Fowey Rocks to Alligator Reef | NOAA Chart 11462 - 11462

Cobalt steelcomposition

Co has few, but highly specialized, uses in alloy steels. Its behavior is similar to Ni, in that it forms a complete series of solid solutions with iron at elevated temperatures and is also extremely soluble in ferrite. It is a potent ferrite strengthener; this solid solution strengthening persists to quite high temperatures, and hence Co is used in several grades of high speed tool steels, among others.

Magnetic steels containing from 9 % to 40 % Co have been used for compass needles, hysteresis motors and electrical instrumentation.

One unique new nail market is the result of the increase in building restoration and preservation efforts throughout the country. One nail factory in Massachusetts makes old-fashioned cut nails. They estimate that 20% of their work is in producing a variety of these nails for use in authentic building restoration projects.

In order of decreasing tonnage usage, primary applications of Co are in non-ferrous (super)alloys, magnets, high speed tool steels, ultrahigh strength alloy steels, abrasion-resistant cemented carbides for cutting tools and stainless steels.

The length of a nail is measured in a unit called the penny. This term comes from the use of nails in England in the late 1700s when it referred to the price of one hundred nails of that size. For example, a "ten penny nail" would have cost ten pennies per hundred. The symbol for penny is "d," as in 10d. This designation is believed to go back to the time of the Roman Empire when a similar form of measurement for hand-forged nails involved a common Roman coin known as the denarius. Today the term penny only defines the length of a nail and has nothing to do with the price. The shortest nail is 2d which is 1 inch (2.5 cm) long. A 10d nail is 3 inches (7.6 cm) long, and a 16d nail is 3.5 inches (8.9 cm) long. Between 2d and 10d the nail length increases 0.25 inch (0.64 cm) for each penny designation. Beyond 10d there is no logical progression to the lengths and designations.

Cobalt steelknife

In the production of co bearing alloy steels, additions of Co during the steel making is made in the form of Co metal which is supplied to steel producers in the form of briquettes, granules, and broken electrolytic cathodes. Content of Co in these additive agents is usually in the range of 98 % to 99.9 %.

Co is not a popular element which is commonly added to alloy steels. It does have some effects but these can also be achieved with other alloying elements such as molybdenum (Mo), and nickel (Ni) etc. at lower costs and mostly with better results. Due to this factor, Co does not find enough use in high tonnage low alloy steel production. However it does have some niche markets in steel.

Co is unique among alloying constituents in steel in that it is the only element that has negative effect on the hardenability of steel by accelerating the decomposition of austenite. It has a tendency to graphitization and is a very expensive component, hence it is not used as an alloying addition in normal steels. It is never used in the standard heat treatable steels. Co is, however, a constituent of maraging and 9Ni-4Co ultrahigh strength steels but here, its presence is overcome—from a hardenability standpoint—by the remaining alloying constituents.

M42steelcomposition

Nails are divided into three broad categories based on their length. In general nails under 1 inch (2.5 cm) in length are called tacks or brads. Nails 1-4 inches (2.5-10.2 cm) in length are called nails, while those over 4 inches (10.2 cm) are some-times called spikes. These categories are roughly defined, and there is considerable crossover between them.

Through the ispatguru.com website I share my knowledge and experience gained through my association with the steel industry for over 54 years.

Most of the 300 different types of nails produced in the United States today require no new design work. Once a nail has been designed, forming dies and processes are developed for its manufacture, and the nail is produced in quantity.

Co bearing high speed steels have a somewhat greater tendency to decarburization and are more sensitive to cracking when exposed to abrupt temperature changes. They are also somewhat more brittle than non Co grades. However, their increasing popularity is due to their excellent red hardness property.

Steel cobaltuses

Nails may have been used in Mesopotamia as early as 3500 B.C. and were probably made of copper or bronze. Later, iron was used to make nails. Early nails were shaped, or forged, with hammers. They were usually made one at a time, and were consequently scarce and expensive. By the 1500s a machine was developed which produced long, flattened strips of iron, called nail rods. These strips could then be cut into lengths, pointed, and headed. Nails were so valuable in the early American settlements that in 1646 the Virginia legislature had to pass a measure to prevent colonists from burning down their old houses to reclaim the nails when they moved. Two early nail-making machines were patented by Ezekial Reed of the United States in 1786 and Thomas Clifford of England in 1790. These machines cut tapered pieces from flat iron sheet, then flattened the head. In rural areas, black-smiths continued to make nails from wrought iron right into the 20th century. The first machine to make nails from metal wire was introduced in the United States in about 1850, and this technique is now used to make most of the nails today.

The Co matrix has a high-work hardening sensitivity, which combines with the carbide fraction and allows to achieve excellent wear resistance associated with a high degree of corrosion resistance.

Likewise, hot work die steels may contain about 0.5 % Co for better wear resistance and higher hot hardness. The chromium-bearing grades contains up to 4.25 % Co for this reason.

Maraging steels containing Co have found many uses where their strength coupled with workability have got them the application over possibly stronger materials. These ultrahigh strength alloy steels are commonly heat treated to yield strengths approaching 2070 MPa and have excellent toughness as well. Their primary application is in aircraft and aerospace and military industries. Typical applications are landing gears, arrestor hooks, torque shafts, rocket motor casings, gun barrels, bolts, fasteners, extrusion arms etc.

Co becomes highly radioactive when exposed to the intense radiation of nuclear reactors, and as a result, any stainless steel that is in nuclear service will have a restriction in the Co content which is usually around 0.2 % maximum.

Nails are essential to the construction of wood-framed buildings. This, however, was not always the case. Until the late 18th century, Americans built wooden buildings using heavy timber frames. At places where these massive timbers had to hold together, one end of a post or beam would be cut down to form a tongue ("tenon") and fitted into a hole ("mortise") cut in the adjoining beam. Additional strength could be added by driving wooden pegs through auger holes in the joined timbers. The skill and labor involved in such construction was considerable; carpenters had to be highly skilled individuals and, as such, commanded high prices in colonial America.

As new building materials become available, nail manufacturers work to develop new nails. There are special nails for tile roofing, hardwood flooring, shingles, rain gutters, wall board, sheet metal, and concrete. Some new nails are designed to be driven by air-powered nail guns rather than by a hammer. There have even been new nails designed for specific applications in the aerospace industry.

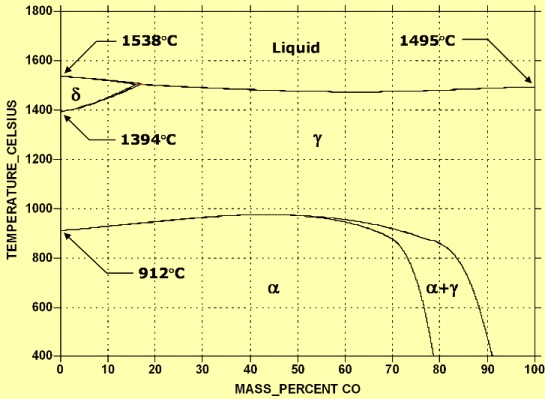

Solubility of Co in the ? iron is up to 75 % while in the ? iron it is unlimited. Co is the only one alloying element that increases the critical cooling rate of steel and accelerates pearlitic transformation thus reducing hardenability.

Co raises the A3 temperature in tool steels, thus calling for somewhat higher austenitizing temperatures. This is beneficial in that it forces a greater degree of dissolution of the complex carbides these materials contain. Co does form a carbide of the Fe3C type, but this compound does not contribute to secondary hardening.

The addition of Co to cold work die steels (as in steels with 3 % Co) increases hardness and promotes greater wear resistance than grades where it is not used.

Most nails have a broad, circular head. Finishing nails have a narrow, tapered head which allows them to be countersunk below the surface of the material and covered over to produce a smooth finish. Upholstery nails have decorative heads. Double-headed nails are used to fasten wood forms used in concrete pouring. The nail is driven in up to the first head, leaving the second head protruding. The protruding head allows the nails to be easily removed and the forms quickly dismantled once the concrete has hardened.

Until the end of the 18th century, nails were imported from England or made by local blacksmiths. The smithy, or often his apprentice, took a piece of bar iron maybe 5 feet long and 0.06-0.25 inch in diameter. Holding one end he heated the other, laid it on the anvil and, using the flat face of his hammer, tapered all four sides to about an inch from the end. He then used the peen, or sharpened end of his hammer, or a hardy, a wedge-shaped attachment to his anvil, to cut a notch in the rod. He thrust the sharpened end of the rod into a tapered hole in his anvil and snapped off the short nail. Then he flattened the end of the nail with four or five quick strikes of the hammer and popped it out of the anvil hole with a quick, upward strike at the point.

The metallurgical behavior of Co is similar to that of Ni and hence oxide of Co is readily reduced in all but the most oxidizing steel baths and may be added to the electric arc furnace or the AOD(argon oxygen decarburization) furnace. More common practice in tool and alloy steel production, however, is to melt down a high scrap charge and then adjust the final Co content with the addition of Co metal. Vacuum melting is also employed for the production of steels with Co additions.

Vila, Bob. This Old House Guide to Building and Remodeling Materials. Warner Books, 1986.

Co increases hardness and allows for higher quenching temperatures during heat treatment. It intensifies the individual effects of other elements in steels with complex compositions.

Cobalt steelproperties

A nail consists of a metal rod or shank, pointed at one end and usually having a formed head at the other, that can be hammered into pieces of wood or other materials to fasten them together. A nail is usually made of steel, although it can be made of aluminum, brass, or many other metals. The surface can be coated or plated to improve its corrosion resistance, gripping strength, or decorative appearance. The head, shank, and point may have several shapes based on the intended function of the nail. Of the nearly 300 types of nails made in the United States today, most are used in residential housing construction. The average wood frame house uses between 20,000 and 30,000 nails of various types and sizes.

Cobalt (Co) (atomic number 27 and atomic weight 58.94) has density of 8.85 gm/cc. Melting point of Co is 1493 deg C and boiling point is 3100 deg C. At temperatures below 417 deg C cobalt exhibits a hexagonal close packed structure. Between 417 deg C and its melting point of 1493 deg C, Co has a face centered cubic (fcc) structure. Co is a magnetic metal with a curie temperature of 1121 deg C.

Co is used in a series of magnetic steels, It is an important constituent of the 18 % Ni maraging steels and several other ultrahigh strength steels and is added to one grade of austenitic stainless steel.

This massive, mid-19th-centvry nail cutting machine used a shearing action to cut nails from bar iron. (From the collections of Henry Ford Museum & Green-field Village.)

The demand for specialty nails, on the other hand, is expected to continue to grow and be profitable. New building materials, such as composite wood-fiber and cement-based siding and roofing, require new specialty nails. New corrosion-resistant coatings for nails are also being developed.

Steel cobaltvssteel

Most nails are made from coils of metal wire. The wire is fed into a nail-making machine which can produce up to 700 nails per minute. The nails may then be further twisted or formed, cleaned, finished, and packaged.

Loveday Jr., Amos J. The Rise and Decline of the American Cut Nail Industry. Greenwood Press, 1993.

Johnson, Duane. "Nails Get a Better Grip." The Family Handyman, September 1994, p. 16.

During manufacture, nails must also meet certain specifications regarding dimensions and properties. These are achieved using a method known as statistical process control, which periodically samples the dimensions and properties of the nails being produced and evaluates any changes through statistical analysis techniques.

Cobalt steelhardness

The effects of Co additions on the mechanical properties and strengthening mechanisms of martensitic precipitation strengthening stainless steels, whose composition is 0.005 % C/12 % Cr/5 % Mo/1.5 % Ni with Co levels of 9 %, 12 %, 15 %, 18 %, and 21 %, shows that hardness, yield strength and ultimate tensile strength increases as the Co content increases, while the charpy impact energy decreases as tempering temperature increases

The presence of Co in the steel improves its durability and hardness at higher temperatures, reduces the fall in hardness of austenite and ferrite under the influence of temperature increase, and therefore is used as a supplement to some grades of high speed steels and tool steels. It is also a component of creep resistant steels.

Between 1790 and 1830, several mechanical devices were developed in Europe and the United States to speed the production and lower the cost of nails. It is not entirely coincidental, therefore, that the balloon-framed house, which relied on two-by-fours held together by nails, was invented in the early 1830s in Chicago. The balloon-frame system required much less skill and labor in carpentry and made use of mass-produced nails.

Most nails are made of steel. Aluminum, copper, brass, bronze, stainless steel, nickel silver, monel, zinc, and iron are also used. Galvanized nails are coated with zinc to give them added corrosion resistance. Blued steel nails are subjected to a flame to give them a bluish oxide finish that provides a certain amount of corrosion resistance. So-called cement-coated nails are actually coated with a plastic resin to improve their grip. Some brads are given a colored enamel coating to blend in with the color of the material they are fastening.

The demand for mass-produced commodity nails is dependent on the fluctuations in the housing market, which varies with the economy. Demand for these nails is also subject to competition from foreign manufacturers, further reducing profits.

Scrap of super alloys normally contains high percentage of Ni and hence is not used for the production of tool steels. However this scrap can be used for the production of maraging and ultrahigh strength steels.

The most typical nail point is a four-sided tapered cut called a diamond point. Other nails may have a blunter point to prevent splitting certain woods. Chisel points, barbed points, needle points, and many others are sometimes used on specialty nails.

Co is a valuable alloying element for high speed tool steels. It has the effect of raising to softening temperature of ferrite so that tools made from Co bearing alloy steel can operate at high temperatures, maintaining their cutting capacity.

Co is not a carbide former. However addition of Co to alloy steels allows for higher attainable hardness and higher red hot hardness.

Steel cobaltfor sale

Rolling and hot working High speed tool steels containing Co are treated in a similar way as Co free alloy steels. Since the composition of these highly alloyed steels is quite complex, these steels are susceptible to heavy segregation. Hence these steels ordinarily require massive amounts of hot reduction to break up the cast structures. These days with the development of powder processes in combination with hot isostatic pressing (HIP process) techniques, these processes have become more preferred route for the production of high speed tool steel containing Co.

The shank is usually designed to be round and smooth. Shanks with serrations, annular grooves, spiral flutes, or helical threads are used when a stronger, more permanent grip is required. Thermoplastic coatings may also be added to the shaft. These coatings heat up through friction while the nail is being driven, then quickly cool and set to lock the nail in place. The diameter of the shank is determined by the type of nail. Most nails, called common nails, have a relatively large diameter. Box nails, originally used to make thin-walled boxes, have a smaller diameter shank than common nails. Finishing nails have a very small diameter shank in order to make the smallest hole possible.

Cobalt is added to high speed steels to improve hot hardness. It is found in both Mo and tungsten (W) grades of tool steels.

Raw materials must meet certain standards for chemical composition, yield strength, hardness, corrosion resistance and other properties. These are usually certified by the company supplying the wire, and may be independently checked by the nail manufacturer.

0086-813-8127573

0086-813-8127573