Four Seasons 20168 Blower Motor Resistor - 20168

I am having some trouble finding the sweet spot on the clamp nut on the base. I have been running it on the loose site cause I was having trouble with it failing to raise and z getting lost. I have sprayed it with graphite as a dry lube, not sure what the go to solution is.

What isclimbmilling

it’s more a matter of towards and away from the motors than it is clockwise vs counter-clockwise (one would work better on the left, the other on the right.

Thanks for the link, I always try to run a climb cut when CNC’n. And the Maslow seems o work better in climb (except for the dreaded corners).

Climb cut vs conventional cutpros and cons

This makes sense, I was noticing the direction of travel relative to motor has a large impact in the lower corners. However, I am also noticing a pretty sizable offset when cutting one way versus the other. So, it seems I would have to dial in an offset to the geometry to adjust for the smaller parts when cutting conventional.

Climb vs conventionalmilling aluminum

Welcome! I have not read discussions about this in the forum. Thanks for bringing it up. One aspect of the Maslow that can’t be compared to horizontal cnc is, that we have issues in the down outer corners on down cuts. What I will try if I would cut on a full sheet is, to have the most left part cut clockwise, so the router moves up on the outer cut. On the right side I would choose counter clockwise, so the router moves up on the outer cut. No idea if that helps, but it’s worth a try I guess.

Generally, climb cutting is preferred for milling, as it produces a better surface finish. This CNC Cookbook article covers the topic pretty well:

Yeah, conventional in the lower left and climb in the lower right seems to work best. Wish there was a setting to make it do both if you get within a certain radius of the bottom corners. All in the G-code, I know…

Climb cut vs conventional cutreddit

This has been my experience as well. I had one cut set up to do a final pass in the opposite direction. I’m not sure how, but somehow I made that happen with Easel. It worked really well. The backwards pass cleaned up any slight roughness.

it’s more a matter of towards and away from the motors than it is clockwise vs counter-clockwise (one would work better on the left, the other on the right.

Climb cut vs conventional cutwoodworking

I am cutting parts in both climb and conventional direction and finding some things as I would expect, the conventional cuts are producing smaller parts and the climbs larger one. I am wondering what people are finding are the other pros/cons to these cut directions. I feel more confident doing my outer profiles with climb cut as the tendency will be to fail in the waste direction… but, I may be making other things less good. (i.e. rounded over sharp corners, oblong circles.) I am interested what the community has found.

Climb vs conventionalmilling surface finish

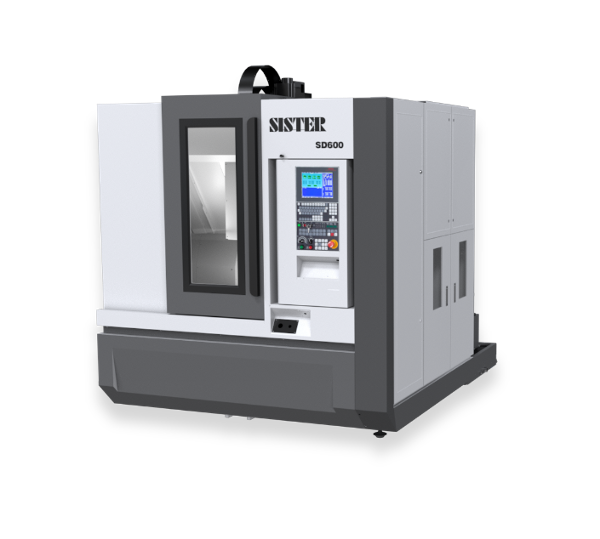

Not only that, SD600G won The National Brand Yusan Award in 2020, which means that the quality of our graphite machining center is performance and high quality for the customer to produce a wide selection of parts for industrial applications.

In addition, The SD600G has a fully enclosed splash guard that completely seals graphite dust inside to prevent dust leak out. Besides sealing graphite dust, dry machining of carbon fiber and brittle hard power metal is also possible.Moreover, the low tooling wear and corner high acceleration deceleration make the graphite machining center more applicable to the needs of processors in today's market.

SD600G graphite machine center provides high-speed and precise graphite machining with a built-in spindle and designed plus-minus pressure system & excellent dust proof structure that prevents the inflow of graphite.

When should you use Climb vs Conventional Milling? What's the difference? CNC'ers almost always use Climb, but there are cases where it's detrimental. Learn when to use Climb (Down) vs Conventional (Up) Milling.

0086-813-8127573

0086-813-8127573