GEARWRENCH Premier Auto Mechanics Hand Tools and ... - tool brand chart

Whether you rely on carbide drill bits, inserts, cutters, end mills, or any other tool, you can increase their lifespan and reduce downtime with cryogenic treatment.

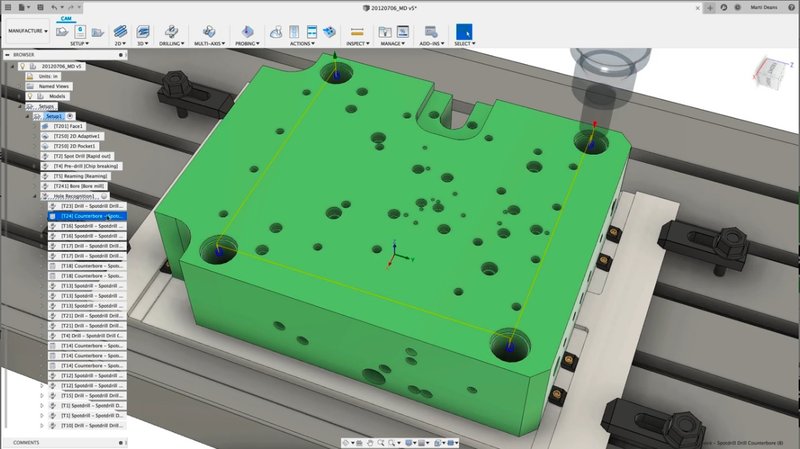

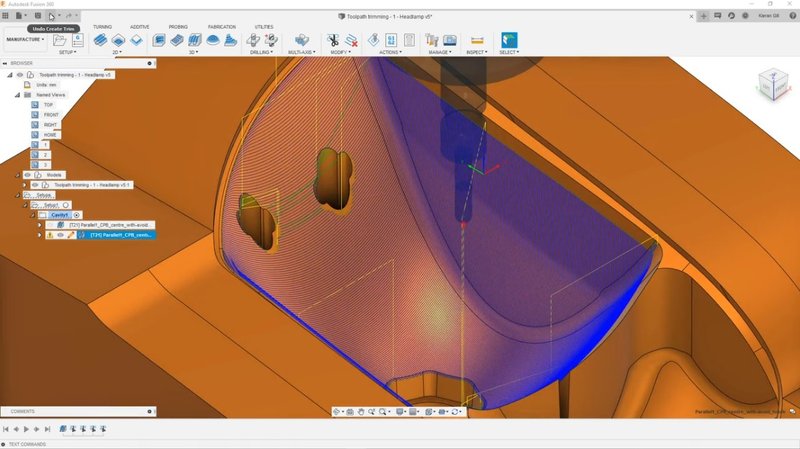

The Autodesk Fusion 360 Machining Extension expands the functionality of CAM programming tools inside Fusion 360 workspace. This extension is designed to prepare the model for machining. It allows for a flexible cost-effective way to make better use of your 5-axis CNC machinery and produce parts of higher quality.

You can take advantage of powerful modification tools to make global or local edits to toolpaths without wasting time on a complete recalculation. For greater flexibility you can edit modifications themselves.

Cryogenic treatment is a one-time process that involves cooling the metal to cryogenic temperatures (–238 °F or below) with the help of a cryogenic liquid or gas. Then, it can be heated back up to a higher temperature and allowed to cool naturally.

It might seem counter-intuitive, but carbide is both the hardest drill bit – up to five times harder than steel – as well as the most brittle. That’s because, when it comes to tools, hardness is just one of the factors that determines a material’s overall strength.

High-speed steel (HSS) is commonly used in drill bits and power saw blades because it’s affordable and capable of cutting through wood, plastic, and soft steel. HSS drill bits cut faster than other types of steel, which is where they get their name.

Most metal products are forged or cast at high heat, after which they must be cooled to room temperature. Traditionally, this was done by quenching them in water, but modern cryogenic techniques provide a more controlled treatment process.

With automated 3+2 machining you get the access to additional strategies and tool axis controls that can use the rotary axes of your CNC machine to drill and mill entire parts.

Cobalt drill bits have a recognizable gold color. Although it looks like a coating, it’s not, and is the result of a “baking” process that the drill bits go through. It may wear off with use, but this won’t impact the quality of the drill bit.

This is because the temperatures that your drill bits are subjected to when they’re first made has a long-term impact on the quality of the finished product.

They stay sharper longer than cobalt drill bits do, and they have a higher cutting speed. They can also handle higher temperatures.

Cobalt drill bits can be sharpened without losing their strength. They also have a relatively long lifespan, making them an affordable option despite their higher cost.

However, while high-speed steel is capable of many types of maintenance tasks, it isn’t suitable for more industrial uses, which is where other materials come in.

Drills are one of the most important items in any toolkit. Depending on your industry or product, your drills need to be able to cut holes in wood, plastic, metal, and more – all while adhering to precise measurements and quality standards.

Multi-axis collision avoidance Includes 4- and 5-axis collision avoidance, advanced tool axis smoothing, tool axis tilting limits, and more

4- and 5-axis simultaneous milling Includes 4-axis rotary, 5-axis steep & shallow, swarf, multi-axis contour, multi-axis flow, and more

CTP Cryogenics has over 30 years of experience in the field of thermal processing. We work with carbide tools of all kinds, using a proprietary treatment process that’s tailored to your specific use case and industry.

But the best drill in the world won’t be much use to you if its drill bits aren’t up to the job. No matter how powerful your drill is, what really determines its capabilities is the bit.

Since each tool has a specific concentration of tungsten carbide, it may take multiple tries to find the right treatment process for your drill bits.

The type of drill bit that you need depends on several factors, including the material that you’re cutting, but also the length of drill bit that you need. Longer drill bits can be more brittle and break easily, even if they’re made out of a strong material.

Let’s take a look at the hardness of each type of drill bit, as well as some of the things to keep in mind when choosing between carbide and cobalt drill bits.

However, you can’t simply use any sharpener on your carbide drill bits. You’ll need the right tool for the job, which in this case is a diamond-surface grinding wheel.

In this article, we’re going to take a look at the key characteristics of a drill bit – including the metal it’s made out of, its tip, and its coating – as well as how you can use cryogenic processing to make your drill bits stronger and longer-lasting.

That’s why they’re primarily used in automated equipment, and aren’t designed for use in hand drills and other manual processes where they can snap under pressure. You’ll find them in a range of industries, such as automotive and aerospace factories, where only the hardest drill bit tips will do.

We have multiple locations around the U.S., ensuring that you can get your tools treated in a timely manner. By having your carbide drill bits treated in advance, you can cut down on delays and downtime later.Contact us today to get a free quote and learn more about the process!

Then there’s carbide, which in this case is actually tungsten carbide and is a compound of tungsten and carbon. Carbide drill bits are often made out of steel with a carbide tip. They’re commonly used in industrial applications due to their superior strength. They can cut through concrete, masonry, tile, and more.

To learn the current price of the Autodesk Fusion 360 Machining Extension, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

3+1 and 3+2 axis positional milling Includes 4-axis wrapping of 2D toolpaths, align tool axis to view/surface normal, interactive tool axis tilt and turn

The Fusion 360 Machining Extension is an indispensible set of powerful tools for any enterprise employing CNC machining. The extension allows for workflow automation which helps the user speed up programming, eliminate repetitive tasks, and minimize possible errors. It greatly adds to your CNC machines’ performance and ensures production of high-quality parts.

Carbide drill bits are made out of tungsten carbide, although they often contain small amounts of other materials, such as cobalt, to reduce their reactivity with iron. You can usually find carbide drill bits in one of two forms: carbide-tipped or full-body.

Even the most high-quality drill bits are going to wear down after a while, at which point you have to decide whether it’s better to sharpen them or replace them. Due to the high cost of carbide drill bits, it’s probably worth your while to sharpen them.

2D and 2.5-axis milling Includes 2D adaptive clearing, pocket machining, face milling, slot machining, contouring, and more

Drill bits that are cryogenically treated have been shown to drill twice as many holes as drill bits that aren’t, before needing to be replaced. The treatment process changes the carbide’s microstructure, resulting in drill bits that are 7% harder.

Advanced multi-axis strategies and tool axis options allow you to drive the linear and rotary axes of your CNC machine simultaneously to improve surface finish, use fewer parts setups, and produce the most complex shapes safely and efficiently with automatic collision avoidance.

Automatic hole recognition & drilling (3-axis and multi-axis) Includes automatic feature recognition, machining templates, multi-axis drilling, tapping, thread milling, boring, and more

Or call 818-445-3030 to speak with someone now. Contact Us Form Name Email* PhoneIndustry How Can We Assist You?*PhoneThis field is for validation purposes and should be left unchanged.

This function allows you to measure features in-process with the probing cycles on your machine. You can verify dimensions and positions of critical geometric features, update tool wear parameters, and pause or stop your programs to address out-of-tolerance features.

If you don’t have a grinding wheel at your disposal, then it may be more cost-effective to hire a professional to do it for you. So while you can sharpen carbide drill bits yourself, it requires specific tools and you may need some training to get it right.

2-axis turning Includes face, profile (rough and finish), groove, thread, chamfer, part-off, part handling sub-spindles, and more

Carbide tips can drill through hard, non-metallic materials like masonry, while full-body drill bits are primarily used in automated processes.

Carbide inserts can be used to work with cast iron and steel, as well as bronze, copper, aluminum, and other hard or abrasive materials.

x86-based 64-bit processor (for example, Intel Core i, AMD Ryzen series), 4 cores, 1.7 GHz or greater; 32-bit not supported

Another option is to treat your drill bits cryogenically to reduce wear and make them last longer without the need for frequent sharpening. Although cryogenic treatment is known for its use in manufacturing, including the treatment of aerospace and automotive parts, it can be used to extend the life of cutting tools as well.

With CAD-based probing capability you can measure and improve the accuracy of complex surface geometry with a spindle-mounted probe. Intelligent part alignment automates the setup and machining of non-prismatic parts, like forgings and castings, thus helping save time and increase product quality.

Cobalt drill bits are made with a steel alloy containing 5-8% cobalt, so they can be used to cut into steel and other hard metals like cast iron.

This Applied Science video shows how you can do it at home with liquid nitrogen, but for best results, we recommend choosing a professional.

First, we need to understand how drill bits are actually constructed. Many drill bits aren’t made of a single element, but are made out of a steel alloy. Some drill bits are tipped or coated with a second material to make them stronger or more resistant to rust.

Other tools use carbide inserts, which are often triangular or diamond in shape, and are inserted into a tool made out of another metal, such as carbon steel. The benefit of this approach is that the tool is less brittle overall, and you can rotate the carbide inserts to expose a different edge when the cutting side becomes dull.

Titanium drill bits are usually made out of steel with a titanium coating, so they aren’t as strong as cobalt drill bits, and are liable to lose their coating over time.

Cobalt drill bits are ideal for when you need to drill through hard metals. They come in two grades: M35, which is made of 5% cobalt, and M42, which is made of 8% cobalt.

How do you know if you should use a carbide or cobalt drill bit? Although both types of drill bits have their uses, they can’t be used interchangeably, so it’s important to use the right one for the task at hand. Let’s take a look at the pros and cons of each:

Hardness refers to the surface of the material – essentially, how easy it is to scratch or dull its surface – while brittleness refers to how easy it is to break. So while carbide drill bits are very hard, and can cut through some of the most difficult materials, they’re also brittle and can break if not used properly.

The function simplifies the drilling and milling of complex, feature-rich models with a range of intelligent toolpaths that can safely and efficiently process an entire part for faster CAM programming.

Because they can handle temperatures as high as 1100 °F, cobalt drill bits can be used in high-heat settings. The higher the percentage of cobalt, the more heat-resistant it will be; at the same time, a higher percentage of cobalt means it will be more brittle.

In some cases, the drill bit will be made out of a less brittle material, and only the tip will be made out of carbide. That way, you get the hardness of carbide on the drilling surface, with the stability of a less brittle material to prevent the bit from breaking.

0086-813-8127573

0086-813-8127573