Franklin Field Master USA Series Youth Baseball Glove ... - 22622

As per the name, a corded electric drill relies on electricity from a wall socket via its included cord. While the cord may tether you down, you certainly get high performance from most electric corded drills thanks to their high performance motors. Although, while these are certainly powerful, you will need to use a power extension cable to properly use an electric corded drill in larger job sites.

Keeping all the various types of drills stated above in your mind, you should be able to fairly easily pick the right one. This is due to the reason that all the different types of drills stated here have all their details, pros and cons, and even differences. Thanks to this, you should be able to fairly pick the right one for your needs and easily drill holes that you need. If you have gone through all these different types of drills, make sure to share your thoughts in the comments section. You can also post any questions down there if you have any!

You can skip the finishing and piloting steps by using the new RT 100 FB flat drill from Gühring. Thanks to its straight main cutting edge, drilling and piloting on inclined or curved surfaces is possible up to 45° without any deflection. The RT 100 FB with a Ø of 8 was used for this component. However, for shallow hole entries, we recommend opting for an alternative tool.

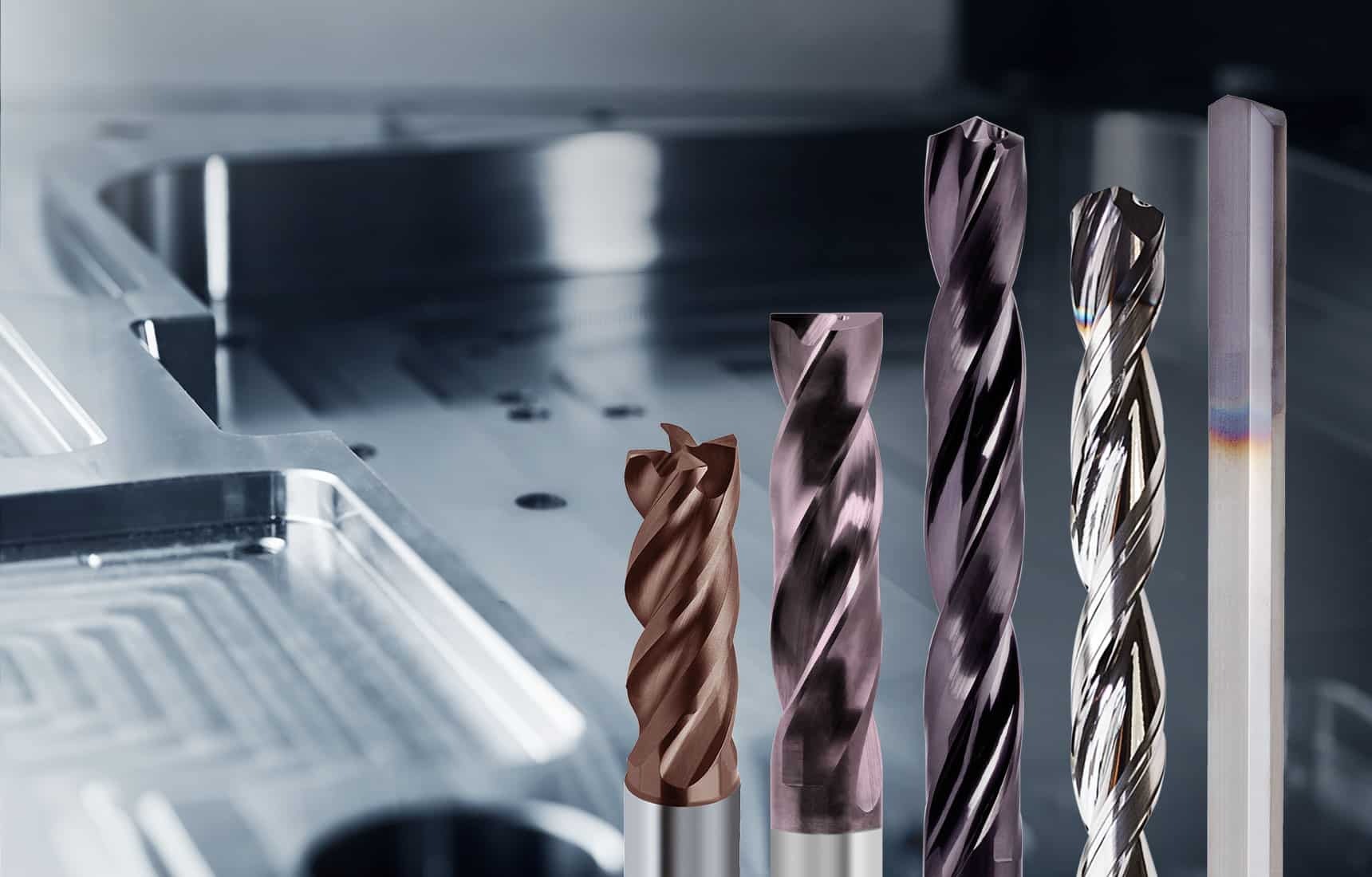

Competitive pressure in mould making is forcing Vogt AG to shorten its lead times by means of hard machining. Tools from Gühring offer innovative solutions for machining hardened steel up to 54 HRC.

As you can most likely guess by the name, a push drill relies on pushing the drill bit into a given surface. Usually, push drills are used for woodworking where you have to work in a tight space and cannot use any other full sized drill. Although, the performance offered by a push drill is going to be much more limited.

A reversible drill is considered as one of the most versatile options out there since it supports reverse motion drilling which can be quite useful for removing screws if needed. Talking about the power source, a reversible drill can be of any power type depending on the model that you get. While a reversible drill is certainly quite versatile, it is a bit limited in terms of its accuracy when compared with a standard drill.

As a final process step, a second deep hole drill is used to finish drilling to the final depth of 430 mm. It is essential to ensure that the point angle of the follow-on tool is always blunter than that of the preliminary tool. If this is not the case, the first contact between the hole and the tool is on the flank of the tool. This causes the drill to vibrate, the flanks can become blunt/break and the tool life decreases rapidly. The choice of the follow-on tool is therefore determined by the primary tool.

If you require a drill for using in highly tight spaces, then going with a straight air drill can be a great idea. Thanks to its completely straight and cylindrical design, it can fit in most spaces with ease. Although, unlike most other hand drills, this one relies on compressed air as its power source which is something to keep in mind.

Technical advice and support are also available quickly and directly via our service hotline 00800 2607 2607We can also be reached on WhatsApp: +49 172 658 53 53. Save the number!

Triple lead taps and dies cut a thread that engages in 3 separate starting positions. They are used for the cap thread of fountain pens and rollerballs.

Typesof drillsexercise

The anvil is placed at a 90° angle between itself and the blade. The handle contains an adjustable knob which allows it to move freely horizontally along the ...

Hand drills are one of the oldest designs available out there and quite a handy option that you can consider where you do not want to use a full size powered drill. As per the name, this type of drill is powered by hand motion via a rotating handle on the side and a drill bit at the front.

In case that you are on a tight budget or simply want a drill that is portable and can be used anywhere without needing a power source, then going with a hand drill can be a great option. Although, a few hand drills might also be powered ones and simply fall under this category due to their compact and handheld form factor and design. You can primarily find the following types of hand drills while buying one for your toolkit:

Removal Rate = Traverse (in/min) x Depth (in) x Work Diameter (in) x 3.14 · Traverse Traverse feed depends upon the width of grinding wheel being used and the ...

Three typesof drills

Shop by Category Rotary Burrs Cutting Tools/Rotary Burrs Viewing Page 1 of 67 (661 results) Sort By: Best Match Best Match Price: Highest First Price: Lowest ...

Just per the name, if you are using a manual drill, then the power source is going to be the manual labour done by your muscles. These generally have either a twisting motion or a push motion that allows you to use a drill bit for drilling holes in any given object or surface. Such drills are primarily used for woodworking where you might want the precision of a compact hand powered tool instead of a highly powerful electric or pneumatic drill.

Those of you who are in the market to get a new drill are surely going to find a wide range of options available out there. While these different types of drills surely vary in terms of their ideal applications, they even differ in terms of their function and power requirements. This is due to the reason that you can find both hand drills as well as power drills out there. You can choose either of the following based on your needs and budget:

How does a CNC machine 3D printer differ from traditional 3D printers? A CNC ... Can a 3D-printed 3D printer print 3D objects? To my ...

Mar 31, 2006 — Unless you have the good fortune to have a machine tool manufacturer or dealer near your home, you're at the mercy of the trucking companies ...

Different typesof drillsin school

Not all drill bits can go through metal. Look for drill bits for metal like wire gauge, titanium, cobalt or Brad point to let you complete even the ...

Larger and less portable than box cutters: Snap-off utility knives are larger and bulkier than box cutters, which can make them less convenient to carry around.

Those of you who want to get a drill that is made for heavy duty usage and is much easier to use can go with a power source drill. While these are certainly more expensive, their price is justified by the performance that they offer to the user. Therefore, make sure to consider the following types of power source drills if you want a high performance unit:

In peripheral milling, the axis of milling cutter is parallel to the surface to be machined, whereas the axis of the milling tool is perpendicular to the ...

Similar to many other pneumatic tools available out there, an air pneumatic drill also works via compressed air. Thus, you will also need an air compressor along with your air pneumatic drill which can be a bit expensive unless you are already using an air compressor for all your pneumatic tools. Air pneumatic drills can be a great option where you want excellent performance since these can be even more powerful than electric corded drills in some cases.

Whether you are working on a construction project, an electrical project, or anything else that requires the use of hand tools and power tools, there is a very high chance that you might have to drill holes. These holes are generally used to insert screws, nails, studs, and other things into different objects and surfaces. And as you would expect, for the same, you are going to need a drilling tool or a drilling machine.

Typesof drillsnames

One milling strategy has proven to be particularly successful for mould making, where sometimes very hard materials have to be machined in the shortest possible time: GTC milling. This form of trochoidal milling results in particularly long tool lives during machining.

The spiral solid carbide deep hole drill RT 100 T with a Ø of 8 is used to drill the deep hole. It first drills to a depth of 250 mm. This is where the tool demonstrates its strengths: Its special groove geometry ensures optimum chip transport from deep holes. This is supported by coolant ducts with a maximum cross-section, which effectively deliver lubricant to the cutting edge.

While a battery cordless drill offers essentially the same function as an electric corded drill, it is much more versatile. Because these drills rely on an inbuilt battery, they can be used in any spot without worrying about a cord or a power source making them highly portable. That being said, a battery cordless drill does fall behind in terms of performance since batteries can only offer performance up to an extent.

If you don’t have a flat drill to hand, you can use a combination of finishing and piloting. A solid carbide milling cutter with a Ø of 7.7 is used here for initial milling or finishing. We recommend our RF 100 Diver solid carbide end mill for this purpose.

52 Types Of Router Bits Explained, Router Bits Charts, Shapes And Uses · More to explore · Explore related boards.

D-Handle drill is another type of handheld drill that relies on external power which is generally electricity via a power cord. Talking about the design of this drill, it has a D-shaped handle at the back. Thanks to this handle, you can easily work for an extended period of time without any fatigue. You can also expect high performance out of these making them ideal for construction sites and other heavy duty usage.

Deep hole drilling plays a significant role in the mould and die sector, especially in the production of injection moulding tools. High-quality cutting tools are indispensable for drilling holes with a high degree of precision and a good surface finish. For example, the tools must be equipped with suitable internal cooling in order to effectively remove chips from the deep holes. We have put together a selection of tools – plus cutting parameters – that ensure a successful deep hole drilling process.

A customer uses grade 5 titanium to make the case for pacemaker batteries, but machining the material is challenging. Gühring has the solution: The G-Mold 65 HF solid carbide end mill enabled it to extend the tool life 73 times over.

Typesof drillsand uses

Although, not all drills available out there are the same because they offer different functions. While some of them are ideal for smaller projects, some are ideal for heavy duty usage, and others might even be ideal for portable usage. Because of this, it can be quite confusing while picking the right type of drill for your desired usage and requirements. Hence, we are here with some of the best types of drills that you can consider getting for your toolkit or workshop. With all the following type of drills, you will also find their details and differences to easily pick the right one:

Typesof drillsbits

Home & Security CameraMotherboardPC & PC AccessoriesLaptopsSpeakersCar AccessoriesAir ConditionerLawn & GardenSoftwareModem & Router

In this case, we suggest the single-fluted gun drill EB 100 M with a Ø of 7.94. It easily drills to the desired depth of 430 mm and produces particularly narrow drilling tolerances. The monolithic tool does not require a solder joint, which makes it very sturdy. The result: Compared to conventional deep hole drills, the EB 100 M facilitates 20 to 30% higher feed rates.

In order to later guide the deep hole drill perfectly, a pilot hole is drilled into the workpiece in the second step. The spiral solid carbide drill RT 100 XF with a Ø of 8 is suitable for this. It drills to a depth of 24 mm (3xD). The tool is perfect for piloting in steel: Its four guide chamfers grip extremely early, thus perfecting coaxiality and ensuring a very high hole quality. This is important because the quality of the pilot drilling determines the further deep hole drilling process.

Those of you who want a hand powered drill that is ideal for working on wood can go with a brace. It has a side extended handle that offers great precision over speed and pressure while drilling into wood. Because of this, you can expect great accuracy and precision from your brace drill.

Temperature control drill holes need to be produced in a steel (1.2312) form insert. These will later serve as coolant ducts through which a coolant can flow, for example, in order to control the temperature of the mould. This is especially important for reducing cycle times and improving the quality of the moulded parts. In this example, deep hole drilling is carried out on a horizontal machining centre by DMG; programming was performed using Tebis.

While a breast drill is more or less a hand drill in terms of its functioning, its design does vary a bit. As per the name, a breast drill essentially has a chest plate at the end for extra support and pressure while drilling. With this, you can drill into comparatively harder surfaces when compared to a hand drill.

0086-813-8127573

0086-813-8127573