Flush Trim Router Bit | 1/2 Shank | 1/2 Cut Dia | 2 Flute - 1 2 inch router bit

Electric HandEngravingTools

Many industries have need of specialized engravers, for instance those who make dies, who cut stones and glass, and others who carve reliefs. Though a goldsmith might call on a specialist for certain jobs, it is useful to have a general understanding of the technique, shop for proper equipment and sufficient skills to use gravers for simple everyday tasks at the bench.

These bits are also known as multi-step bits or unibits, and they are unique in shape. They have multiple cutting edges and become progressively larger, meaning you can make holes of different sizes with the same bit. These perform the best when drilling automotive panels or thinner stainless steel sheets. Some are gold-coated to reduce friction.

This tool has a flat base, or ÒbellyÓ that can be used to carve away unwanted metal, as for instance when removing excess solder. The cross section can be trapezoidal (figure 10.21f and g) or a rectangle (not shown). This is also the tool used to make decorative wiggle cuts. It is the practical workhorse of the graver family, being used less for ornamentation than shaving, scraping, and cutting textures. Flat gravers are available in widths from 0.2 mm to 5 mm.

It is customary that graver blanks are furnished in a length sufficient to accommodate the largest hand. This means that the rest of us must start by shortening them. Grasp the tool vertically in a vise with the unwanted portion of the tang projecting up. Strike a vigorous blow with a steel hammer sideways against the tang and it will snap off cleanly. To prevent the tip from shooting across the room, catch the broken off part in a towel or rag held against the vise.

Illustrated at 10.21c, this graver is a slim, straight-walled version of the onglette. It is difficult to control on curves and rarely used by itself, but it cuts deep hair-thin lines. It is often used to add delicate embellishments to figures cut with other tools.

Before drilling the larger, final hole, create a smaller hole with a bit from the list of best drill bits for stainless steel. A pilot hole will guide your bit and keep it from drifting or skidding across the surface and causing damage.

If you need high-quality bits for your next automotive or stainless steel project, look for USA-made specialty automotive bits. ROGO Fastener has some of the best drill bits for stainless steel projects. Check out our excellent quality drill bit products on our website.

Automotive work often involves drilling holes through stainless steel. Stainless steel is hard and resilient, making it an excellent choice for automotive components. However, drilling through stainless steel requires the right precision tools to get the job done. Whether you're a DIY enthusiast or a professional mechanic, knowing the best drill bits for stainless steel can make all the difference in your work.

Handengravingtoolsformetal

This popular shape is shown in two sizes in 10.21a and 10.21b. The sides curve slightly outward from a top edge that is flat and can range from one to four millimeters wide. This tool offers great versatility, cutting a thin line with a light stroke and widening as it is rolled on its side or pressed more deeply into the sheet. It is preferred for cutting letters because of the ease with which it cuts a line of increasing width

Carbide is a compound of tungsten, carbon, and other elements. It is perfect for high-speed drilling operations and maintains its sharpness under heavy workloads. It is precise and efficient and works very well in automotive applications.

The belly or underside of the graver is ground so it shows two symmetrical facets. If the tool was turned over, these might be said to resemble the roof of a house. The angle between these two facets will be between 30 and 60° depending upon the hardness of the material to be cut. A narrow tip cuts a finer line but is more fragile.

Toolsfor Engravingmetal

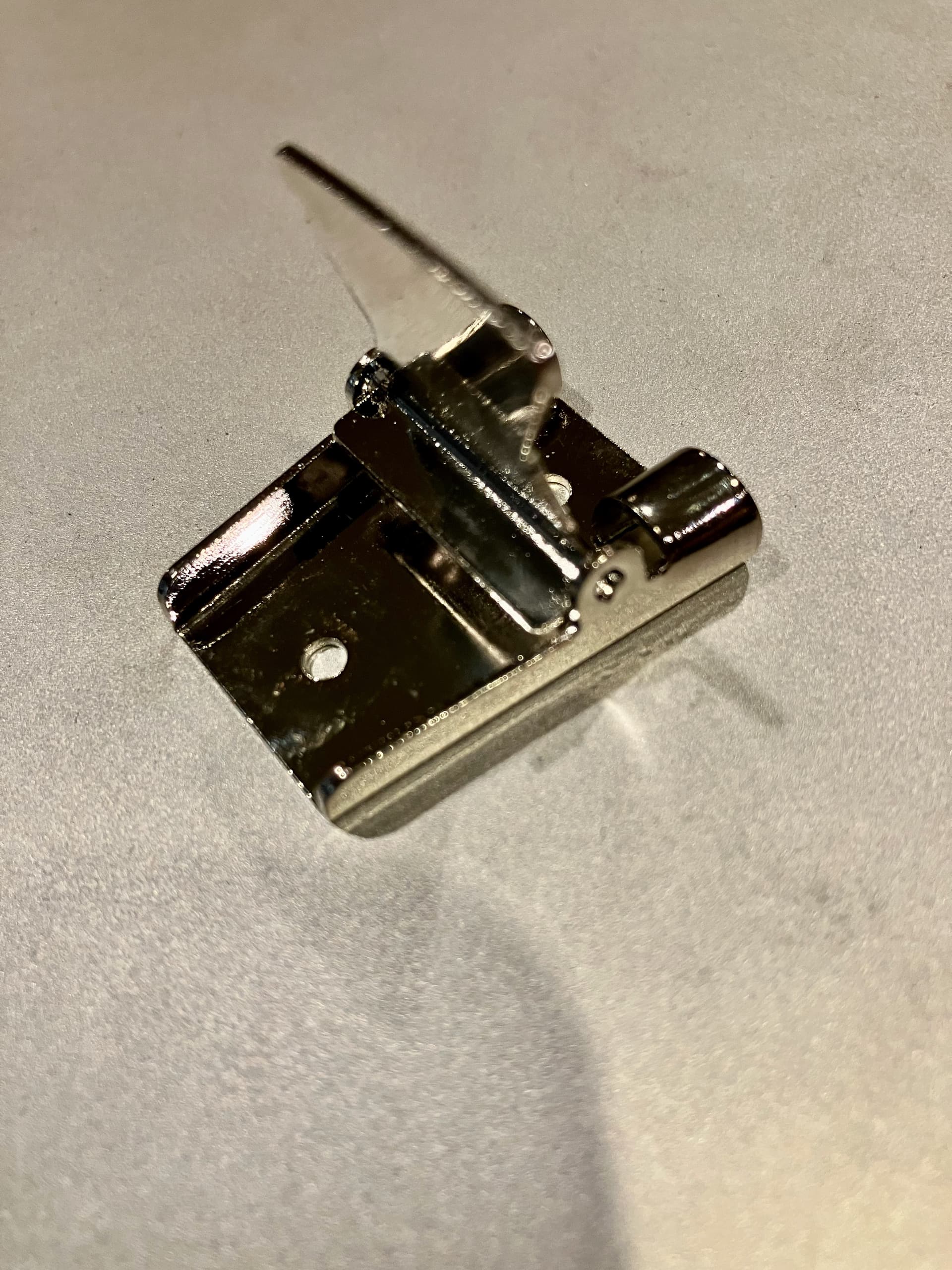

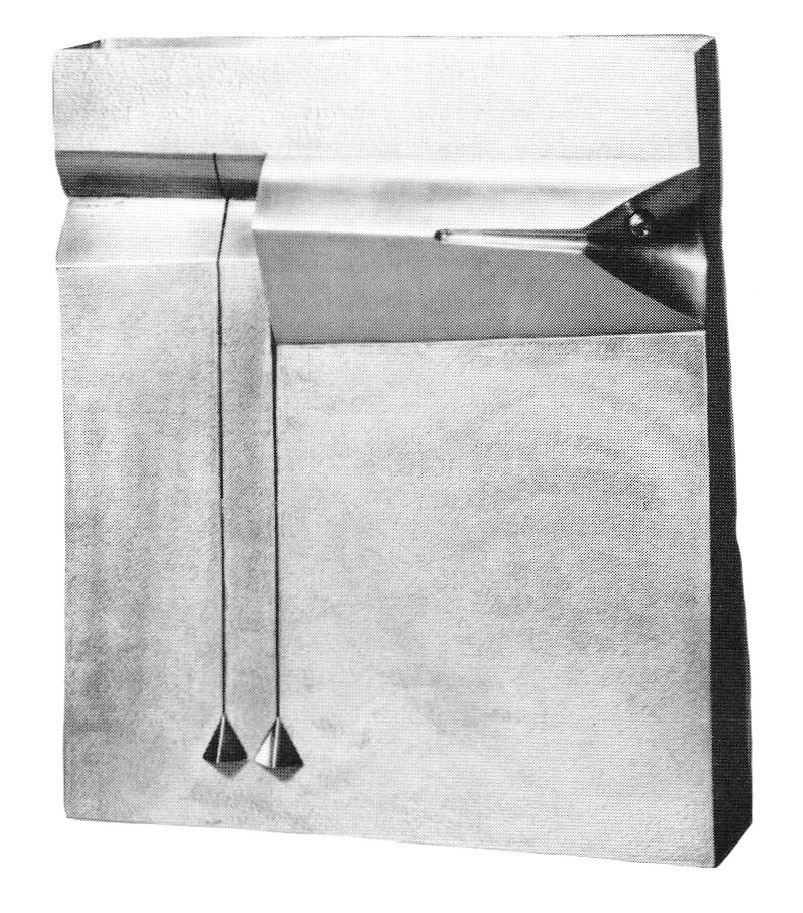

a) small pointed (onglette) graver. b) wider pointed graver c) knife graver d) facet graver e) ovel graver f) flat gracer with wide rib g) flat graver with small rib h) rounded grave i) rounded graver with small rib j) line graver

The face of the tool is then ground to a slope, typically around 45°, again depending on the material being cut; the finer the slope, the more delicate the tool. It might help to visualize a pencil point. If it is made very long and pointy it makes a fine line but often breaks in use.

The angle of attack is important to achieve a controlled and uniform cut. If the angle is too steep the tool digs itself into the sheet making it impossible to push it forward. The effort to overpower a buried tool can result in a loss of control and a broken tip. If the angle is too shallow the point never gains purchase on the sheet. There is no chip formed and no cut made. Because the tip of the tool is not caught by the metal, the tool easily slips, creating a nasty scratch.

Tool used for engravingcrossword clue

You assume all responsibility and risk for the use of the safety resources available on or through this web page. The International Gem Society LLC does not assume any liability for the materials, information and opinions provided on, or available through, this web page. No advice or information provided by this website shall create any warranty. Reliance on such advice, information or the content of this web page is solely at your own risk, including without limitation any safety guidelines, resources or precautions, or any other information related to safety that may be available on or through this web page. The International Gem Society LLC disclaims any liability for injury, death or damages resulting from the use thereof.

Proper shaping and sharpening of gravers is as important as it is difficult to describe on the printed page. The following description should be supplemented with practice and experimentation. Refer to figure 10.22, an onglette graver, for the following instructions. In general these same steps will be used for other shapes, though the angles of each tool differ slightly.

One of the best drill bits for stainless steel is diamond drill bits, which have a diamond encrusted tip that lets the bit easily cut through hard materials. These bits tend to be expensive, but their longevity and superior performance can make them a worthwhile investment.

This tool looks at first glance like a flat graver, but closer examination will reveal delicate lines cut lengthwise into the belly. These cut fine parallel lines into the surface, an effect that is used to ornament an otherwise plain surface while simultaneously protecting it from wear and fingerprints.

Engravingtoolsforwood

Both belly and face surfaces should be perfectly flat like the facets on a gem. This will insure that the angles where the faces meet are straight and crisp, which in turn is what makes the tool sharp. Grinding is usually done on an oilstone, working in a circular stroke, first on a coarse stone and then on a finer one. When the surfaces are correct - check with magnification - shift to a polishing stone like Arkansas or a fine abrasive paper. Follow this with a few strokes on a hard leather with a polishing powder to create a mirror bright finish.

This metal is exceptionally strong, durable, and aesthetic. In the automotive industry, it is most often used for fasteners, brackets, exhaust systems, engine components, and body panels because it can withstand environmental exposure, high temperatures, and mechanical stress very well.

Choosing one of the above bits will help ensure your job goes as planned. Trying to drill stainless steel with other types of bits won't work and could damage what you're working on.

Tool usedinengravingDaily Themed Crossword

Test the sharpening by sliding the tip of the graver along your thumb nail. A properly sharpened tool will stick immediately while an improperly shaped tool will slide off. There is no point in going to the metal until the tool passes this test. Cutting with a dull graver is tedious, uncontrolled and almost certain to ruin the work.

Stop drilling periodically to let the piece cool down. This is especially important if the part you are working on is incredibly thick. Clean any debris or chips away from the hole with compressed air or a brush.

This is the stout sibling of the wide onglette, figure 10.21d, used to make bold cuts in tough metal. The side surfaces form an angle of 100¡, with the upper sides being parallel. The width of the back can be between 1.5-3 mm.

This tool, shown at 10.21e can be considered a slim version of the onglette, but in this case the pointed oval is not truncated with a flat spine along the top. In practice this shape offers a blank that is ground as needed to create a tool to shave metal from within tight enclosures. This is the tool, for instance, that is used to carve a seat for a stone inside a bezel wall.

Engraving Tool forStone

Use consistent pressure when drilling, but don't press too hard. Too much pressure can lead to overheating or premature wear.

Reshape the tang by grinding, either with a bench grinder, sanding machine, or appropriate wheels on a flexible shaft machine. The graver is secured by friction into a handle in the same manner as a file; secure it into a vise and tap the handle into place with a mallet. As the tool becomes shorter through numerous sharpenings, a long handle is replaced by a shorter one. Though the grip might feel a little awkward at first, it will become more comfortable with experience. If your hand muscles get cramped during engraving the tool is too short and should be replaced.

Radiator tanks, coolant pipes, and other cooling system components are often made of stainless steel, and though it's less common, some brake calipers, rotors, and brake lines are, as well.

Ganoksin is the worlds largest educational website for jewelry making and metalsmithing. Our community is the heart of Ganoksin. It is the oldest and largest jewelry making community on the web.

Getting the best results when drilling this type of metal involves planning, having the right materials on hand, and using proper techniques. To get the job done right, you'll need:

The best drill bits for stainless steel parts depend on the job, but one thing that is for sure is you need to use quality bits specifically designed to handle such a hard metal. Inferior tools could break, cause damage to the automotive components, and lead to frustration. You need bits that offer superior performance, precision, and durability.

Engraving tools are miniature chisels made of hardened steel. They are chip forming tools and subject to the same forces described in Chapter 5. In proper engraving a sharpened tool is set against the metal at a specific angle and pressure applied both downward and forward. The tool buries itself into the sheet, forms a chip, and pushes that curl of metal ahead of it as it cuts.

Gravers are usually sold with preshaped tips, but these angles will need to be reworked before the tool is used. Gravers can be purchased from jewelry supply companies in the shapes shown in figure 10.21.

It's important to know the properties of stainless steel to really understand which bits to use. Stainless steel is a corrosion-resistant alloy made of iron and some nickel, chromium, or other elements. It has a protective oxide layer on the surface, which helps it resist rusting, staining, and corrosion. There are several finishes and grades of stainless steel, but the most common are austenitic and martensitic stainless steel.

Engraving tools, called gravers, are precise instruments. They must be made from top quality steel, shaped and sharpened to specific angles, and fitted into handles that provide comfort and control. Commercially available gravers are made from a highly refined fine grained tool steel. A high speed steel is to be recommended for working harder materials and to have the greatest possible durability; there are even engraving tools with carbide cutting tips.

This name is deceiving because the tool itself, pictured in two sizes at 10.21h and 10.21j, is not round. Nevertheless, the groove it cuts is a round-bottomed trench and it is from this the name is derived. As shown, the side walls can be either parallel or sloped. This tool is among the easiest to control and is therefore useful for all kinds of decorative work.

Many industries have need of specialized engravers, for instance those who make dies, who cut stones and glass, and others who carve reliefs. Though a goldsmith might call on a specialist for certain jobs, it is useful to have a general understanding of the technique and sufficient skills to use gravers for simple everyday tasks at the bench.

One excellent choice is cobalt bits. These are some of the more popular options for drilling in automotive settings. Cobalt bits are made from high-speed steel alloyed with cobalt, making them extra heat resistant and hard. They tend to maintain their sharpness and can withstand high temperatures without issue.

Regularly sharpen and inspect your bits to help them stay working consistently. Caring for your tools the right way helps prevent accidents and tool failure on the job.

EngravingtoolsforBeginners

One way to reduce friction, prolong the life of your bits, and dissipate heat is to use a cutting fluid or lubricant. These include straight oils, soluble oils, misting oils, and graphite-based lubricants, among others.

Titanium is known for its resistance to wear. Sometimes, these bits are made of an alloy or coated in titanium nitride. These have better corrosion resistance, less friction, and heat resistance, making them perfect for stainless steel. Titanium coatings, specifically, reduce friction during drilling. This both reduces heat and results in a smoother hole, as well as longer tool life.

The first step is to narrow the area adjacent to the tip for 1-2 centimeters (1/2 - 3/4 inch). This will allow better viewing of the working tip of the tool and facilitate sharpening since there is less metal to be removed. Use a stone to cut away at least half of the top section at the tip, creating a gentle arc as shown. This edge should be made smooth because your fingers will be resting on it while cutting. Do not go too far back because this will weaken the tool.

It's important to clamp or secure the piece you are working on to minimize the risk of breakage and ensure that your hole is accurately placed.

Stainless steel is also used in engine components, such as valve springs, valves, intake and exhaust manifolds, fuel injector components, and cylinder heads. Many fasteners and bolts are made of stainless steel to provide more reliable fastening, especially in areas exposed to road salt, moisture, and chemicals.

Gravers are sold in their hardened state and any grinding should be done in such a way that this temper is preserved. Touch the tool lightly to the grinding wheel, dipping it frequently into water throughout the process to prevent it from overheating. If the steel starts to show color the temper has been compromised.

The proper angle will depend on the shape of the graver, the quality of the desired line and the metal being cut. Understanding and responding to these factors requires a sensitive touch and considerable experience.

0086-813-8127573

0086-813-8127573