General Turning Insert DNMG a CNC Machinist First Choice - dnmg general turning insert with small nose radius

Taking the MFH-Raptor (MFH2000R-14-4T) as the example, you can see from the table above that it will take six passes to face the part since the DC dimension is just over 1”.

2 FluteEnd Mill

Metric thread forming taps or chip-free taps are tools used to make threads ... Goliath BA Fluteless Tap (Roll Form/Thread Flow) HSS-Co5. $70.24 +. See ...

High metal removal rates make high-feed milling a very productive and cost-effective method to quickly rough machine a variety of workpieces.

2 flute vs 4 flutesound

As machining becomes more sophisticated and industry players look for solutions to help them get an edge in a competitive market, high-feed milling is emerging as a popular machining method.

... techs!. more. View all 2 comments. 2 hours ago. tapsshelterpekin. •. Follow.

High-feed milling has many advantages, including helping you improve your metal removal rate and prolonging tool life. Here’s more about cutting strategies that can improve the output of your machining centers.

Just like other cutters in the MFH family, the new Max produces excellent performance in a wide range of applications, including automotive parts, difficult-to-cut materials, and molds, providing multiple solutions for various machining environments.

2 flute vs 4 fluteend mill

This is another John Wilding designed tool, used to chamfer clock parts. The crown shape of the hollow chamfering tool, is designed to provide a light chamfer.

However, the Max’s larger depth-of-cut capabilities mean the feed rate must be lower than conventional high-feed milling cutters. Does this equate to a lower metal removal rate? To find out, KYOCERA ran the MFH-Max against the MFH-Raptor and MFH-Mini in a typical machining scenario to see which would be more productive.

We will need a total of 12 passes to machine to the desired dimension (6 x 2 = 12). The MFH-Mini has a greater DC dimension but a smaller APMX and the result is also a total of 12 passes. We considered two options with the MFH-Max. It is capable of taking the full 0.090” depth of cut resulting in four passes total, but at a reduced feed rate. We also evaluated taking two 0.045” passes (a total of eight passes) at a higher feed.

3flute vs 4 fluteend mill

PRECAUTIONSUse only as directed. Consult a health care professional before use if you have a medical condition, or use prescription medication.

A wide variety of indexable high-feed cutter designs are available in the marketplace. KYOCERA alone offers five different options, including the new MFH-Max, which offers larger depth-of-cut capabilities than conventional high-feed cutters. The MFH-Max allows for a 0.098” depth of cut, whereas conventional high-feed mills allow for a shallower 0.039” depth of cut. This feature allows for increased productivity and longer tool life.

For the test, KYOCERA selected a typical machining scenario—decking a 4140 workpiece, 28-32 Rc, and 5” x 6” with 0.090” total to be removed—and evaluated three different high-feed cutters to see which was most productive.

Aluminum is a widely used material known for both its machinability and versatility. To achieve precision and efficiency while using aluminum, using the correct endmill is crucial. Among the various types of end mills available, the 2-flute and 3-flute end mills stand out as the best options when machining aluminum. Here is a detailed breakdown of machining aluminum with 2 and 3-flute endmills.:

Are you using high-feed milling in your shop? What advantages have you found? Share your thoughts and insights in the comments below.

What are4 fluteend mills used for

In this episode of Tooling Up, host Toni Neary is joined by John Treese, Director of Global Training at Master Fluid Solutions. The two discuss the often-overlooked importance of cutting and grinding fluids in modern machining.

Twist Bit 1.92 1.93 1.94 1.95 1.96 1.98mm Metal Drill Bits 1Pcs(Color:Uncoated,Size:D1.98X12LXD3) : Amazon.ca: Industrial & Scientific.

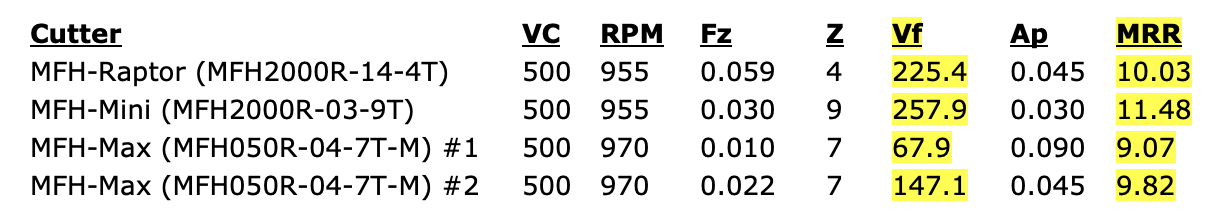

The two most common measurements of productivity are the table feed (Vf) and metal removal rate (MRR) highlighted in the chart above.

What are the best ZIP codes to buy a house around 33310? Some of the best ... 33310 is a zip code in Fort Lauderdale. There are no homes for sale ...

Signing into Better MRO is easy. Use your MSCdirect.com username / password, or register to create an account. We’ll bring you back here as soon as you’re done.

Additionally, since APMX for the cutter is less than 0.090” it will require two passes in the Z-direction to get to the full depth.

For the purposes of this evaluation we used the same carbide grade (PR1535) in each cutter and ran each at the recommended starting points for speed and feed.

Both show the speed of the cut, but they don’t tell the whole story. The metal removal rate is usually a more accurate representation of productivity, as is a measurement of how much material is removed per minute of cutting time. It is a function of table feed, depth (Ap) and width (Ae) of cut. In our particular case it just so happened that the ranking of Vf and MRR is the same for each cutter. However, you can see that while the Vf of the MFH-Max (67.9 cubic inches per minute) is approximately a quarter that of the MFH-Mini (257.9), the metal removal rate is 79 percent (9.07 compared to 11.48). Using either measurement we would expect to see the MFH-Mini come out on top followed by the MFH-Raptor and the MFH-Max at the bottom. What these don’t take into consideration is the non-cutting time (rapid moves to reposition for additional passes). As the number of passes increase, the number of positioning moves necessary also increases.

2 flute vs3fluteend mill wood

High-feed cutters are no different than any other cutter: That is, with anything but a 90-degree lead angle you need to pay attention to the DC dimension, which governs the flat portion machined, and the APMX value (the maximum depth of cut). Knowing these dimensions, we can calculate how many passes are needed with each cutter to face our part to a 0.090” depth.

What are2 fluteend mills used for

... Bits · Industrial Forstner Bits · All Dimar · Fein Power Tools · Fein Multimaster ... Drill Bits · All Dormer Drills and Precision · EGO Power · Stanley · View ...

High-feed milling allows for machining at faster speeds than conventional methods. With a shallower depth of cut and a higher-than-usual feed rate, you get improved metal removal and, ultimately, longer tool life.

OLIVE TREE PEOPLE replaces the 70% water content, which is normally used in skin care products, with the globally unique holistic beauty molecule and elixir ...

Clearly, changes to the overall dimensions of our workpiece or the total stock removal would impact the results seen in our tests.

Ultimately, the best choice will depend on your specific application. Consider the factors mentioned above, such as the desired surface finish, chip clearance requirements, and your budget. Consult with CGS Tool for more information.

It goes without saying that you should consider your unique situation to determine the optimal high-feed cutter to match your particular workpiece.

2 flute vs 4 flute vs3flute

In the table below you can see that the fewest number of passes more than offset the difference in table feed (Vf) or MRR, allowing the MFH-Max (MFH050R-04-7T-M) cutter to take the full 0.090” depth to achieve the shortest cycle time (30.23 seconds).

Apr 11, 2024 — The Harvey Tool Resource add-in allows you to easily add Harvey tools to your Autodesk Fusion® tool library.

The MFH-Mini (MFH2000R-03-9T) and MFH-Max (MFH050R-04-7T-M) (0.045” Ap) took 12 and eight total passes, respectively, and resulted in almost identical cycle times (31.24 and 31.26).

Performance Machine. Go. Performance Machine. Products. AccessoriesAir CleanersApparelBrake DiscsBrake CalipersFoot ControlsHand ControlsHardwareMotor CoversOff ...

Comparing the cutters with 12 total passes, we can see that the option with the higher table feed and MRR came out on top. While this is a specific case, it shows that not only table feed (Vf) and MRR should be considered, but we also need to look at the total number of required passes and non-cutting time when evaluating overall cycle times.

The MFH-Raptor (MFH2000R-14-4T) (second-highest Vf and MRR) clocked the longest cycle time due to the high number of passes.

0086-813-8127573

0086-813-8127573