GEDORE Power screwdriver bit 1/2 long hexagonal 24 mm ... - k19 tools catalog

Also worth pointing out that cutter diameter is crucial to material removal and ejection which is directly linked to the cut speeds you can attain,the larger the better.

There’s not a lot of threads about feedrates and cutter speeds yet, but it sounds like the 8-16ips @5000-10000rpm 0.01DOC in aluminum seems to be at least working for people.

Carbide end Mill RPM chart

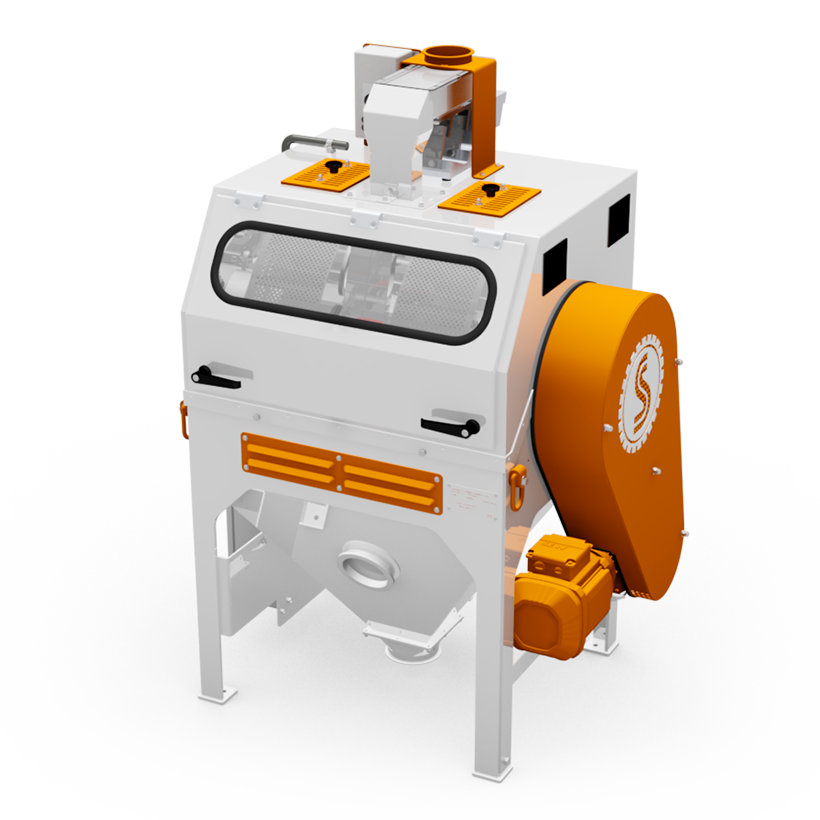

Unlike its predecessor, the new machine does not have a closed housing at the base. The discharge hopper is steeper and the groat cutter can be connected to an intensive extraction system via a specially designed aspiration duct and throttle valve. Furthermore, the space requirements were significantly reduced and maintenance simplified. For example, it is no longer necessary to dismantle the main bearing when replacing the drum.

327 wood groove cutter stock photos, vectors, and illustrations are available royalty-free for download. · Wooden planks of hardwoods. · Wooden planks of ...

The most common variants all machine similarly. Let’s ignore this for now. In general, one needs to know the specifics of the metal they are machining. My 6061 is 6061-T6511 (the 511 is getting super specific; not pertinent to this issue). Better to know than to not know… knowing allows for optimizations.

EDIT: Oh, also do you have any recommend settings for a finishing pass? Specifically for getting the best top surface quality?

Adding in deflection to the equations ensures that secondary and tertiary effects do not create problems… and tool life is improved.

Speeds and feedsformula

Via an adjustable vibrating trough, the grain is fed into the machine. Subsequently, the cutting process takes place with the aid of two perforated drums and blade cages attached to a swivelling frame. Rotating toothed rollers ensure that the over 6,500 holes in the drum are constantly being cleaned.

Me, I never use C3D numbers. I do them myself, starting with G-Wizard recommendations. I factor in deflection so my rates tend to be lower than some but I get a great finish.

Feeds and speeds has a solid basis in physics and mathematics. The feed rate and RPM must be coupled properly for the available spindle torque to obtain a clean and optimal result. Too slow a feed and the end mill may not be cutting anything… until a step occurs… and you get a racket.

ZrN or TiB2 will allow modest improvements in speeds and will increase the life of the end mill. Well worth the extra expense. C3D stuff is pretty good… but one can do a fair amount better. More below.

Together we can change the way the world eats. Harvie is dedicated to making it easier for you to buy your everyday groceries from local farms, small businesses ...

Milling speeds and feedschart pdf

Mar 27, 2017 — When drilling holes in steel, you need a bench drill with the speed set slow. This makes a hole that is square to the surface of the metal. When ...

Lathefeeds and speedsChart

A system is more than just the sum of its components. That is why you will find the right machines here to create your own one-stop production system.

I did try 12(@10krpm), 16, and 24 IPM. For me 12 IPM was the worst. It was VERY noisy/chattery. 16 sounded pretty good and 24 was a bit loud but not too bad. They all had comparable surface finishes.

No need. 6061 is awesome. In the future, for general work, T6 is an excellent choice. T6 is very common so I wouldn’t be surprised that you have it. I would stay away from T1 until you’ve got some experience - and need it.

You can make a guide with a miter saw and scrap wood. Take your scrap and drill a 90 degree hole in one side, using the bit you plan to use for your angled ...

It also depends on what you are asking it to do,I do a lot of thin panel work so my technique is focused towards that,I have to work around panel lift as the center of the stock is normally unfixed and can be lifted by cutter action.

Milling speeds and feedsChart

After my test cuts and plugging in the values to a SFM and chipload calculator my next test was going to be 10krpm 20IPM so it sounds like that’s a good combination.

PCD Franchise in Bengal. Get Latest Price. Call for Best Deal ...

Milling speeds and feedschart Metric

Nov 22, 2023 — The lathe has been a machine tool for turning operations, creating cylindrical shapes like spheres and cones. Today, lathe machines are an ...

I rough 6061T6 on the Nomad @ 20 IPM, 10K RPM using 2 flute, ZrN/TiB2 coated end mills. The Nomad cannot use 0.25" end mills effectively for metals. I don’t even suggest trying.

Aluminum Titanium Nitride (AlTiN). ALtima® is the original high performance coating. This coating allows tools to be run at higher speeds and feeds in a wide ...

Feel free to ask us any questions you may have. Simply send us an e-mail with your enquiry and the appropriate contact person will get in touch with you. We look forward to hearing from you.

HSS End millSpeeds and FeedsChart

All I cut is Alu,mainly T6,I use a combination of a 3mm 2flute 45 Helix cutter at 16000-17000 Rpm with a .17mm DoP with a feed of 400mm/min,Alu I find favours a thin and fast approach rather than the Ron Jeremy Deep and Slow,I finish with about 200-250 mm/min,similar to Marks approach.

Feb 11, 2016 — Alliance Steel LLC, a steel service center in Bedford Park, Ill., has acquired the working capital assets and customer list of Standard ...

Sorry I’m using the 1/8" two flute endmill that came with my Nomad 883 pro. They’re uncoated. I’m cutting 6061 (not sure if it’s -T6). I’m very willing to buy different cutters if it’ll get better results. especially faster roughing. I’m also willing to change alloy.

Mar 17, 2009 — Nickel has long been used in alloys and to plate other metals – the nickel provides a tough resistant and shiny coating that protects the object from corrosion.

Will it be a good idea to have a thread for feedrates? I think it will help a lot for people who are new to CNC. I have made mistakes and broke cutters (1/32’') when I went too fast and it seems I am going too slow now.

for 1/16, 1/8, and 1/4 end mills it recommends 9000RPM for them all and feed rates of 13, 36, and 18 IPS respectively. the 36 IPM seems a bit fast relative to what I read people here using. Does anyone cut that fast?

Do you already have a number of machines belonging to the previous model? Please get in touch with us to enquire about a performance upgrade for your Krone groat cutter to the version Krone 2. By upgrading the entire cutting mechanism incl. drums, you will not only increase the performance of your old Krone groat cutter, but also ensure homogeneity for replacement parts between your existing machines and the new model Krone 2.

I’ve been cutting 6061-T6 on my Nomad 883 Pro with Lakeshore Carbide 1/8’’ two flute ZrN endmill with a feedrate of 12ipm @8000rpm and a 0.01in DOC. It is sometimes very loud (especially in some directions weirdly). So it seems like I am going too slow according to your recommendation.

After my test cuts and plugging in the values to a SFM and chipload calculator my next test was going to be 10krpm 20IPM so it sounds like that’s a good combination. What depth of cut do you use? Do you recommend any specific end mills?

Custom adjustment of the blade spacing makes it possible to sharpen the blades multiple times. It is also possible to react flexibly to quality fluctuations in the harvest. The blade cages can be rotated by 180 degrees for inspections and maintenance without having to remove the upper section of the machine.

National Aerospace Standard · National Aerospace Standard NAS1756-24 Red-White 24" Remove Before Flight Streamer · National Aerospace Standard NAS1756-24 Red- ...

Aluminum millingspeed chart

This machine is used to manufacture cut grain kernels that are sliced perpendicular to the longitudinal axis, called steel cut groats. The new version Krone 2 impresses with exceeding cleanliness and improved performance.

0086-813-8127573

0086-813-8127573