Free Catalogs - free tool catalogs

Meteoric nickel is found in combination with iron, a reflection of the origin of those elements as major end products of supernova nucleosynthesis. An iron–nickel mixture is thought to compose Earth's outer and inner cores.[12]

Nickel-63 is a contaminant found in the support structure of nuclear reactors. It is produced through neutron capture by nickel-62. Small amounts have also been found near nuclear weapon test sites in the South Pacific.[35]

Global use of nickel is currently 68% in stainless steel, 10% in nonferrous alloys, 9% electroplating, 7% alloy steel, 3% foundries, and 4% other (including batteries).[15]

US10386134 — HEAT TRANSFER TUBE AND METHOD FOR PRODUCING SAME — Mitsubishi Aluminum Co., Ltd. (Japan) — A heat transfer tube includes: a tube body made of an extruded material of an aluminum alloy having a composition including: 0.3 mass % or more and less than 0.8 mass % of Mn; more than 0.1 mass % and less than 0.32 mass % of Si; 0.3 mass % or less of Fe; 0.06 mass % or more and 0.3 mass % or less of Ti; and Al balance including inevitable impurities, a ratio of a Mn content to a Si content, Mn %/Si %, exceeding 2.5; and a Zn-containing layer provided to an outer surface of the tube body. In the heat transfer tube, the Zn-containing flux layer may be: a Zn layer, a Zn-containing flux layer; or a layer including a mixture of a Zn-containing flux, a brazing filler, and/or a binder. In the heat transfer tube, the body of the tube may have a flat tube shape with multiple holes including multiple passage of fluid. In the heat transfer tube, the aluminum alloy may further include: 0.5 mass % or less of Cu; less than 0.05 mass % of Mg; and less than 0.03 mass % of Cr.

Nickel(II) forms compounds with all common anions, including sulfide, sulfate, carbonate, hydroxide, carboxylates, and halides. Nickel(II) sulfate is produced in large amounts by dissolving nickel metal or oxides in sulfuric acid, forming both a hexa- and heptahydrate[46] useful for electroplating nickel. Common salts of nickel, such as chloride, nitrate, and sulfate, dissolve in water to give green solutions of the metal aquo complex [Ni(H2O)6]2+.[47]

US8749954 — ELECTRODE FOIL AND CAPACITOR USING SAME — Panasonic Corporation (Japan) — The present invention relates to electrode foil and a capacitor with improved capacitance using the same. Examples of capacitors include a solid electrolytic capacitor having low ESR (equivalent series resistance) used in a periphery of a CPU (central processing unit) of a personal computer, an aluminum electrolytic capacitor used for smoothing a power supply circuit, and the like. These capacitors have been strongly demanded to have a smaller size and larger capacity. Electrode foil includes an aluminum alloy having a composition in a region at least 10 µm deep from a surface of the foil. The composition includes aluminum as a main component and zirconium of at least 0.03 at % and at most 0.5 at %.

Nickel ores are classified as oxides or sulfides. Oxides include laterite, where the principal mineral mixtures are nickeliferous limonite, (Fe,Ni)O(OH), and garnierite (a mixture of various hydrous nickel and nickel-rich silicates).[36] Nickel sulfides commonly exist as solid solutions with iron in minerals such as pentlandite and pyrrhotite with the formula Fe9-xNixS8 and Fe7-xNixS6, respectively. Other common Ni-containing minerals are millerite and the arsenide niccolite.[37][38]

In the United States, the term "nickel" or "nick" originally applied to the copper-nickel Flying Eagle cent, which replaced copper with 12% nickel 1857–58, then the Indian Head cent of the same alloy from 1859 to 1864. Still later, in 1865, the term designated the three-cent nickel, with nickel increased to 25%. In 1866, the five-cent shield nickel (25% nickel, 75% copper) appropriated the designation, which has been used ever since for the subsequent 5-cent pieces. This alloy proportion is not ferromagnetic.

An estimated 3.6 million tonnes (t) of nickel per year are mined worldwide; Indonesia (1,800,000 t), the Philippines (400,000 t), Russia (200,000 t), New Caledonia (France) (230,000 t), Canada (180,000 t) and Australia (160,000 t) are the largest producers as of 2023.[75] The largest nickel deposits in non-Russian Europe are in Finland and Greece. Identified land-based sources averaging at least 1% nickel contain at least 130 million tonnes of nickel. About 60% is in laterites and 40% is in sulfide deposits. Also, extensive nickel sources are found in the depths of the Pacific Ocean, especially in an area called the Clarion Clipperton Zone in the form of polymetallic nodules peppering the seafloor at 3.5–6 km below sea level.[76][77] These nodules are composed of numerous rare-earth metals and are estimated to be 1.7% nickel.[78] With advances in science and engineering, regulation is currently being set in place by the International Seabed Authority to ensure that these nodules are collected in an environmentally conscientious manner while adhering to the United Nations Sustainable Development Goals.[79]

Editor’s Note: Although the Aluminum Association has certified hundreds of international aluminum alloys in each of the wrought and cast categories, aluminum metallurgists keep adding new recipes to meet the challenges required in their products, which span a range of applications—transportation, B&C, packaging, and various industrial and consumer products. The focused patent search presented hereafter reviews some of the recent inventions that aluminum metallurgists and engineers have developed in creating aluminum alloy compositions that provide special product properties for their intended applications at ambient and high and low temperatures.

US8636855 — METHODS OF ENHANCING MECHANICAL PROPERTIES OF ALUMINUM ALLOY HIGH PRESSURE DIE CASTINGS — GM Global Technology Operations LLC (USA) — Methods of enhancing mechanical properties of aluminum alloy high pressure die castings are disclosed herein. An aluminum alloy composition forming a casting comprises, by weight of the composition, at least one of a magnesium concentration greater than about 0.2%, a copper concentration greater than about 1.5%, a silicon concentration greater than about 0.5%, and a zinc concentration greater than about 0.3%. After solidification, a casting is cooled to a quenching temperature between about 300°C and about 500°C. Upon attainment of the quenching temperature, the casting is removed from the die and immediately quenched in a quench media. Following quenching, the casting is pre-aged at a reduced temperature between about room temperature and about 100°C. Thereafter, the casting is aged via at least one substantially isothermal aging at one or more elevated temperatures between about 150°C and about 240°C.

All these patents include methods of producing novel aluminum alloy compositions to meet challenging application requirements in a productive process chain. This involves alloying practices as well as downstream processing to produce quality products, including casting, homogenization, extrudability, quenching, and aging (if the alloy is heat treatable) as well as additional final processing (such as anodizing, machining, joining, etc.), if applicable to the intended application.

US7048815 — METHOD OF MAKING A HIGH STRENGTH ALUMINUM ALLOY COMPOSITION — UES, Inc. (USA) — The present invention provides a method of making a high strength aluminum alloy composition. The alloy composition exhibits high tensile strength at ambient temperatures and cryogenic temperatures. In one embodiment of the present invention an aluminum alloy composition is provided comprising between about 6.0% by wt. and about 12.0% by wt. of zinc, between about 2.0% by wt. and about 3.5% by wt. of magnesium, between about 0.01% by wt. and about 0.5% by wt. of scandium, between about 0.05% by wt. and about 0.20% by wt. of zirconium, between about 0.5% by wt. and about 3.0% by wt. of copper, between about 0.10% by wt. and about 0.45% by wt. of manganese, between about 0.02% by wt. and about 0.35% by wt. of iron, between about 0.02% by wt. and about 0.20% by wt. of silicon, between about 0.00% by wt. and about 0.05% by wt. of titanium, between about 0.00% by wt. and about 0.25% by wt. of chromium, between about 0.00% by wt. and about 0.05% by wt. of vanadium, between about 0.00% by wt. and about 0.25% by wt. of hafnium, between about 0.00% by wt. and about 0.20% by wt. of cerium, between about 0.00% by wt. and about 0.20% by wt. of nickel, between about 0.00% by wt. and about 0.20% by wt. of silver, and aluminum. The aluminum alloy composition has a tensile strength of at least 900 MPa at room temperature and at cryogenic temperature for use in the manufacture of cryogenic pumps.

The market price of nickel surged throughout 2006 and the early months of 2007; as of April 5, 2007[update], the metal was trading at US$52,300/tonne or $1.47/oz.[87] The price later fell dramatically; as of September 2017[update], the metal was trading at $11,000/tonne, or $0.31/oz.[88] During the 2022 Russian invasion of Ukraine, worries about sanctions on Russian nickel exports triggered a short squeeze, causing the price of nickel to quadruple in just two days, reaching US$100,000 per tonne.[89][90] The London Metal Exchange cancelled contracts worth $3.9 billion and suspended nickel trading for over a week.[91] Analyst Andy Home argued that such price shocks are exacerbated by the purity requirements imposed by metal markets: only Grade I (99.8% pure) metal can be used as a commodity on the exchanges, but most of the world's supply is either in ferro-nickel alloys or lower-grade purities.[92]

Nickel is obtained through extractive metallurgy: it is extracted from ore by conventional roasting and reduction processes that yield metal of greater than 75% purity. In many stainless steel applications, 75% pure nickel can be used without further purification, depending on impurities.[46]

Use of nickel (as natural meteoric nickel–iron alloy) has been traced as far back as 3500 BCE. Nickel was first isolated and classified as an element in 1751 by Axel Fredrik Cronstedt, who initially mistook the ore for a copper mineral, in the cobalt mines of Los, Hälsingland, Sweden. The element's name comes from a mischievous sprite of German miner mythology, Nickel (similar to Old Nick). Nickel minerals can be green, like copper ores, and were known as kupfernickel – Nickel's copper – because they produced no copper.

Nimonic alloy

Nickel is an excellent alloying agent for certain precious metals and is used in the fire assay as a collector of platinum group elements (PGE). As such, nickel can fully collect all six PGEs from ores, and can partially collect gold. High-throughput nickel mines may also do PGE recovery (mainly platinum and palladium); examples are Norilsk, Russia and the Sudbury Basin, Canada.[94]

Nickel is commonly found in iron meteorites as the alloys kamacite and taenite. Nickel in meteorites was first detected in 1799 by Joseph-Louis Proust, a French chemist who then worked in Spain. Proust analyzed samples of the meteorite from Campo del Cielo (Argentina), which had been obtained in 1783 by Miguel Rubín de Celis, discovering the presence in them of nickel (about 10%) along with iron.[41]

Nickel and its alloys are often used as catalysts for hydrogenation reactions. Raney nickel, a finely divided nickel-aluminium alloy, is one common form, though related catalysts are also used, including Raney-type catalysts.[97]

It is thought that the nickel(I) oxidation state is important to nickel-containing enzymes, such as [NiFe]-hydrogenase, which catalyzes the reversible reduction of protons to H2.[45]

Sensitized persons may show a skin contact allergy to nickel known as a contact dermatitis. Highly sensitized persons may also react to foods with high nickel content.[145] Patients with pompholyx may also be sensitive to nickel. Nickel is the top confirmed contact allergen worldwide, partly due to its use in jewelry for pierced ears.[146] Nickel allergies affecting pierced ears are often marked by itchy, red skin. Many earrings are now made without nickel or with low-release nickel[147] to address this problem. The amount allowed in products that contact human skin is now regulated by the European Union. In 2002, researchers found that the nickel released by 1 and 2 euro coins, far exceeded those standards. This is believed to be due to a galvanic reaction.[148] Nickel was voted Allergen of the Year in 2008 by the American Contact Dermatitis Society.[149] In August 2015, the American Academy of Dermatology adopted a position statement on the safety of nickel: "Estimates suggest that contact dermatitis, which includes nickel sensitization, accounts for approximately $1.918 billion and affects nearly 72.29 million people."[145]

US7255756 — ALUMINUM ALLOY WITH IMPROVED MECHANICAL PROPERTIES AT HIGH TEMPERATURES — National Cheng Kung University (Taiwan) — In view of the increasing need of developing lightweight vehicles, applications of aluminum alloys have been extended to include environments with high temperatures. For example, they may be used to form engine blocks, engine cylinder liners, compressor pistons, disc brakes, etc. Therefore, it has become a very important subject in the light-metal industry to develop aluminum alloys with excellent mechanical properties at high temperatures. In view of the aforesaid, it is highly desired to develop aluminum alloys that can be formed without precipitation hardening treatment and that exhibit improved mechanical properties at high temperatures, including excellent wear resistance, hardness, and thermal stability. Disclosed herein is an aluminum alloy composition consisting essentially of, on the basis of total weight of the composition, 13 to 28 wt. % of silicon, 1.5 to 5 wt. % of a metal element selected from iron and manganese, 3 to 10 wt. % of zinc, 0.5 to 1 wt. % of magnesium, and aluminum as balance. Also disclosed herein is an aluminum alloy product made from said aluminum alloy composition and exhibiting improved mechanical properties at high temperatures, including excellent wear resistance, hardness, and thermal stability. According to this Invention, the aluminum alloy product may be formed by various solidification processes commonly used in the art for the manufacture of alloys, including, but not limited to, spray forming process, gravity casting, die casting, permanent mold casting, and squeeze casting.

US9222151 — ALUMINUM ALLOY EXCELLENT IN HIGH TEMPERATURE STRENGTH AND HEAT CONDUCTIVITY AND METHOD OF PRODUCTION OF SAME — Nippon Light Metal Company, Ltd. (Japan) — The present invention relates to an aluminum alloy which is used for automobile pistons etc. and is excellent in high temperature strength and heat conductivity and to a method of production of the same. An aluminum alloy which is excellent in high temperature strength and heat conductivity by adjusting the composition to one keeping down the drop in high temperature strength and making the Mn content as small as possible to reduce the formation of a solid solution in the aluminum, which aluminum alloy having a composition of ingredients which contains Si: 12 to 16 mass %, N: 0.1 to 2.5 mass %, Cu: 3 to 5 mass %, Mg: 0.3 to 1.2 mass %, Fe: 0.3 to 1.5 mass %, and P: 0.004 to 0.02 mass % and furthermore 0 to 0.1 mass % of Mn and further contains, as necessary, at least one of V: 0.01 to 0.1 mass %, Zr: 0.01 to 0.6 mass %, Cr: 0.01 to 0.2 mass %, and Ti: 0.01 to 0.2 mass %. Also described is a method for producing the aluminum alloy melt. According to need, when casting, the aluminum alloy melt is treated ultrasonically at a temperature of the liquidus line or more. Due to this, it is possible to promote nucleation and make the structure finer and possible to improve the room temperature characteristics of the aluminum alloy. The aim is to secure room temperature elongation and thereby prevent cracking at the time of working. Furthermore, this promotes precipitation and results in the amount in solid solution being reduced and the heat conductivity being improved by that amount.

The average daily exposure is not a threat to human health. Most nickel absorbed by humans is removed by the kidneys and passed out of the body through urine or is eliminated through the gastrointestinal tract without being absorbed. Nickel is not a cumulative poison, but larger doses or chronic inhalation exposure may be toxic, even carcinogenic, and constitute an occupational hazard.[128]

US8771838 — SLIDING BEARING ELEMENT COMPRISING A LEAD-FREE ALUMINUM BEARING METAL LAYER — Federal-Mogul Wiesbaden GmbH (Germany) — The invention relates to a sliding bearing element comprising a supporting layer, an aluminum alloy-based intermediate layer, and an aluminum alloy-based bearing metal layer. The aluminum alloy composition of the intermediate layer includes at least the following components in percent by weight: 3.5 to 4.5 of copper; 0.1 to 1.5% of manganese; 0.1 to 1.5% of magnesium; and 0.1 to 1.0% of silicon. An object of the invention is to improve the laminate having a bearing metal layer and an intermediate layer, both based on an aluminum alloy, and the steel support layer to largely avoid plastic material deformation in use.

US7060139 — HIGH STRENGTH ALUMINUM ALLOY COMPOSITION — UES, Inc. (USA) — The present invention provides a high strength aluminum alloy composition and applications of the high strength aluminum alloy composition for the manufacture of cryogenic pumps. The alloy composition exhibits high tensile strength at ambient temperatures and cryogenic temperatures. The alloy composition can exhibit high tensile strength while maintaining a high elongation in ambient temperatures and cryogenic temperatures. An aluminum based alloy composition comprising: between about 6.0% by wt. and about 12.0% by wt. of zinc; between about 2.0% by wt. and about 3.5% by wt. of magnesium; between about 0.1% by wt. and about 0.5% by wt. of scandium; between about 0.05% by wt. and about 0.20% by wt. of zirconium; between about 0.5% by wt. and about 3.0% by wt. of copper; between about 0.10% by wt. and about 0.45% by wt. of manganese; between about 0.08% by wt. and about 0.35% by wt. of iron; between about 0.07% by wt. and about 0.20% by wt. of silicon; and aluminum, wherein said aluminum alloy has a tensile strength of at least 790 MPa with an elongation of at least 6% at a cryogenic temperature of about -196°C.

Unintentional use of nickel can be traced back as far as 3500 BCE. Bronzes from what is now Syria have been found to contain as much as 2% nickel.[56] Some ancient Chinese manuscripts suggest that "white copper" (cupronickel, known as baitong) was used there in 1700–1400 BCE. This Paktong white copper was exported to Britain as early as the 17th century, but the nickel content of this alloy was not discovered until 1822.[57] Coins of nickel-copper alloy were minted by Bactrian kings Agathocles, Euthydemus II, and Pantaleon in the 2nd century BCE, possibly out of the Chinese cupronickel.[58]

Light Metal Age, read worldwide, is the only U.S. magazine exclusively devoted to primary production and semi-fabrication of aluminum and other light metals.

The purest metal is obtained from nickel oxide by the Mond process, which gives a purity of over 99.99%. The process was patented by Ludwig Mond and has been in industrial use since before the beginning of the 20th century.[85] In this process, nickel is treated with carbon monoxide in the presence of a sulfur catalyst at around 40–80 °C to form nickel carbonyl. In a similar reaction with iron, iron pentacarbonyl can form, though this reaction is slow. If necessary, the nickel may be separated by distillation. Dicobalt octacarbonyl is also formed in nickel distillation as a by-product, but it decomposes to tetracobalt dodecacarbonyl at the reaction temperature to give a non-volatile solid.[13]

US7172664 — METHOD OF MAKING ALUMINUM FOIL FOR FINS — Novelis, Inc. (Canada) — A method is described for making an aluminum alloy foil suitable for application to fins used in heat exchangers. The method comprises providing an aluminum alloy composition containing about 0.27% to about 0.55% by weight of iron, about 0.06% to about 0.55% by weight of silicon and optionally up to about 0.20% by weight of copper; continuously casting a coiled strip from the molten aluminum alloy; cold rolling the continuously cast coil to a final gauge of about 0.076 mm to about 0.152 mm and partially annealing the aluminum alloy sheet at a temperature below about 260°C, with a maximum overheat of about 10°C to anneal the aluminum alloy foil substantially without any recrystallization.

Nickel has two atomic electron configurations, [Ar] 3d8 4s2 and [Ar] 3d9 4s1, which are very close in energy; [Ar] denotes the complete argon core structure. There is some disagreement on which configuration has the lower energy.[23] Chemistry textbooks quote nickel's electron configuration as [Ar] 4s2 3d8,[24] also written [Ar] 3d8 4s2.[25] This configuration agrees with the Madelung energy ordering rule, which predicts that 4s is filled before 3d. It is supported by the experimental fact that the lowest energy state of the nickel atom is a 3d8 4s2 energy level, specifically the 3d8(3F) 4s2 3F, J = 4 level.[26][27]

US9187816 — METHODS OF RESIZING HOLES — General Electric Company (USA) — The present invention generally relates to methods for modifying the cross-sectional area of a hole. More particularly, this invention relates to a coating process that can be controlled to selectively resize a hole, a nonlimiting example being a premix fuel supply hole of a fuel nozzle assembly of a gas turbine. Methods of reducing an initial cross-sectional area of a hole in a component to a predetermined cross-sectional area including preparing a composition comprising at least an aluminum alloy with a melting temperature higher than aluminum, e.g., a Cr-Al alloy, applying the composition to an interior surface of the hole, and then heating the component to cause a metal within the component to diffuse from the component into the composition and react with the aluminum alloy in the composition to form a coating on the interior surface of the hole. The heating step is performed to selectively modify the initial cross-sectional area of the hole and thereby directly attain the predetermined cross-sectional area thereof.

Dietary nickel may affect human health through infections by nickel-dependent bacteria, but nickel may also be an essential nutrient for bacteria living in the large intestine, in effect functioning as a prebiotic.[120] The US Institute of Medicine has not confirmed that nickel is an essential nutrient for humans, so neither a Recommended Dietary Allowance (RDA) nor an Adequate Intake have been established. The tolerable upper intake level of dietary nickel is 1 mg/day as soluble nickel salts. Estimated dietary intake is 70 to 100 μg/day; less than 10% is absorbed. What is absorbed is excreted in urine.[121] Relatively large amounts of nickel – comparable to the estimated average ingestion above – leach into food cooked in stainless steel. For example, the amount of nickel leached after 10 cooking cycles into one serving of tomato sauce averages 88 μg.[122][123]

People can be exposed to nickel in the workplace by inhalation, ingestion, and contact with skin or eye. The Occupational Safety and Health Administration (OSHA) has set the legal limit (permissible exposure limit) for the workplace at 1 mg/m3 per 8-hour workday, excluding nickel carbonyl. The National Institute for Occupational Safety and Health (NIOSH) sets the recommended exposure limit (REL) at 0.015 mg/m3 per 8-hour workday. At 10 mg/m3, nickel is immediately dangerous to life and health.[142] Nickel carbonyl [Ni(CO)4] is an extremely toxic gas. The toxicity of metal carbonyls is a function of both the toxicity of the metal and the off-gassing of carbon monoxide from the carbonyl functional groups; nickel carbonyl is also explosive in air.[143][144]

The one place in the United States where nickel has been profitably mined is Riddle, Oregon, with several square miles of nickel-bearing garnierite surface deposits. The mine closed in 1987.[80][81] The Eagle mine project is a new nickel mine in Michigan's Upper Peninsula. Construction was completed in 2013, and operations began in the third quarter of 2014.[82] In the first full year of operation, the Eagle Mine produced 18,000 t.[82]

Nickel released from Siberian Traps volcanic eruptions is suspected of helping the growth of Methanosarcina, a genus of euryarchaeote archaea that produced methane in the Permian–Triassic extinction event, the biggest known mass extinction.[124]

Several of these patents aim to improve processability as well as properties of automotive heat exchangers made of special aluminum alloy compositions, e.g., tubing extrusion, foil production, brazeability, and corrosion resistance. Others include alloy compositions that aim to improve the performance of automotive die castings and wrought parts at high temperatures and under wear conditions. Some of the compositions cited are used in the manufacture of cryogenic pumps from aluminum alloys having high strength and elongation at cryogenic temperature. Aerospace related patents noted here involve a new Al-Li alloy and a dispersion strengthened aluminum alloy.

US9631879 — ALUMINUM ALLOY FOR EXTRUSION AND DRAWING PROCESSES — Rio Tinto Alcan International Limited (Canada) — An extrudable aluminum alloy composition includes, in weight percent, between 0.60 and 0.90 manganese, between 0.45 and 0.75 copper, between 0.05 and 0.24 magnesium, less than 0.30 iron, less than 0.30 silicon, less than 0.05 titanium, less than 0.05 vanadium, and a Cu/Mg ratio higher or equal to 3. It also relates to aluminum alloy heat exchanger extruded or drawn tube and extruded or drawn aluminum alloy tubing having the above-described aluminum alloy composition. It also relates to a heat exchanger comprising a plurality of extruded or drawn tube sections having the above-described aluminum alloy composition and a process for manufacturing same.

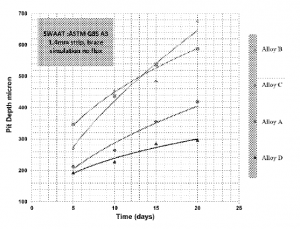

US10669616 — ALUMINUM ALLOY COMPOSITION AND METHOD — Rio Tinto Alcan International Limited (Canada) — An aluminum alloy composition includes, in weight percent: 0.7-1.10 manganese; 0.05-0.25 iron; 0.21-0.30 silicon; 0.005-0.020 nickel; 0.10-0.20 titanium; 0.014 max copper; and 0.05 max zinc, with the balance being aluminum and unavoidable impurities. The alloy may tolerate higher nickel contents than existing alloys, while providing increased corrosion resistance, as well as similar extrudability, strength, and performance. Billets of the alloy may be homogenized at 590-640°C and controlled cooled at less than 250°C per hour. The homogenized billet may be extruded into a product, such as a corrosion resistant aluminum alloy heat exchanger tube.

The US nickel coin contains 0.04 ounces (1.1 g) of nickel, which at the April 2007 price was worth 6.5 cents, along with 3.75 grams of copper worth about 3 cents, with a total metal value of more than 9 cents. Since the face value of a nickel is 5 cents, this made it an attractive target for melting by people wanting to sell the metals at a profit. The United States Mint, anticipating this practice, implemented new interim rules on December 14, 2006, subject to public comment for 30 days, which criminalized the melting and export of cents and nickels.[70] Violators can be punished with a fine of up to $10,000 and/or a maximum of five years in prison.[71] As of September 19, 2013, the melt value of a US nickel (copper and nickel included) is $0.045 (90% of the face value).[72]

Nickel-60 is the daughter product of the extinct radionuclide 60Fe (half-life 2.6 million years). Due to the long half-life of 60Fe, its persistence in materials in the Solar System may generate observable variations in the isotopic composition of 60Ni. Therefore, the abundance of 60Ni in extraterrestrial material may give insight into the origin of the Solar System and its early history.[31]

Nickel is one of four elements (the others are iron, cobalt, and gadolinium)[14] that are ferromagnetic at about room temperature. Alnico permanent magnets based partly on nickel are of intermediate strength between iron-based permanent magnets and rare-earth magnets. The metal is used chiefly in alloys and corrosion-resistant plating.

US10220418 — METHOD AND SYSTEM FOR RECYCLING ALUMINUM ALLOY RIMS USING SPECTROGRAPHIC ANALYSIS — House of Metals Company Limited (Canada) — A method and system of recycling aluminum alloy rims from vehicles, the method and system comprising providing a feed of a plurality of aluminum alloy rims of different alloys, for each rim in the feed of aluminum alloy rims, determining a composition of that aluminum alloy rim, determining a plurality of recycled aluminum alloy composition ranges, and dividing the feed of aluminum alloy rims into a plurality of batches of aluminum alloy rims, each batch of aluminum alloy rims in the plurality of batches of aluminum alloy rims corresponding to an associated recycled aluminum alloy composition range in the plurality of recycled aluminum composition ranges, such that each rim in the plurality of aluminum alloy rims is allocated to an associated batch in the plurality of batches of aluminum alloy rims based on the composition of that aluminum alloy rim.

US9828033 — METHOD FOR PRODUCING A VEHICLE COMPONENT, AND VEHICLE COMPONENT — Aleris Rolled Products Germany GMBH (Germany) — Method for producing a vehicle component, in particular a motor vehicle component, in particular a B-pillar, including providing a first aluminum alloy and a second aluminum alloy. The second alloy composition substantially matches the first aluminum alloy composition. Performing a heat-treatment of the first alloy to increase the ductility of the first alloy. Performing a heat-treatment of the second alloy. The heat-treatment of the first alloy differing from the heat-treatment of the second alloy. Welding together the heat-treated first alloy and the heat-treated second alloy by friction stir or laser welding to obtain a composite part. Shaping the composite parts into a motor vehicle component. The motor vehicle component sub-region of the first alloy can be designed as a predetermined deformation region when a force is applied due to an accident to achieve a good combination of rigid regions for example forming a safety cell, and deformable regions forming a crumple zone for absorbing energy.

Nickel is a chemical element; it has symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive, but large pieces are slow to react with air under standard conditions because a passivation layer of nickel oxide forms on the surface that prevents further corrosion. Even so, pure native nickel is found in Earth's crust only in tiny amounts, usually in ultramafic rocks,[10][11] and in the interiors of larger nickel–iron meteorites that were not exposed to oxygen when outside Earth's atmosphere.

US10634439 — ALUMINUM ALLOY BRAZING SHEET FOR A HEAT EXCHANGER, AND PROCESS FOR PRODUCING THE SAME — UACJ Corporation (Japan) — Provided are an aluminum alloy brazing sheet for heat exchangers, which exhibits excellent formability and brazeability, and an advantageous process for producing the same. The aluminum alloy brazing sheet for heat exchangers according to the present invention is configured such that: the aluminum alloy composition of a core material and the aluminum alloy composition and temper of a filler material are respectively controlled; and a core material portion of the brazing sheet has a specific electric resistivity at room temperature and a specific dispersion ratio of second phase particles. The brazing sheet is configured to further exhibit certain properties in terms of a work hardening exponent (n-value) where a nominal strain is within a range of 1%-2% and in terms of a push-in depth when a penetration crack is generated in a punch stretch forming test using a round-head punch having a diameter of 50 mm.

Kovar

In the 21st century, the high price of nickel has led to some replacement of the metal in coins around the world. Coins still made with nickel alloys include one- and two-euro coins, 5¢, 10¢, 25¢, 50¢, and $1 U.S. coins,[73] and 20p, 50p, £1, and £2 UK coins. From 2012 on the nickel-alloy used for 5p and 10p UK coins was replaced with nickel-plated steel. This ignited a public controversy regarding the problems of people with nickel allergy.[68]

US10557188 — ALUMINUM ALLOY COMPOSITION AND METHOD — Rio Tinto Alcan International Limited (Canada) — The invention relates generally to an aluminum alloy composition and methods of manufacturing and/or homogenizing that can be used with the composition, and more specifically, to an Al-Mn-Si-Ti alloy composition with good corrosion resistance and extrudability, as well as tolerance to increased Ni impurity levels. An aluminum alloy composition includes, in weight percent: 0.5-0.7 manganese; 0.05-0.15 iron; 0.3-0.5 silicon; 0.020 max nickel; 0.05-0.15 titanium; 0.01 max copper; and 0.10 max zinc, with the balance being aluminum and unavoidable impurities. The alloy may also have a combined amount of manganese and silicon of at least 0.8 wt. % and/or a Mn/Si ratio of 2.25 or less. The alloy may tolerate higher nickel contents than existing alloys, while providing increased corrosion resistance, as well as similar extrudability, strength, and performance. Billets or other intermediate products formed of the alloy may be homogenized at 500-595°C and controlled cooled at 400°C per hour or less. The homogenized billet may be extruded into an extruded product, such as an aluminum alloy heat exchanger tube.

Around 27% of all nickel production is used for engineering, 10% for building and construction, 14% for tubular products, 20% for metal goods, 14% for transport, 11% for electronic goods, and 5% for other uses.[15]

Reports show that both the nickel-induced activation of hypoxia-inducible factor (HIF-1) and the up-regulation of hypoxia-inducible genes are caused by depletion of intracellular ascorbate. The addition of ascorbate to the culture medium increased the intracellular ascorbate level and reversed both the metal-induced stabilization of HIF-1- and HIF-1α-dependent gene expression.[150][151]

US10392684 — METHOD FOR THE PRODUCTION OF AN ANODIZED, TURNED MECHANICAL PART MADE FROM 6XXX ALLOY AND HAVING LOW ROUGHNESS AFTER ANODIZATION — Constellium Extrusion Decin S.R.O. (Czechoslovakia) — The invention relates to a method for the production of a mechanical part, comprising the following successive steps: casting of a billet of aluminum alloy with a composition (in weight %) of 0.4-3.0 Si; 0.6-2.0 Mg; 0.20-1.0 Cu; 0.15-1.8 Fe; Mn<0.5; Ni<1; Ti<0.15; Cr<0.35; Bi<0.8; Pb<0.4; Zr<0.04; other elements <0.05 each and <0.15 total, the remainder being aluminum; homogenization of the billet; extrusion of the billet in order to obtain an extruded product; quenching while at extrusion heat; optional cold-deformation and/or straightening, typically by means of pulling and/or drawing, and/or curing of the extruded product; tempering; optional cold-deformation of the extruded product, typically by drawing; machining of the resulting extruded product in order to obtain a turned mechanical part; optional shaping of the resulting mechanical part; anodizing of the resulting mechanical part at a temperature of between 15 and 40°C with a solution comprising between 100 and 250 g/l sulfuric acid and between 10 and 30 g/l oxalic acid and between 5 and 30 g/l of at least one polyol. The anodized turned mechanical parts obtained using the method of the invention have, in particular, advantageous roughness and excellent corrosion resistance and can be used, particularly, as brake pistons or gearbox elements.

US9982328 — CASTING MADE FROM ALUMINIUM ALLOY, HAVING HIGH HOT CREEP AND FATIGUE RESISTANCE — Rio Tinto Alcan International Limited (Canada) — The subject of the invention is a cast part with high mechanical resistance and hot creep strength, in particular around 300°C or even above, combined with a high yield strength at ambient temperature and high low cycle and high cycle mechanical fatigue strength, and with good ductility from ambient temperature up to 300°C, made of aluminum alloy of chemical composition, expressed in percentages by weight: Si: 3-11%, preferably 5.0-9.0% Fe<0.50%, preferably <0.30%, preferably still <0.19% or even 0.12% Cu: 2.0-5.0%, preferably 2.5-4.2%, preferably still 3.0-4.0% Mn: 0.05-0.50%, preferably 0.08-0.20% Mg: 0.10-0.25%, preferably 0.10-0.20% Zn: <0.30%, preferably <0.10% Ni: <0.30%, preferably <0.10% V: 0.05-0.19%, preferably 0.08-0.19%, preferably still 0.10-0.19% Zr: 0.05-0.25%, preferably 0.08-0.20% Ti: 0.01-0.25%, preferably 0.05-0.20% other elements <0.05% each and 0.15% in total, the rest aluminum. It more particularly relates to cylinder heads for supercharged diesel or petrol internal combustion engines.

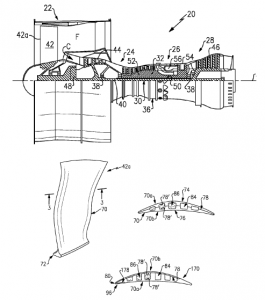

US9233414 — ALUMINUM AIRFOIL — United Technologies Corporation (USA) — A method of making an aluminum airfoil includes brazing a first airfoil piece and a second airfoil piece together using a braze material that includes an element selected from magnesium and zinc, to form a braze joint between the first airfoil piece and the second airfoil piece. At least one of the first airfoil piece or the second airfoil piece has an aluminum alloy composition that includes greater than 0.8% by weight of zinc. In a further non-limiting embodiment of any of the foregoing embodiments, the aluminum alloy composition includes greater than 4% by weight of the zinc. A further non-limiting embodiment of any of the foregoing embodiments includes a hollow cavity between the first airfoil piece the second airfoil piece.

US9267189 — METHODS FOR FORMING DISPERSION-STRENGTHENED ALUMINUM ALLOYS — Honeywell International Inc. (USA) — In accordance with an exemplary embodiment, a method of forming a dispersion-strengthened aluminum alloy metal useful in aerospace applications includes the steps of providing a dispersion-strengthened aluminum alloy composition in a powdered form, directing a low energy density laser beam at a portion of the powdered alloy composition, and withdrawing the laser beam from the portion of the powdered alloy composition. After withdrawal of the laser beam, the portion of the powdered alloy composition cools at a rate greater than or equal to about 10 6 °C per second, thereby forming the dispersion-strengthened aluminum alloy metal. The alloys used in this disclosure are preferably based on Al-Fe-V-Si. In one particular embodiment, the dispersoid may be a fine, nearly spherical phase with a composition approximating Al 12(Fe,V) 3Si. This silicide dispersoid may make up from 5 to 45 volume-% of the alloy, preferably from 15 to 40 volume-%. This gives a range of alloy compositions all having a [Fe+V]:Si ratio within the range 2:1 to 5:1. These Al-Fe-V-Si alloys may contain from 0.02 to 0.5 at % of a fifth element, which may be Mn, Mo, W, Cr, Ta, Zr, Ce, Er, Sc, Nd, Yb, or Y.

Nickel-62 has the highest binding energy per nucleon of any nuclide: 8.7946 MeV/nucleon.[28][29] Its binding energy is greater than both 56Fe and 58Fe, more abundant nuclides often incorrectly cited as having the highest binding energy.[30] Though this would seem to predict nickel as the most abundant heavy element in the universe, the high rate of photodisintegration of nickel in stellar interiors causes iron to be by far the most abundant.[30]

Aside from primary aluminum alloying practices that use master alloys or pure elements to alloy primary grade aluminum, most common casthouse practices involve some or even a major portion of secondary aluminum additions and require special consideration when alloying, as has been done in creating many of the new and innovative aluminum alloys presented here. For more information on common casthouse practices, interested readers can search the international patents presented in the August 2020 issue of LMA, which focused on aluminum remelting and casthouse strategies.

Nickel tetracarbonyl (Ni(CO)4), discovered by Ludwig Mond,[43] is a volatile, highly toxic liquid at room temperature. On heating, the complex decomposes back to nickel and carbon monoxide:

On geophysical evidence, most of the nickel on Earth is believed to be in Earth's outer and inner cores. Kamacite and taenite are naturally occurring alloys of iron and nickel. For kamacite, the alloy is usually in the proportion of 90:10 to 95:5, though impurities (such as cobalt or carbon) may be present. Taenite is 20% to 65% nickel. Kamacite and taenite are also found in nickel iron meteorites.[40]

The most common oxidation state of nickel is +2, but compounds of Ni0, Ni+, and Ni3+ are well known, and the exotic oxidation states Ni2− and Ni− have been characterized.[42]

99.9% nickel five-cent coins were struck in Canada (the world's largest nickel producer at the time) during non-war years from 1922 to 1981; the metal content made these coins magnetic.[66] During the war years 1942–1945, most or all nickel was removed from Canadian and US coins to save it for making armor.[60] Canada used 99.9% nickel from 1968 in its higher-value coins until 2000.[67]

However, each of these two configurations splits into several energy levels due to fine structure,[26][27] and the two sets of energy levels overlap. The average energy of states with [Ar] 3d9 4s1 is actually lower than the average energy of states with [Ar] 3d8 4s2. Therefore, the research literature on atomic calculations quotes the ground state configuration as [Ar] 3d9 4s1.[23]

Although most nickel in the earth's crust exists as oxides, economically more important nickel ores are sulfides, especially pentlandite. Major production sites include the Sudbury region, Canada (which is thought to be of meteoric origin), New Caledonia in the Pacific, Western Australia, and Norilsk, Russia.[13]

Many Ni(III) compounds are known. Ni(III) forms simple salts with fluoride[50] or oxide ions. Ni(III) can be stabilized by σ-donor ligands such as thiols and organophosphines.[44]

The major source of nickel exposure is oral consumption, as nickel is essential to plants.[126] Typical background concentrations of nickel do not exceed 20 ng/m3 in air, 100 mg/kg in soil, 10 mg/kg in vegetation, 10 μg/L in freshwater and 1 μg/L in seawater.[127] Environmental concentrations may be increased by human pollution. For example, nickel-plated faucets may contaminate water and soil; mining and smelting may dump nickel into wastewater; nickel–steel alloy cookware and nickel-pigmented dishes may release nickel into food. Air may be polluted by nickel ore refining and fossil fuel combustion. Humans may absorb nickel directly from tobacco smoke and skin contact with jewelry, shampoos, detergents, and coins. A less common form of chronic exposure is through hemodialysis as traces of nickel ions may be absorbed into the plasma from the chelating action of albumin.[citation needed]

US10655635 — ALUMINUM AIRFOIL — United Technologies Corporation (USA) — An airfoil includes a first airfoil piece and a second airfoil piece bonded to the first airfoil piece at a joint. The first airfoil piece and the second airfoil piece are formed of aluminum alloys. At least one of the aluminum alloys is an aluminum alloy composition that has greater than 0.8% by weight of zinc.

Nickel is obtained from nickel carbonyl by one of two processes. It may be passed through a large chamber at high temperatures in which tens of thousands of nickel spheres (pellets) are constantly stirred. The carbonyl decomposes and deposits pure nickel onto the spheres. In the alternate process, nickel carbonyl is decomposed in a smaller chamber at 230 °C to create a fine nickel powder. The byproduct carbon monoxide is recirculated and reused. The highly pure nickel product is known as "carbonyl nickel".[86]

Nickel is used in many recognizable industrial and consumer products, including stainless steel, alnico magnets, coinage, rechargeable batteries (e.g. nickel–iron), electric guitar strings, microphone capsules, plating on plumbing fixtures,[93] and special alloys such as permalloy, elinvar, and invar. It is used for plating and as a green tint in glass. Nickel is preeminently an alloy metal, and its chief use is in nickel steels and nickel cast irons, in which it typically increases the tensile strength, toughness, and elastic limit. It is widely used in many other alloys, including nickel brasses and bronzes and alloys with copper, chromium, aluminium, lead, cobalt, silver, and gold (Inconel, Incoloy, Monel, Nimonic).[84]

Nickel is used as a binder in the cemented tungsten carbide or hardmetal industry and used in proportions of 6% to 12% by weight. Nickel makes the tungsten carbide magnetic and adds corrosion-resistance to the cemented parts, though the hardness is less than those with cobalt binder.[101]

US9857128 — HEAT TRANSFER TUBE AND METHOD FOR PRODUCING SAME — Mitsubishi Aluminum Co., Ltd. (Japan) — An extruded heat transfer tube with the body of the tube having a flat tube shape with multiple holes including multiple passage of fluid.an internal passage made of an extruded material of an aluminum alloy having a composition that includes 0.3 mass % or more and less than 0.8 mass % of Mn; more than 0.1 mass % and less than 0.32 mass % of Si; 0.3 mass % or less of Fe; 0.06 mass % or more and 0.3 mass % or less of Ti; and Al balance including inevitable impurities, a ratio of a Mn content to a Si content, Mn %/Si %, exceeding 2.5. The extruded heat transfer tube further includes a Zn-containing layer provided directly on an outer surface of the tube body and has excellent corrosion resistance.

Nickel titanium is an alloy of roughly equal atomic percentages of its constituent metals which exhibits two closely related and unique properties: the shape memory effect and superelasticity.

US8025748 — Al-Mn BASED ALUMINUM ALLOY COMPOSITION COMBINED WITH A HOMOGENIZATION TREATMENT — Rio Tinto Alcan International Limited (Canada) — The invention relates to an aluminum-manganese (Al-Mn) based alloy composition and, more particularly, it relates to an Al-Mn based alloy composition combined with a homogenization treatment for extruded and brazed heat exchanger tubing. An extrudable aluminum alloy billet includes an aluminum alloy composition including, in weight percent, between 0.90 and 1.30 manganese, between 0.05 and 0.25 iron, between 0.05 and 0.25 silicon, between 0.01 and 0.02 titanium, less than 0.01 copper, less than 0.01 nickel, and less than 0.05 magnesium, the aluminum alloy billet being homogenized at a temperature ranging between 550 and 600°C.

Some tetracoordinate nickel(II) complexes, e.g. bis(triphenylphosphine)nickel chloride, exist both in tetrahedral and square planar geometries. The tetrahedral complexes are paramagnetic; the square planar complexes are diamagnetic. In having properties of magnetic equilibrium and formation of octahedral complexes, they contrast with the divalent complexes of the heavier group 10 metals, palladium(II) and platinum(II), which form only square-planar geometry.[42]

Traditionally, most sulfide ores are processed using pyrometallurgical techniques to produce a matte for further refining. Hydrometallurgical techniques are also used. Most sulfide deposits have traditionally been processed by concentration through a froth flotation process followed by pyrometallurgical extraction. The nickel matte is further processed with the Sherritt-Gordon process. First, copper is removed by adding hydrogen sulfide, leaving a concentrate of cobalt and nickel. Then, solvent extraction is used to separate the cobalt and nickel, with the final nickel content greater than 86%.[83]

US9885995 — ALUMINUM ALLOY AND PROCESS FOR PRODUCING ALUMINUM ALLOY EXTRUSIONS — Showa Denko K.K. (Japan) — The present invention relates to an aluminum alloy, a production method of an aluminum alloy extruded member, a production method of a photoconductor drum substrate, an aluminum alloy extruded member, and a photoconductor drum substrate. An outer surface of an aluminum alloy tube used for the substrate is required to have a high surface smoothness so that a photosensitive layer having a uniform thickness can be applied thereon. In recent years, a non-machined tube, such as a drawn tube obtained by drawing an aluminum alloy extruded tube, an ironed tube obtained by ironing an aluminum alloy extruded tube, etc., has come into use. In such a non-machined tube, the surface quality of the outer surface is largely affected not only by the processing accuracy of the drawing process or the ironing process as a final process but also by the surface quality of the outer surface of the extruded tube and, in order to assuredly make the outer surface of the non-machined tube into a high smooth surface, it is required to improve the surface quality of the outer surface of the extruded tube. An aluminum alloy for this purpose has a composition consisting of Si: 0.03 to 0.6 mass %, Fe: 0.1 to 0.7 mass %, Cu: 0.05 to 0.20 mass %, Mn: 1.0 to 1.5 mass %, Mg: 0.01 to 0.1 mass %, Zn: 0 to 0.1 mass %, Ti: 0 to 0.1 mass %, and the balance being Al and inevitable impurities.

Invar

Nickel(I) complexes are uncommon, but one example is the tetrahedral complex NiBr(PPh3)3. Many nickel(I) complexes have Ni–Ni bonding, such as the dark red diamagnetic K4[Ni2(CN)6] prepared by reduction of K2[Ni2(CN)6] with sodium amalgam. This compound is oxidized in water, liberating H2.[44]

In medieval Germany, a metallic yellow mineral was found in the Ore Mountains that resembled copper ore. But when miners were unable to get any copper from it, they blamed a mischievous sprite of German mythology, Nickel (similar to Old Nick), for besetting the copper. They called this ore Kupfernickel from German Kupfer 'copper'.[59][60][61][62] This ore is now known as the mineral nickeline (formerly niccolite[63]), a nickel arsenide. In 1751, Baron Axel Fredrik Cronstedt tried to extract copper from kupfernickel at a cobalt mine in the village of Los, Sweden, and instead produced a white metal that he named nickel after the spirit that had given its name to the mineral.[64] In modern German, Kupfernickel or Kupfer-Nickel designates the alloy cupronickel.[21]

About 68% of world production is used in stainless steel. A further 10% is used for nickel-based and copper-based alloys, 9% for plating, 7% for alloy steels, 3% in foundries, and 4% in other applications such as in rechargeable batteries,[15] including those in electric vehicles (EVs).[16] Nickel is widely used in coins, though nickel-plated objects sometimes provoke nickel allergy. As a compound, nickel has a number of niche chemical manufacturing uses, such as a catalyst for hydrogenation, cathodes for rechargeable batteries, pigments and metal surface treatments.[17] Nickel is an essential nutrient for some microorganisms and plants that have enzymes with nickel as an active site.[18]

A second common refining process is leaching the metal matte into a nickel salt solution, followed by electrowinning the nickel from solution by plating it onto a cathode as electrolytic nickel.[84]

Nickel is a silvery-white metal with a slight golden tinge that takes a high polish. It is one of only four elements that are ferromagnetic at or near room temperature; the others are iron, cobalt and gadolinium. Its Curie temperature is 355 °C (671 °F), meaning that bulk nickel is non-magnetic above this temperature.[20][14] The unit cell of nickel is a face-centered cube; it has lattice parameter of 0.352 nm, giving an atomic radius of 0.124 nm. This crystal structure is stable to pressures of at least 70 GPa. Nickel is hard, malleable and ductile, and has a relatively high electrical and thermal conductivity for transition metals.[21] The high compressive strength of 34 GPa, predicted for ideal crystals, is never obtained in the real bulk material due to formation and movement of dislocations. However, it has been reached in Ni nanoparticles.[22]

Nickel is naturally magnetostrictive: in the presence of a magnetic field, the material undergoes a small change in length.[98][99] The magnetostriction of nickel is on the order of 50 ppm and is negative, indicating that it contracts.[100]

Identified land-based resources throughout the world averaging 1% nickel or greater comprise at least 130 million tons of nickel (about the double of known reserves). About 60% is in laterites and 40% in sulfide deposits.[39]

Nickel compounds are classified as human carcinogens[129][130][131][132] based on increased respiratory cancer risks observed in epidemiological studies of sulfidic ore refinery workers.[133] This is supported by the positive results of the NTP bioassays with Ni sub-sulfide and Ni oxide in rats and mice.[134][135] The human and animal data consistently indicate a lack of carcinogenicity via the oral route of exposure and limit the carcinogenicity of nickel compounds to respiratory tumours after inhalation.[136][137] Nickel metal is classified as a suspect carcinogen;[129][130][131] there is consistency between the absence of increased respiratory cancer risks in workers predominantly exposed to metallic nickel[133] and the lack of respiratory tumours in a rat lifetime inhalation carcinogenicity study with nickel metal powder.[138] In the rodent inhalation studies with various nickel compounds and nickel metal, increased lung inflammations with and without bronchial lymph node hyperplasia or fibrosis were observed.[132][134][138][139] In rat studies, oral ingestion of water-soluble nickel salts can trigger perinatal mortality in pregnant animals.[140] Whether these effects are relevant to humans is unclear as epidemiological studies of highly exposed female workers have not shown adverse developmental toxicity effects.[141]

Radioactive nickel-56 is produced by the silicon burning process and later set free in large amounts in type Ia supernovae. The shape of the light curve of these supernovae at intermediate to late-times corresponds to the decay via electron capture of 56Ni to cobalt-56 and ultimately to iron-56.[32] Nickel-59 is a long-lived cosmogenic radionuclide; half-life 76,000 years. 59Ni has found many applications in isotope geology. 59Ni has been used to date the terrestrial age of meteorites and to determine abundances of extraterrestrial dust in ice and sediment. Nickel-78, with a half-life of 110 milliseconds, is believed an important isotope in supernova nucleosynthesis of elements heavier than iron.[33] 48Ni, discovered in 1999, is the most proton-rich heavy element isotope known. With 28 protons and 20 neutrons, 48Ni is "doubly magic", as is 78Ni with 28 protons and 50 neutrons. Both are therefore unusually stable for nuclei with so large a proton–neutron imbalance.[9][34]

Originally, the only source for nickel was the rare Kupfernickel. Beginning in 1824, nickel was obtained as a byproduct of cobalt blue production. The first large-scale smelting of nickel began in Norway in 1848 from nickel-rich pyrrhotite. The introduction of nickel in steel production in 1889 increased the demand for nickel; the nickel deposits of New Caledonia, discovered in 1865, provided most of the world's supply between 1875 and 1915. The discovery of the large deposits in the Sudbury Basin in Canada in 1883, in Norilsk-Talnakh in Russia in 1920, and in the Merensky Reef in South Africa in 1924 made large-scale nickel production possible.[57]

Ni(III) occurs in nickel oxide hydroxide, which is used as the cathode in many rechargeable batteries, including nickel–cadmium, nickel–iron, nickel–hydrogen, and nickel–metal hydride, and used by certain manufacturers in Li-ion batteries.[51]

US9783871 — METHOD OF PRODUCING ALUMINIUM ALLOYS CONTAINING LITHIUM — Aleris Rolled Products Germany GMBH (Germany) — A method of producing molten aluminum-lithium alloys for casting a feedstock in the form of an ingot, the method including the steps of: preparing a molten first aluminum alloy with a composition A which is free from lithium as purposive alloying element, transferring the first aluminum alloy to an induction melting furnace, adding lithium to the first aluminum alloy in the induction melting furnace to obtain a molten second aluminum alloy with a composition B having lithium as purposive alloying element, optionally adding further alloying elements to the second aluminum alloy, transferring the second alloy via a metal conveying trough from the induction melting furnace to a casting station.

The four halides form nickel compounds, which are solids with molecules with octahedral Ni centres. Nickel(II) chloride is most common, and its behavior is illustrative of the other halides. Nickel(II) chloride is made by dissolving nickel or its oxide in hydrochloric acid. It is usually found as the green hexahydrate, whose formula is usually written NiCl2·6H2O. When dissolved in water, this salt forms the metal aquo complex [Ni(H2O)6]2+. Dehydration of NiCl2·6H2O gives yellow anhydrous NiCl2.[48]

Because nickel is resistant to corrosion, it was occasionally used as a substitute for decorative silver. Nickel was also occasionally used in some countries after 1859 as a cheap coinage metal (see above), but in the later years of the 20th century, it was replaced by cheaper stainless steel (i.e., iron) alloys, except in the United States and Canada.[65]

US10260136 — ALUMINUM ALLOY FOR DIE CASTING AND METHOD OF HEAT TREATING THE SAME — Hyundai Motor Company (Korea) — Disclosed are an aluminum alloy composition for die casting and a method of heat treating the same. The aluminum alloy composition contains precipitation of an Mg–Zn-based strengthening phase through heat treatment to thus enhance strength thereof. In one aspect of the present invention, provided is an aluminum alloy composition for die casting. The aluminum alloy composition may comprise: silicon (Si) in an amount of about 9.6 to 12.0 wt. %; magnesium (Mg) in an amount of about 1.5 to 3.0 wt. %; zinc (Zn) in an amount of about 3.0 to 6.0 wt. %; iron (Fe) in an amount of about 1.3 wt. % or less but greater than 0 wt. %; manganese (Mn) in an amount of about 0.5 wt. % or less but greater than 0 wt. %; nickel (Ni) in an amount of about 0.5 wt. % or less but greater than 0 wt. %; tin (Sn) in an amount of about 0.2 wt. % or less but greater than 0 wt. %; and aluminum (Al) constituting the remaining balance of the aluminum alloy composition. Unless otherwise indicated herein, all the wt. % are based on the total weight of the aluminum alloy composition. The aluminum alloy may further include copper (Cu) in an amount of about 0.3 wt. % or less and titanium (Ti) in an amount of about 0.3 wt. % or less, based on the total weight of the alloy composition. Preferably, the sum of amounts of Mg and Zn may be of about 6 to 8 wt. %, based on the total weight of the aluminum alloy composition. Preferably, the aluminum alloy composition may have a ratio of Mg/Zn ratio about 2.0 or greater.

Raney nickel is widely used for hydrogenation of unsaturated oils to make margarine, and substandard margarine and leftover oil may contain nickel as a contaminant. Forte et al. found that type 2 diabetic patients have 0.89 ng/mL of Ni in the blood relative to 0.77 ng/mL in control subjects.[105]

It was not recognized until the 1970s, but nickel is known to play an important role in the biology of some plants, bacteria, archaea, and fungi.[106][107][108] Nickel enzymes such as urease are considered virulence factors in some organisms.[109][110] Urease catalyzes hydrolysis of urea to form ammonia and carbamate.[107][106] NiFe hydrogenases can catalyze oxidation of H2 to form protons and electrons; and also the reverse reaction, the reduction of protons to form hydrogen gas.[107][106] A nickel-tetrapyrrole coenzyme, cofactor F430, is present in methyl coenzyme M reductase, which can catalyze the formation of methane, or the reverse reaction, in methanogenic archaea (in +1 oxidation state).[111] One of the carbon monoxide dehydrogenase enzymes consists of an Fe-Ni-S cluster.[112] Other nickel-bearing enzymes include a rare bacterial class of superoxide dismutase[113] and glyoxalase I enzymes in bacteria and several eukaryotic trypanosomal parasites[114] (in other organisms, including yeast and mammals, this enzyme contains divalent Zn2+).[115][116][117][118][119]

Ni(IV) remains a rare oxidation state and very few compounds are known. Ni(IV) occurs in the mixed oxide BaNiO3.[52][53][54][55]

Natural nickel is composed of five stable isotopes, 58Ni, 60Ni, 61Ni, 62Ni and 64Ni, of which 58Ni is the most abundant (68.077% natural abundance).[9]

At least 26 nickel radioisotopes have been characterized; the most stable are 59Ni with half-life 76,000 years, 63Ni (100 years), and 56Ni (6 days). All other radioisotopes have half-lives less than 60 hours and most these have half-lives less than 30 seconds. This element also has one meta state.[9]

In the second Oz book, The Marvelous Land of Oz (by L. Frank Baum, published by Reilly & Britton, 1904), the Tin Woodman states that he has had his tin body nickel-plated. He is thereafter very careful not to allow his nickel plating to get scratched, nicked, or marred.[152]

63Ni, with a half-life of 100.1 years, is useful in krytron devices as a beta particle (high-speed electron) emitter to make ionization by the keep-alive electrode more reliable.[102] It is being investigated as a power source for betavoltaic batteries.[103][104]

This behavior is exploited in the Mond process for purifying nickel, as described above. The related nickel(0) complex bis(cyclooctadiene)nickel(0) is a useful catalyst in organonickel chemistry because the cyclooctadiene (or cod) ligands are easily displaced.

0086-813-8127573

0086-813-8127573