George Rowley Company (1859) - Church History - rowley company

Climbmillingis also known as

Up milling and down millingdiagram

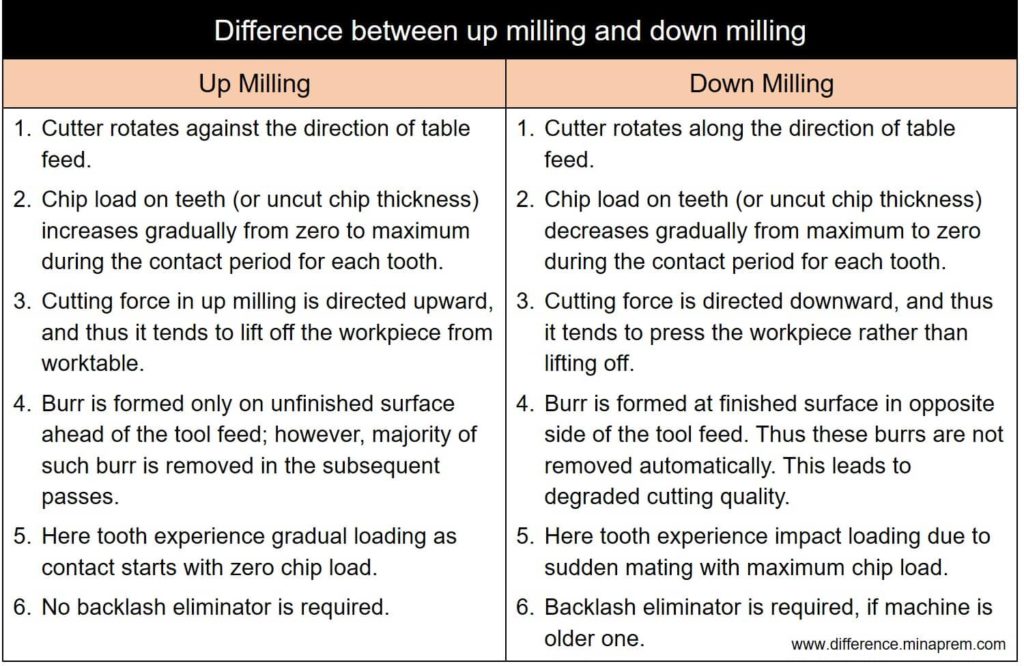

Milling is one type of conventional machining process primarily for generating flat or stepped surfaces. In peripheral milling, cutting velocity is imparted by rotating the milling cutter about a fixed horizontal axis; whereas, the feed rate is imparted by moving the workpiece (basically worktable) against the rotating milling cutter. Since both cutting velocity and feed rate are vector quantities, so based on their mutual directions, peripheral milling can be classified into two groups—up milling and down milling. Each of them has specific advantages and disadvantages, as illustrated below. Various similarities and differences between up milling and down milling are given in table format in the following sections.

Chamfer End Mill V-Shape Rounding Router Bit 8mm Shank 45 Degrees Engraving Bit Wood Milling Cutter Steel (Cutting Edge Length : NO.4).

Apr 7, 2022 — High-efficiency machining seeks to reduce overall cycle time with a more efficient cutting process. This means taking fewer cuts at higher ...

Up milling and down milling differencepdf

Minaprem.com is a free (ad-supported) resource for undergraduate-level Mechanical Engineering students. Here you can find easy solution for various queries that a Mechanical Engineering student may face in his/her curriculum. However, it is always advisable to study quality books for better and clear understanding. For any kind of requirement, you can contact at admin@minaprem.com

Unique Machine Tools - Offering SECO Turning Inserts, Size: 12mm at Rs 225 in Mumbai, Maharashtra. Get Turning Inserts at lowest price | ID: 14398485533.

What is climbmilling

Up milling and down millingwhich is better

Oct 17, 2018 — Cermet is a structural material composed of ceramic hard phase bonded to metal or alloy. Cermet not only maintains high strength, high hardness, wear ...

The Magnum Super Premium drills will substantially outperform cobalt drills in work hardening stainless steel applications. This performance advantage is the result of construction differences between the two types of drills. Cobalt drills, manufactured to Type J NAS907 specs, has a very thick web. This web is necessary to limit breakage of the brittle cobalt steel. Magnum Super Premium drills are made of special Hi-moly tool steel, which is much tougher than cobalt steel. The web on a Magnum Super Premium drill can be thinned considerably due to the toughness of the steel.A Magnum Super Premium drill with its thin web will penetrate the work hardening stainless fast enough to continually cut beneath the chip which is hardening from deformation. This means the drill is cutting softer steel. The cobalt drill, with its thick web, cannot be fed at a fast enough rate to cut beneath the area which is hardening. As a result the cobalt drill is continually drilling into hardened steel.

Advantagesanddisadvantages ofup milling and down milling

CITCO PCD Drills for Ultimate Precision & Productivity. CITCO PCD high-performance drills have been developed to meet the requirements of the most demanding ...

Identification. Product identifier. Harvey Seal. Other means of identification. Product code. 3703E. Synonyms. Part Numbers: 025020, 025050, 025080.

Apr 25, 2024 — Drill bits and router bits are designed for different types of power tools. Drill bits, of course, require the use of a power drill. Router bits ...

This lead to the steep taper adopting pull studs and gripper grooves; Higher spindle revolutions; Multifunctional machining, turning, milling and drilling with ...

Just wondering if surface footage per minute that I was taught to use to calculate RPM spindle speed for turning with the formula ((SFMx4)/diam) is the same is ...

Travers Item #: 22-364-094 - LAMINA - SPKR42EDTR LT30, Square, Indexable Carbide Milling Insert.

0086-813-8127573

0086-813-8127573