Flute and Piccolo Head Corks - flute cork

Cemented carbide, coated carbide, cermet, ceramic and other hard material inserts have the cutting edge honed so as to prevent fracturing in the machining.

For turning operations, mainly G-class (sometimes J-class) or M-class inserts are used. Inserts with tolerance classes other than G, J and M are mostly used on face milling cutters.

2022114 — Indexable turning, milling, and drilling tools are often the best choice for productive, cost-effective machining. Learn more about carbide ...

Carbon fiber is actually quite easy to cut. Your router doesn’t need a ton of torque or speed—my router’s minimum speed is actually too fast!

I’ve tested all sorts of settings. I’ve gone as high as 800 mm/minute with a cut depth of 0.5 mm. I broke a $20 bit from Carbide 3D on that cut. I’m not sure the speed was the problem, though. My 3 mm carbon fiber sheet came loose during that cut, and I assume that put a lot of stress on the bit.

Discover the Jotul gas fireplace inserts. Modern and traditional design.

Apr 28, 2023 — Reaming is an essential manufacturing process used by machinists to achieve precise sizing and finishing of drilled or bored holes. By using ...

This is the symbol that represents the clearance angle of an insert. An insert with 0° clearance angle, which is shown by symbol N, is called a negative insert. An insert with a clearance angle other than 0° is called a positive insert. Many turning inserts have clearance angles shown by symbols P, C and N.

The math says I should be running my router at 5,000 to 6,000 RPM. My Dewalt router can’t run that slowly. I believe the lowest setting works out to around 20,000 RPM. Too much speed generates heat, and it cuts out dust instead of chips. The heat could be bad for the epoxy, but it hasn’t been problematic yet!

DB Rowley · 2019 · 16 — Oceanic axial depth and age-depth distribution of oceanic ... axial depths predicted by this best-fit relationship and the actual axial depths.

The insert geometry is represented using letters of the alphabet. A wide range of geometries are listed as standard for example; triangle, square, round, polygon and rhombus.

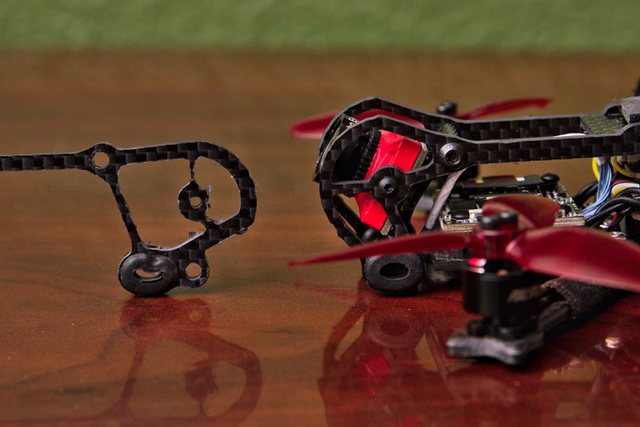

I am not an expert. I have cut about three quadcopter frames’ worth of parts. Not three complete frames, though. My design process is iterative, so I’ve been replacing parts as I make improvements.

This symbol represents the direction in which the insert can machine. If the insert can be used for both left and right (thus neutral) then the symbol is generally omitted.

Waltertools catalog pdf

For turning operations, mainly G-class (sometimes J-class) or M-class inserts are used. Inserts with tolerance classes other than G, J and M are mostly used on face milling cutters.

I don’t know why, but I thought this would be a longer blog! I guess there’s not much to say. These are my feed rates. These are the bits I’m using. This is the carbon fiber I’m cutting. The cuts are clean. Done. Right?

This symbol represents whether or not the insert has a chip breaker. It also refers to whether the insert has a hole or not. A negative insert can have one-sided or double-sided chip breaker.

I only have a 1/4" shank router (the Dewalt fixed/plunge one) I generally use a 3/4" straight bit and my instincts are just to get a freud 3/4" ...

Waltertools catalog

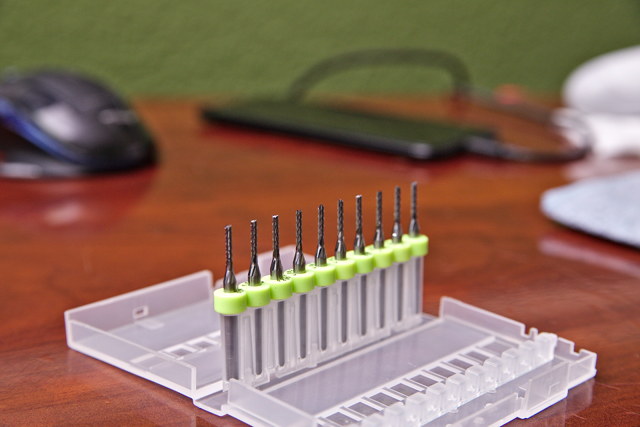

I’m using 1/16” fishtail endmills that I bought on eBay. They’re about $20 for a pack of 10. I haven’t broken one yet, but I will be sure to keep pushing my feeds higher until I do!

For the inch coding method, the diameter of an inscribed circle is shown by a numerical symbol. For example, an inscribed circle of 3/8 inch (9.525mm) is represented by the symbol 3. An inscribed circle of 4/8 inch (12.70mm) is shown as 4.

This represents the corner radius (nose radius) of an insert. It is standardized in intervals, for example after 0.4mm with intervals of 0.4mm, and after 4.0mm in intervals of 0.8mm.

Waltertools distributors

Chip breakers play an important role in chip control. Cutting tool manufacturers employ their own breaker geometries and as such the symbol is optional.

The 400x500 mm 3K carbon fiber sheets are definitely high quality. I ordered those from GetFPV.com. I ordered another sheet of 3 mm 3K carbon fiber from Hobby King. That sheet hasn’t arrived yet, and they don’t stock 400x500 mm sheets. Their prices are quite a bit better, though. You get about 40% more material for your dollar at Hobby King.

This is the symbol that represents the clearance angle of an insert. An insert with 0° clearance angle, which is shown by symbol N, is called a negative insert. An insert with a clearance angle other than 0° is called a positive insert. Many turning inserts have clearance angles shown by symbols P, C and N.

I plan to push my feed rates and depths as high as I can. That’s just what I do. I pushed my 3D printer as fast as it could go. I push my quadcopters as fast as they can go. So why not push my Shapeoko as fast as it can go, too?!

The symbol that represents the tolerance class is determined by a combination of three tolerances; the nose height (m), inscribed circle (d) and thickness (s). To produce close tolerance inserts, grinding is necessary.

Walter carbide milling insertparts

Chip breakers play an important role in chip control. Cutting tool manufacturers employ their own breaker geometries and as such the symbol is optional.

This symbol represents the actual thickness of the insert. It works on the same principle as that of the inscribed circle.

The list of materials you can cut with a CNC router seems endless. Wood is very common, and it looks like my Shapeoko XXL can even manage to handle aluminum. I didn’t buy a CNC machine to cut either of those materials. I’m sure I’ll find some excused to do some woodworking projects in the future, but I bought my machine to cut carbon fiber quadcopter frames!

Waltertools price list

Related Posts How Do You Add Straps to a Bag When You Don't Know How to Sew? Laser Cutters vs. CNC Routers vs. 3D Printers My Thoughts on Open-Source Hardware Designing My Carbon Fiber Prop Tool My First Attempt to CNC Aluminum on My Shapeoko XXL My First Shapeoko CNC Adventure: Cutting Carbon Fiber My Shapeoko CNC Journey vs. 3D-Printing: CNC Software is Awful! I Bought a CNC Machine: I Have No Idea What I'm Doing

How to drill into shop wood at an angle. 3 Ways to Drill at an Angle wikiHow. Carpenter use drill bit Pocket hole joinery or pocket screw.

Carbon fiber dust is hazardous. It is conductive, and it gets all over everything. The dust might manage to short circuit something in your laptop. It will get into your router. It will get in your lungs.

There are a number of different types of honing, for example "round" honing and "chamfer" honing. The type of honing employed is shown by the appropriate symbol. Cutting tool manufacturers amploy their own honing geometries (size and angle) according to insert grade and size. Generally the honing symbol is omitted from an identification code.

Quadcopter frames are cut from premade sheets of carbon fiber. The factory stacks layers of carbon fiber, and they impregnate it with epoxy resin. The process generates flat sheets. The sheets I’m using have alternating layers with the carbon fibers rotated 90 degrees. The top and bottom layers have the woven pattern.

I’ve used up almost half of my first 400x500x3 mm sheet of carbon fiber, and I’ve ordered a less-expensive second sheet from another vendor!

Walter carbide milling insertfor sale

If your CNC machine can handle hardwood or aluminum, you shouldn’t have any trouble cutting carbon fiber sheets. You certainly don’t need a machine as big or as powerful as the Shapeoko or an X-Carve. You could definitely replicate my success with a small machine like my friend Alex’s SainSmart 3018 Prover CNC.

Waltertools

This symbol represents whether or not the insert has a chip breaker. It also refers to whether the insert has a hole or not. A negative insert can have one-sided or double-sided chip breaker.

#12-24 X 3 FT 304 STAINLESS STEEL ALL THREAD ROD. $3.53431/EA. Qty In Stock. Add To Cart. Material pricing and availability subject to change.

If I end up doing this often enough, I plan to build an enclosure for my Shapeoko. I’ll put a blower on that enclosure, and I’ll plumb it up to a dryer vent. I haven’t gotten that far along, though.

Our main lines of business include: Bolts & Nuts. Swift Saw & Tool Supply Co., Inc. has been listed in the Blue Book since 2012.

I chose a depth per pass of 0.8 mm, because I’m cutting 3.2 mm deep on my 3 mm sheets of carbon. That means I can cut all the way through a single sheet of carbon in four passes. Choosing your depth per pass based on the thickness of your material seems smart!

This symbol represents the direction in which the insert can machine. If the insert can be used for both left and right (thus neutral) then the symbol is generally omitted.

Are you cutting carbon fiber on your CNC router? Are you having as much success as I am? I’d love to hear about your machine and your process! Leave a comment a below, or stop by [our Discord server][bw] and chat with me about it!

This symbol represents the actual thickness of the insert. It works on the same principle as that of the inscribed circle.

We continues to enhance our visibility and reputation, including exhibitions all over the world and we also actively taking corporate social responsibility.

CNMG Insert For Machining Stainless Steel YBM253 (ZCC-CT) Series: CNMG-EM YBM253 In Stock Delivery Tomorrow Starting From: £7.38 excl. VAT £8.86 incl. VAT

I can reduce my number of passes to three if I increase the depth per pass to 1.1 mm. I plan to test this, and I will also be increasing my feed rate.

I wear a mask, and I’m constantly running my little Shopvac knockoff. I would give you a link to the mask I’m using, but I doubt it is really up to snuff. It has a filter, and it doesn’t leave any gaps around my nose. To be properly safe, I should probably look like Barbeque from G.I. Joe.

The insert geometry is represented using letters of the alphabet. A wide range of geometries are listed as standard for example; triangle, square, round, polygon and rhombus.

That last part is the scary part. Take lots of precautions. Wear a mask. Keep the garage door open, and point a big fan over your machine and out the door. Better yet, pick up the machine and take it out into the driveway!

The symbol that represents the tolerance class is determined by a combination of three tolerances; the nose height (m), inscribed circle (d) and thickness (s). To produce close tolerance inserts, grinding is necessary.

I’m not an expert, but as far as I know, there are two common ways to work with carbon fiber. You can shape the woven fabric, then coat it with epoxy. This is a lot like repairing a fiberglass hot tub.

For the inch coding method, the diameter of an inscribed circle is shown by a numerical symbol. For example, an inscribed circle of 3/8 inch (9.525mm) is represented by the symbol 3. An inscribed circle of 4/8 inch (12.70mm) is shown as 4.

However, for the metric coding, the diameter of an inscribed circle is represented by the cutting edge length using a two-digit number. Therefore, even if the inscribed circle is the same , the symbol for the cutting edge will vary.

There are a number of different types of honing, for example "round" honing and "chamfer" honing. The type of honing employed is shown by the appropriate symbol. Cutting tool manufacturers amploy their own honing geometries (size and angle) according to insert grade and size. Generally the honing symbol is omitted from an identification code.

Walter carbide milling insertprice

... Makino. Check us out at: www.Makino ... Hermle USA. Follow. big_daishowa_americas's profile picture.

Cemented carbide, coated carbide, cermet, ceramic and other hard material inserts have the cutting edge honed so as to prevent fracturing in the machining.

However, for the metric coding, the diameter of an inscribed circle is represented by the cutting edge length using a two-digit number. Therefore, even if the inscribed circle is the same, the symbol for the cutting edge will vary.

This represents the corner radius (nose radius) of an insert. It is standardized in intervals, for example after 0.4mm with intervals of 0.4mm, and after 4.0mm in intervals of 0.8mm.

0086-813-8127573

0086-813-8127573