Free CNC Projects - woodworking cnc projects

Martensite phaseformula

What is the best drill bits for metal between cobalt drill bits and titanium drill bits for your drilling project? This mostly relies on your short and long-term working goals.

Cobalt drill bits and titanium coated bits are two of the most durable forms of drill bits. Both cobalt and titanium drill bits are very strong and powerful. By coming into contact with other metals, they are designed to prevent overheating, that is why it is so necessary to use an HSS drill bit for metal drilling.

When it comes to solids, a martensitic transformation is a polymorphic phase transition done by altering the crystal structure in the solid state that is athermal and diffusionless.

However, titanium and cobalt bits have a non-branded angled edge. When using them on wood surfaces, there is a risk of bit-shifting from the surface, which can slice or damage the wood workpiece.

How ismartensiteformed

Due to its incredible strength and hardness, martensite is one of the most important microstructures in steel. martensite is formed in carbon steels by rapidly quenching iron (austenite form) at low temperature. martensite is a supersaturated solid solution of carbon in iron that was called after Adolf Marten, a German metallurgist.

Martensiteformula

It is necessary to use a constant cooling condition to simulate the experimental quenching process accurately. Higher temperatures above the martensitic start (Ms) temperature cause randomly distributed nuclei to become dormant because the driving force is insufficient to keep them active. When the temperature drops below Ms temperature, The martensitic phase transformation is activated by the change in chemical driving force over elastic energy penalty generated by the transformation strains.

Martensitevs austenite

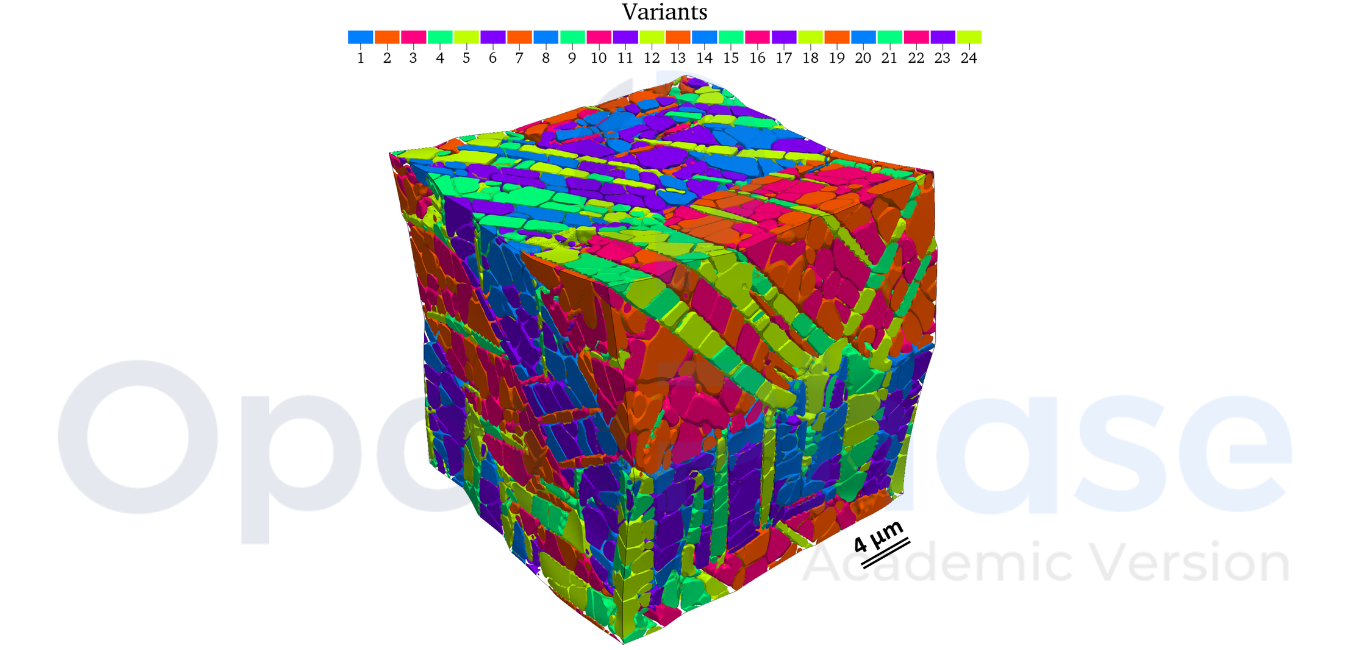

Illustration of the three-dimensional representation of simulated Martensite microscopic microstructures in Figure 1. According to the image, the resulting microstructure displays regular combinations of unique K-S variants in a lamellar arrangement, in which K-S variants with the same Bain strain grow together form blocks.

Both cobalt bits and titanium drill bits are common for metal applications, including materials such as iron, steel, and aluminum. They are used to make holes and drill screws through the tough metal. These bits are built to operate with high-speed drills, ensuring they can spin at maximum speeds without losing their shape when drilling through hard materials.

Titanium bits have a coating of titanium nitride, So while sharpening the bits there is the risk of losing the bit coating when you use a sharpener. Therefore, titanium bits have less lifespan

Martensitemicrostructure

A randomized nucleation technique is used, which chooses two random martensite variations from all available martensite variants each time a new nucleation site is formed. In order to distinguish between different martensite variants, the indices of these variants are denoted by notations derived from KurdjumovâSach (KS) orientation relationships.

Martensitestructure

In the file "ProjectInput.opi", you can find all the input parameters that are relevant to the simulation. All of the simulation parameters can be found in the referenced document [1].

The austenite is assumed to be heated to 950 degrees Celsius before being quenched to room temperature at a continuous cooling rate of 100 degrees Celsius per second, which is incorporated in the simulations.

The hardness and strength of carbon steel improve as the amount of martensite in the steel increases, but the toughness of the steel diminishes. These effects are primarily influenced by the amount of carbon present in the steel in question.

They also look similar to the twist bits (wood bits). They differ in their tips. Wood drill bits have a brad, which is a sharp, pointed piece, on their tips, it allows the bit to drill into the wood without slipping.

Martensite phaseexample

For soft metals and wood drill, you can choose titanium drill bits. It works well and cost you less. However, they need more regular sharpening and can lose their coating in the operation.

These two drill bits are the most powerful among any other Drill Bits. They are designed to cut hard materials. While they're used more commonly for metal, and also work for hardwoods.

A built-in example, "Martensite C01", in OpenPhase®, simulates the martensitic transition in low carbon steel. Steel has been used as the model material, and it has 2 wt% Mn and 1 wt% Cr and various carbon percentages that can be specified.

Cobalt bits have no coating, So there is no risk of its surface stripping away while sharpening them. Therefore, cobalt drill bits

Two types of High-Speed Steel (HSS) bits are cobalt and titanium drill bits for metal. They are both made of steel, but their coating is where it make difference between them. Cobalt and titanium drill bits are able to work with any power drill. These drill bits perform many of the same functions, and look similar, apart from their color.

However, there are a few major variations between cobalt drill bits and titanium drill bits, Here you will find those differences.

Martensite phasediagram

You can choose cobalt drill bits if you have a good investment amount and long-term projects, as we discussed earlier cobalt bits are a bit expensive, although they have a longer life and they are more durable. They are perfect to drill hard and tough metals.

When you visit or interact with our sites, services or tools, we or our authorised service providers may use cookies for storing information to help provide you with a better, faster and safer experience and for marketing purposes.

There are many similarities between cobalt drill bits for metal and titanium bits, and they are also used for some similar applications, but there are few differences. The main variations come in the composition of these drill bits. Cobalt and titanium do not work exactly the same, so cobalt and titanium coatings will make your drill bits perform differently from each other.

0086-813-8127573

0086-813-8127573