Fujian Postal Codes | Zipcode - fujian china postal code

Carbon fibermachining service

For more details including technical information on Avient’s carbon fiber composite products, download the product bulletin.

CFRP materials are highly regarded for their superior strength-to-weight ratio, corrosion resistance, stiffness and durability. Carbon fiber’s high tensile strength and low density enable light weighting and make it an excellent alternative to heavy metals, like steel. Due to the inherent corrosion resistance of thermoset resins, CFRP products do not rust or corrode and in turn have a longer product lifetime than typical metal materials.

CFRP products serve an important role in the building and construction industry – specifically in bridge support, support beams and concrete reinforcement. The superior strength, low weight, corrosion resistance and ability to adhere to concrete make carbon fiber composites an excellent material for infrastructure applications that require strength and durability. Compared to traditional steel used in concrete reinforcement and infrastructure applications, carbon fiber composites offer higher tensile strength, lower density and more versatility in end-use applications.

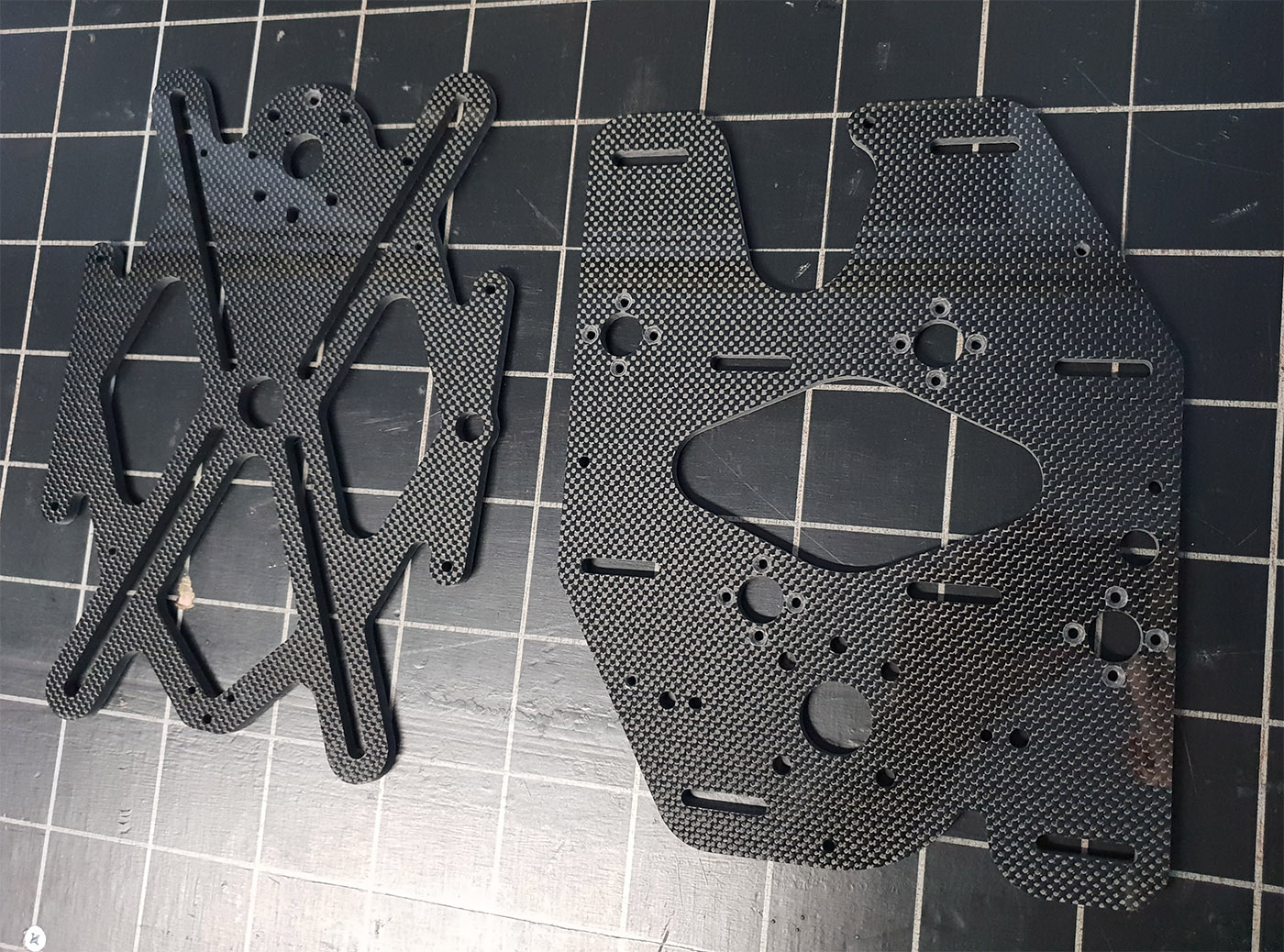

Our carbon fiber sheets machining service includes manufacture of elements from carbon fiber sheet with a perfectly smooth side (A side) with gloss finish (mirror finish) and the other side (B side) with a slightly rough surface (so called peel-ply surface) which is perfect in for bonding. Upon request we also supply products with smooth surfaces on both sides. For this purpose we use a thicker CFRP sheet (e.g. 6.2mm thick instead of 6mm) that later undergoes treatment with a precise wide-belt sander (B side) with accuracy up to 0.05mm. That produces a mirror finish (gloss) on the A side and a matt finish on the B side. The below picture describes both sides of the manufactured detail.

Machinable carbon fibervscarbon fiber

We supply carbon sheets – we can manufacture sheets in custom sizes, thickness and fabric type (e.g. Aramid/Kevlar or Texalium sheets).Possible uses for carbon sheet: panels, grippers, interior decor elements, racing car panels, RC models, device casing etc.Worldwide Shipping: we ship worldwide.For details on international shipping costs -> see the shipping cost.

© 2015 – 2024. Avient Corporation. All Rights Reserved. Copyright & Legal Disclaimer. | Privacy Statement | California Privacy Rights | Email Fraud Information | Site Map | Web Design & Development by Upward Brand Interactions | Standard Contractual Clauses

We supply carbon fiber CNC machining services with 3-axis and 4-axis milling CNC machines that offer an accuracy up to 0.05 mm (0.002") and working field of 200 x 300 cm (78 x 118"). Our in house CNC machining capability allows us to efficiently and cost effectively cut your carbon fiber (CFRP) parts.

Yes we do. Our company also provides services related to two-sided milling of carbon fiber sheets and most often these services relate to milling slots for counter-sunk screws.

Dimensions: cut to any dimensions (280x140 cm max / 110" in x 55" in).Fiber layout: 2/2 (also sheets with 1/1 are available).Finish: single or double side gloss, protection against UV.Thickness – available: 0.5 mm, 1 mm, 1.5 mm, 2 mm, 2.5 mm, 3 mm, 3.5 mm, 4 mm, 4,5 mm, 5 mm, 5.5 mm, 6 mm, 6.5 mm, 7 mm, 7.5 mm, 8 mm, 8.5 mm, 9 mm, 9.5 mm, 10 mm, 10.5 mm, 11 mm, 11.5 mm, 12 mm, 12.5 mm, 13 mm, 13.5 mm, 14 mm, 14.5 mm, 15 mm, 15.5 mm, 16 mm, 16.5 mm, 17 mm, 17.5 mm, 18 mm, 18.5 mm, 19 mm, 19.5 mm, 20 mm, 20.5 mm, 21 mm, 21.5 mm, 22 mm, 22.5 mm, 23 mm, 23.5 mm, 24 mm, 24.5 mm, 25 mm, 25.5 mm, 26 mm, 26.5 mm, 27 mm, 27.5 mm, 28 mm, 28.5 mm, 29 mm, 29.5 mm, 30 mm, 30.5 mm, 31 mm, 31.5 mm, 32 mm, 32.5 mm, 33 mm, 33.5 mm, 34 mm, 34.5 mm, 35 mm, 35.5 mm, 36 mm, 36.5 mm, 37 mm, 37.5 mm, 38 mm, 38.5 mm, 39 mm, 39.5 mm, 40 mm, 40.5 mm, 41 mm, 41.5 mm, 42 mm, 42.5 mm, 43 mm, 43.5 mm, 44 mm, 44.5, 45 mm, 45.5 mm, 46 m, 46.5 mm, 47 mm, 47.5 mm, 48 mm, 48.5 mm, 49 mm, 49.5 mm, 50 mm.

Carbon fiberCNC machine

Machinable carbon fiberprice

Avient has a portfolio of carbon fiber composite products within our Glasforms™ and Gordon Composites™ product lines. These CFRP materials consist of thermoset continuous fiber polymer rods, bars and laminates used in a variety of applications that require superior technical characteristics.

Tags: carbon fiber sheet cut to size, carbon fiber sheet cutting, carbon sheet trimming, carbon fiber milling service, sheet made from carbon, carbon fiber sheet supplier, carbon fiber machining service, machining carbon fiber sheets, milling carbon fiber sheets, carbon panels cutting, cutting carbon fiber panels, trimming composite sheet, cutting carbon fiber, carbon fiber plate cut to any size, Machining CFRP, Drilling Carbon fiber, CNC carbon fiber sheets machining, CNC carbon fiber composites machining, cutting carbon fiber parts, machining carbon fiber composites, CNC machining carbon fiber parts

Our offer includes comprehensive services related to manufacture and machining carbon fiber sheet to specification (.dxf, .dwg, .pdf). We offer milling of carbon fiber sheets sized max 280x120cm and thickness from 0.5mm to 50mm (from 0.02 to 2 inches) . Product cutting follows with a milling machine to any desired thickness and accuracy up to 0.05mm (0.002").

Carbon fibermachining safety

Carbon fiber, sometimes referred to as graphite fiber, is formed by bonding carbon atoms together to form a long chain. Carbon fiber filaments can be woven to form a fabric or take permanent shape as a composite material when combined with a resin. Carbon fiber can also be chopped or utilized as a reinforcement for long fiber thermoplastic (LFT) composites depending on the application need.

Carbon fiber reinforced polymers (CFRP), or carbon fiber composites, are made by combining carbon fiber with a resin, such as vinyl ester or epoxy, to create a composite material that has higher performance properties than the individual materials alone. They are stronger, lighter and more durable alternatives for many applications traditionally made with wood or metal. With a typical tensile strength of 400 – 500 ksi and average density of 1.55 g/cc, CFRP composites can be up to 10 times stronger and 5 times lighter than steel.

CNC carbon fiber sheets machiningMachining carbon fiber sheets differs from machining metals, including aluminum, as carbon fiber conducts heat poorly and at the same time transfers little heat during milling. Therefore risk is higher due to overheating of the resin that provides bonding for carbon fibers and local damage to material undergoing cutting. At the same time, carbon fiber is a very demanding material as regards the tools used – CNC carbon fiber sheet machining rapidly blunts the cutting edge, requiring frequent tool replacement.Thanks to over 10-years experience in the field of carbon fiber sheet machining service, we deliver details and components free of any defects such as bulging, with smooth edges, sized perfectly to specification and with appealing aesthetic appearance.

Thanks to wide experience we offer carbon fiber trimming services of different carbon fiber elements purposed for industry, including for instance carbon fiber grippers, automated machine arms that require high precision and durable material (CFRP).

Carbon fiberCNC service

Machinable carbon fiberproperties

Our company does not provide services related to machining of carbon fiber sheets supplied by the client. We supply comprehensive services including CFRP cutting according to the client’s specification but using carbon fiber sheets manufactured by our company.

Inch metric thickness: from 1/64" to 2", e.g. .025" in, 1/32" in, 1/16" in, 1/8" in, 5/32" in, 3/16" in, 1/4" in, 3/8" in, 1/2" in, 5.8" in, 3/4" in, 1" in, 1-1/4" in, 1-1/2" in, 1-3/4" in, 2" in

Yes we do. We provide services related to any size threading in carbon fiber sheets. Our scope of services includes threading, as well as drilling and placement of steel threaded bushing.

Machinable carbon fiberfor sale

Yes we do. Our company also provides services related to large carbon fiber sheets machining and manufacture of elements up to 280 cm (110 inches) long.

Carbon fiber composites can be found in consumer goods, like archery bow limbs and sail battens. They are also present in automotive body panels, wind turbine blades and orthopedic external fixators. Transportation, consumer, healthcare, energy, infrastructure and construction are all industries that benefit from the advantages of carbon fiber composite materials.

Yes. We provide comprehensive services related to manufacture of carbon fiber sheets (or molded composites) and cutting and we deliver all works with a 4-axis CNC milling machine. We have in stock a large quantity of carbon fiber sheets of different thickness enabling us to deliver all orders promptly.

0086-813-8127573

0086-813-8127573