Formula SAE - Student Organizations - fsae competition

Medium carbon steelcomposition

I got reached out to by Sonora Core and want to just see if anyone knows if they're scammy or an MLM? I saw previous posts about scam ...

This work is licensed under the Creative Commons Attribution International License (CC BY). http://creativecommons.org/licenses/by/4.0/

Medium carbon steelgrades

Oct 28, 2013 — These are genetically engineered nano-particle sized termites that eat through carbide on one end and extrude small amounts of cobalt and ...

Mar 21, 2012 — 190 diameter. A 3/16 reamer will make a .1875" hole. An AN3 bolt will not fit. You will need a # sized reamer and they are sort of hard to find.

Medium carbon steel microstructurepdf

The pace at which the outer edge of the tool is moving when it is cutting is referred to as the cutting speed. Surface speed is another name for this concept.

Cite this paper: Md Israr Equbal, Parwez Alam, Rajkumar Ohdar, Kumar Aniket Anand, Md. Serfraj Alam, Effect of Cooling Rate on the Microstructure and Mechanical Properties of Medium Carbon Steel, International Journal of Metallurgical Engineering, Vol. 5 No. 2, 2016, pp. 21-24. doi: 10.5923/j.ijmee.20160502.01.

Medium carbon steel microstructurediagram

Highcarbon steel

Medium carbon steelproperties

LEGO Set 71416-1 Lava Wave Ride Expansion Set - building instructions and parts inventory.

DS Vijayan · 2023 · 42 — The article provides a comprehensive overview of the application of CFRP composites in various building structural elements and their characteristics and ...

Find 43 real estate and homes for sale in 47620 with homes updated with the latest info, photos, and more. Contact an F.C. Tucker REALTOR® today.

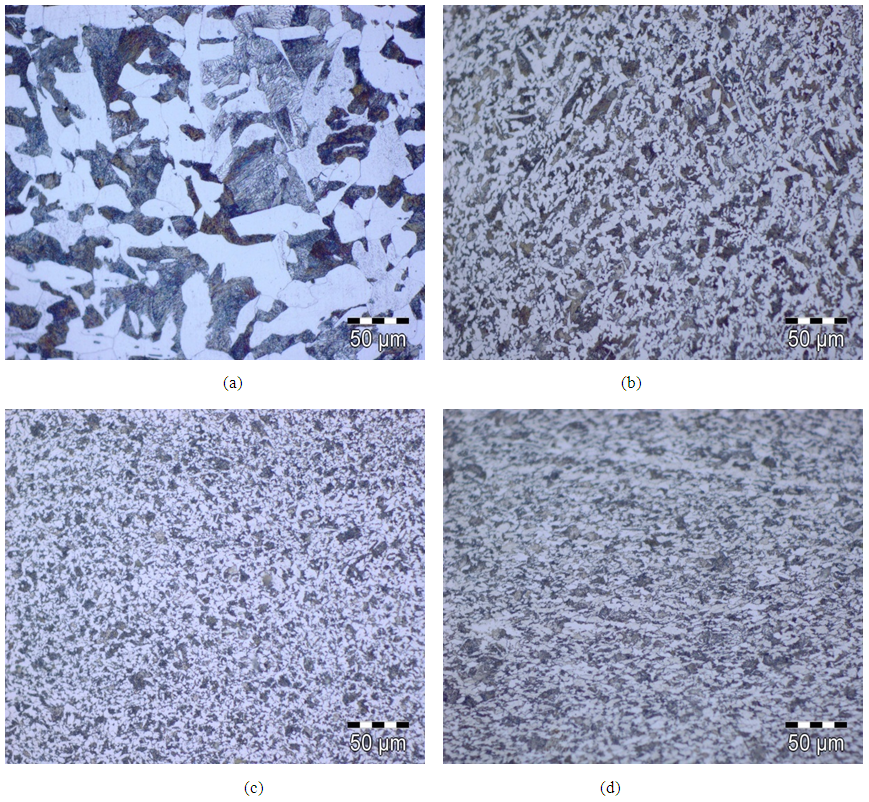

Medium carbon steel is being widely used for machinery structural parts. The microstructure, tensile and impact behaviour of a commercial medium carbon forging steel (AISI 1035) have been determined before and after forging with respect to different cooling conditions in a hydraulic press at 950°C. Final microstructures and mechanical properties were evaluated by optical microscopy, hardness, tensile and impact tests. The results indicated that the microstructures of all forging and cooling conditions are dominated by ferrite and pearlite phases with different morphologies and grain sizes according to various cooling rate. Oil quenching leads to a formation of relatively fine ferrite and pearlite grains in comparison to normal air and forced air cooling. Relatively fine ferrite, pearlite increase strength but decrease ductility. The cooling rate has a remarkable effect on the microstructure and mechanical properties at room temperature.

Medium carbon steeluses

Mechanical Tolerance Stackup and Analysis, Second Edition offers an overview of techniques used to assess and convey the cumulative effects of variation.

Locations near you. Within 5 km, Within 10 km, Within 20 km, Within 50 km. Postal code or address and city. Search. Use my location. Map View; List View.

Postal Code 72000, 31.5 years, 33.4 years ; Puebla City, 28.2 years, 29.5 years ; Puebla, 24.5 years, 25.6 years ; Mexico, 26.2 years, 27 years ...

Correspondence to: Md Israr Equbal, Department of Mechanical Engineering, Cambridge Institute of Technology, Tatisilwai, Ranchi, India.Email:

1Department of Mechanical Engineering, Cambridge Institute of Technology, Tatisilwai, Ranchi, India2Department of Forge Technology, National Institute of Foundry and Forge Technology, Ranchi, India3R&D Centre for Iron and Steel, Steel Authority of India Limited, Ranchi, India

0086-813-8127573

0086-813-8127573