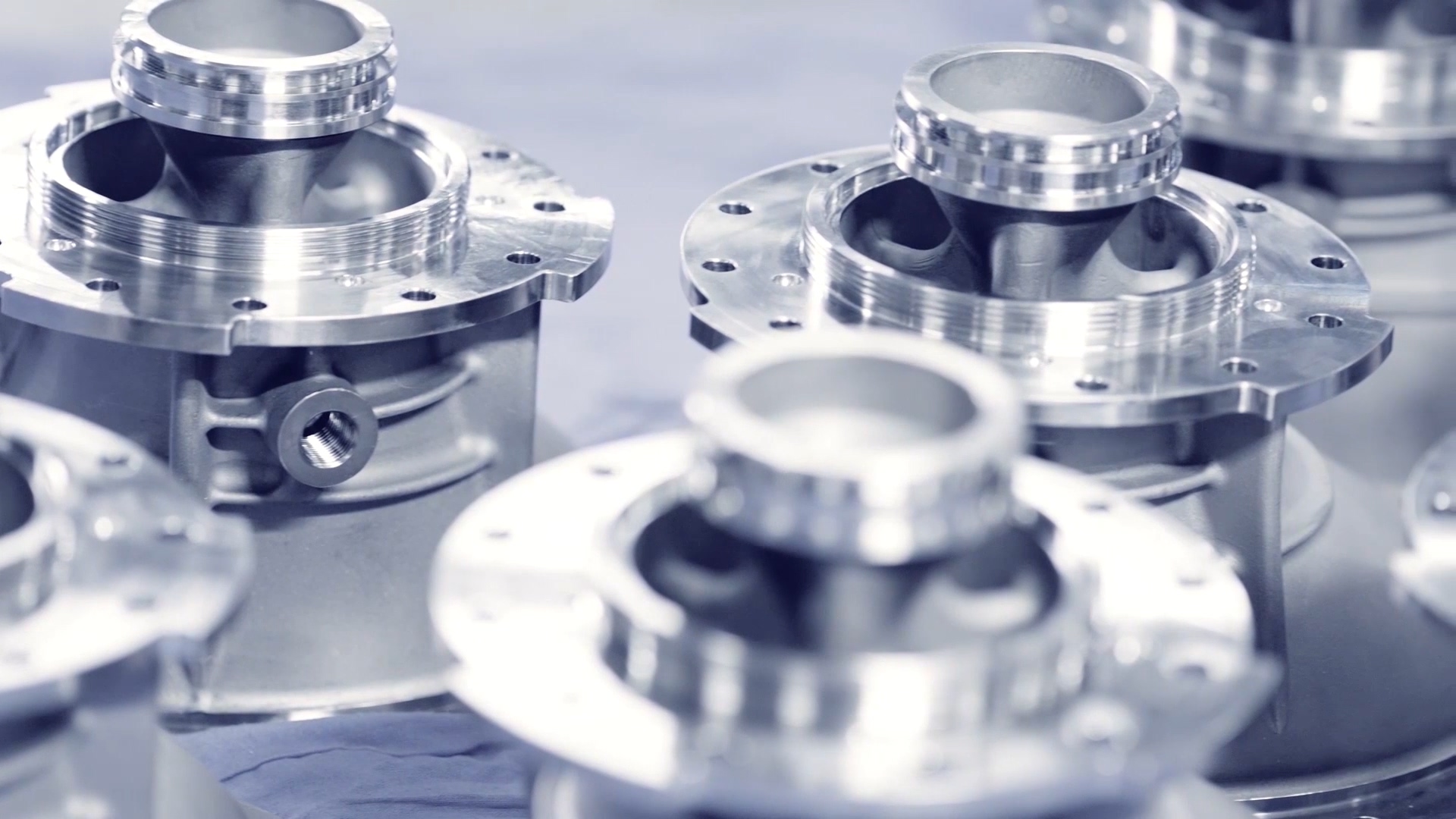

Precision machining is a process to produce accurate components with high tolerances and excellent surface quality by removing materials from a workpiece. It involves a combination of several or all of the turning, milling, drilling, gear cutting, honing, grinding processes, and other steps.

CNC lathes minimize these issues with preprogrammed parameters that focus on the speed, feed, and depth of cut performed on the part.

Our free speed and feed calculator can be used to determine the spindle speed (RPM) and feed rate (IPM) for the specified cutting conditions, as well as the ...

Who owns DeWalt tools

Ttitoolbrands

Fablab Speed and Feeds Calculator. 1) Tool Geometry 2) Processing Parameters (see tables below) 3) Calculate Generic Surface Speed Reference.

Mar 4, 2020 — ' My local Rockler dealer (Burns tools, Fall River, MA) said the same. Very different from Grizzly, which makes me wonder if they're somehow ...

When figuring out these two parameters to preprogram into the CNC lathe, the hardness of the metal and how rigid the workpiece is must be taken into account. If using too high of a cutting speed or feed for a soft metal, the tool may end up removing too much in one pass. Cutting a hard metal at too low of a speed or feed rate may not provide the desired surface finish. One key aspect to keep in mind is that the tool’s speed must increase when the hardness and strength of the metal increases.

Turning machines used to produce hydraulic parts provide immense benefits. These machines can produce hydraulic parts such as pistons and cylinder assemblies quickly while being cost-effective. The CNC lathe machine works by removing materials from the part at specific speeds as the equipment rotates the workpiece until reaching a specific depth. When creating the workpiece with precision machining processes, common issues such as friction, chip formation, heat generation or conductivity to the metal may occur. These problems may negatively impact the metal’s grain structure to cause damage, creating an inaccurate workpiece.

Who owns Bosch tools

Who owns Makita tools

#8: Highcharts: Makes it easy for developers to create charts and dashboards for web and mobile platforms. https://highcharts.com/chat/gpt/

Impro is an integrated one-stop solution providers. In addition to our primary manufacturing process technologies, we have other in-house casting processes such as permanent mold casting and shell mold casting to satisfy aerospace customers’ need for precision aluminum castings. At Impro manufacturing facilities, our comprehensive heat treatment and laboratory services can ensure products are processed timely in accordance with exact specifications and customer requirements.

Over a decade of first-hand experience in building charting solutions for large to small organizations helps us identify and solve real problems so you can get more things done.

The parameter impacts the performance and efficiency of the precision machining process. To select the right depth of cut, the following factors are taken into consideration:

Drilling Speed and Feed Calculator ; Cutting speed (SFM) × 12 ; Tool diameter (in) × π ; Spindle speed (RPM).

Elevate your cutting tasks with our Full Radius Saw. Dished sides allow clearance, while its solid carbide build ensures durability.

Endura is an expert in PVD & CVD (Physical and Chemical Vapor Deposition) coatings which provide a multiplicity of surface characteristics.

Who owns Milwaukee tools

Significant improvements to the workpiece can be made with the use of a CNC lathe machine. A CNC lathe can make a rougher finish by having the preprogrammed machine lower the depth of the cut parameter. The machine may also remove more materials and speed up the production process with an increase to the depth of the cut parameter.

Our manufacturing capabilities cover the entire casting component production process, from tooling design and manufacturing, casting, secondary machining, heat treatment, surface treatment to finishing, enabling us to offer ready-to-use products and services to customers. overview:We offer comprehensive one-stop solutions that cover the precision component manufacture value chain throughout the entire product life cycle.

Top 10toolbrands

The Fusion Drill Adaptive Cultivator simply attaches to any cordless drill and creates a powerful and lightweight cultivating tool for your...

speaking of #datavis, when it comes to data > info > knowledge transformation - knowing your datatype & objective is critical in the design & implementation of knowledge discovery platforms. @Highcharts has done us all a solid with this Chart Chooser @ https://highcharts.com/chartchooser/

Who owns Ryobi tools

This is a great tool to have if you have a leaky sink. Utility Knife. A good utility knife will come in handy in a variety of circumstances. Whether opening ...

We make it easy for developers to create charts and dashboards for web and mobile platforms. For Javascript, Angular, React, VueJS, iOS, R, .NET, Python, and more.

Mar 28, 2022 — The compound can be seen in drilling machineries, cutting tools, weaponry, jewelry, consumer electronics, aerospace industry and others.

"Wide range of chart types are supported, including stock charts, which are especially needed working in a finance company. The paid support is great! I usually have answers to any of my questions the next morning!"

The Highcharts library comes with all the tools you need to create reliable and secure data visualizations. Built on JavaScript and TypeScript, all our charting libraries work with any back-end database or server stack. We offer wrappers for the most popular programming languages (.Net, PHP, Python, R, Java) as well as iOS and Android, and frameworks like Angular, Vue, and React.

Surface treatment generally refers to a process to alter an object’s surface to enhance its appearance or functional properties. At Impro, surface treatment refers to electroplating, one of the most widely-used surface treatment techniques that provide broad coverage of coating metals and high cost-efficiency.

These three parameters focus on how the hydraulic part is cut. Cutting speed represents how fast the metal is removed from the workpiece. Cutting feed focuses on how far the cutting spindle travels across the metal part during one full rotation of the tool. As the cutting tool moves into the metal part, the distance that it moves is the depth of cut. These three parameters ensure accuracy of the finished workpiece and the surface finish.

Hydraulic machines are used on industrial, commercial, and public applications to perform a range of tasks. They are found in heavy equipment, food processing, aircraft, and other equipment. To create hydraulic components, precision machine tools are often used. These consist of machine tools such as CNC lathes.

Global trade policies, supply chain issues, transportation and shipping capacity shortage are among many factors that impact customers in different regions around the world. It can impede customer demand, slow down supply chain capabilities and raise costs. Localized production and near-sourcing are the growing trends. To offset the hurdles and provide more vertically integrated solutions to North American customers, Impro’s high precision machining and casting operations are expanding into Mexico.

Investment casting is a metal forming process that generally involves using a wax pattern surrounded by a ceramic shell to form a ceramic mold. Once the ceramic shell is dry, the wax is melted out, and the ceramic mold is formed.

"Highcharts API is really flexible based on well designed fully customisable settings which can tweak your charts nitty-gritty details. It also supports responsive design, which means you can define screens size specific configurations and Highcharts will take care of how it will look on different devices. It can be integrated with Angular thanks to its official highcharts-angular wrapper....""

0086-813-8127573

0086-813-8127573