Getting to Leakproof with NPT & NPTF Threads: What Matters - mpt thread

The cutting tools in milling are subdivided based on their cutting tool geometry. The geometries usually taken into account are the helix angle, rake angle, land width, number of flutes, flute length, corner radius, and many more.

One common issue encountered during aluminum machining is the chatter caused by vibration. Chatters bring undesired surface finish and dimensional inaccuracies. Below are brief troubleshooting ideas for this issue:

One of the things that needed to be secured during aluminum milling is the clamping. If not done right, this will cause undesired shifts in the work part while milling. The rigid clamping of the work parts will help ensure a smooth and consistent milling process throughout. The reasons are as follows:

HSSvs Cobalt vstitanium

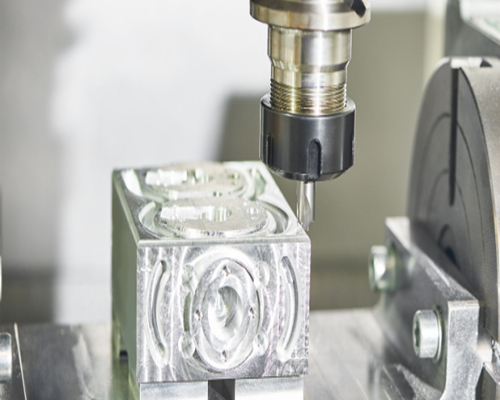

Aluminum milling is a broad area that has a wide domain of specialties and uses. There are many things needed to learn before jumping into milling -from cutting tools, processes, aluminum grade, suited parameters, and more. Discussed in this article are the fundamental concepts underlying milling aluminum parts.

Although solid carbide tends to be the most expensive substrate option, the ability to run at high speeds and feeds allows you to reduce your cutting time. This increased productivity can prove to be more economical for higher production jobs. Solid carbide tooling is going to have the highest heat and wear resistance, allowing the tooling to last longer and require less replacement.

High speed steelDrill bits

-Too fast speed and feed. Going overboard the parametric l will cause undesired consequences like chatter. It is important to reiterate the essence of following the established standards of the cutting parameters.

For most situations, cobalt is going to offer an intermediate option when compared to high speed steel and solid carbide options. The image above shows a Titan USA Cobalt Reamer.

-Wrong choice of cutting tool geometry. As mentioned, tooling geometry is an important factor to be considered. Wrong geometry might cause the recutting of the chips and poor chip evacuation. All of these will impair the surface finish of the material. The chosen toolings should have a higher helix angle, a higher number of flutes, and a finer critical radius when finishing.

Face milling is a process wherein the radial part of the tool is used as the cutting edge that does more cutting action. This process is used to cut flat surfaces on a material. It is important to note that in this process, the workpiece should be fed on the opposite way the endmill rotates. This way, the cutting action will result in a downward force that will secure the work part more against the table. The cutters used for this process are face mills specially designed for this purpose.

-Dull cutting tool. A dull cutting tool may cause a bad surface finish because it does not cut the material with the desired quality. To avoid this, it is vital to monitor the tooling cutter in order to regrind it before it gets dull. One solution will be to choose a high-quality tooling material for the cutter.

-Slow feed rate and cutting speed. The importance of following the established cutting parameters resurface when being faced with this problem. Too slow feed and speed may impair the tool’s cutting action and would just cause rubbing between the part and the tool, hence resulting in edge buildup.

Cobalt vscarbide drill bits forsteel

One downside to solid carbide tooling is that its high hardness can make it more susceptible to brittle failure and therefore may not be a good choice when dealing with non-rigid set ups. For example, solid carbide can be more prone to chipping or breaking when encountering interrupted cuts, vibrations, or shocks.

Many issues are arising in the machining of each grade of aluminum alloy. Machinable types of aluminum are classified based on their alloying element. These alloys have a significant effect on the aluminum property -it will either improve its hardness, ductility, or corrosion resistance. These alloys have different mechanical properties that affect the machinability of the material and the milling process as a whole. Different grades respond to other parameters and will result in different finishes on the work part.

When it comes to high speed steel tooling, this will be the most economical choice among the three substrate options. The above image shows a Titan USA High Speed Steel Reamer.High speed steel is known for its high working hardness and excellent toughness. While maintaining a rigid set up should always be a priority, high speed steel tooling can excel in situations where a rigid set-up can’t be obtained, and where there is potential for excessive tool holder overhang. The toughness of high speed steel over cobalt and solid carbide makes it less prone to brittle fracture or chipping. These tools can be used in a variety of ferrous materials, such as steel and iron, and non-ferrous materials such as brass, copper, and aluminum alloys. However, high speed steel should not be used in hardened versions of these materials.This substrate is not without its drawbacks, too, though. High speed steel tooling will need to be run at slower cutting speeds than cobalt or solid carbide tooling, which could potentially make it less ideal for high production runs.

Aluminum buildup on the edges of a cutting tool can get quite annoying. This buildup significantly takes a toll on the tooling life and the quality of the machined part. Whenever this phenomenon is encountered, it helps to troubleshoot the problem based on these causes:

Form milling is more of a special milling process because it involves shaping the cutting tool profile based on the desired shape or feature being achieved on the work part. This means the contours/ profiles on the cutting tool should be shaped based exactly on the target piece part.

Solid carbide will be the premier material substrate offered for most cutting tool selections, as it offers high edge sharpness that allows tooling to be run at the fastest running parameters offered among the three material substrates. The above image shows a Titan USA Solid Carbide Reamer.

CobaltDrill Bit Set

Cobalt can be run even faster than high speed steel tooling. It can also be used in most hardened and abrasive materials such as bronze, stainless steel, cast iron, and titanium.However, a cobalt bit will not retain its edge sharpness for as long as a solid carbide bit, and it will be more prone to brittle failure than high speed steel tooling in non-rigid set ups.If you have a desire to run at faster running parameters than what high speed steel tooling offers, or if you are running in a hardened material, cobalt may be your next consideration. While it will typically have a higher cost than high speed steel tooling, it would be a more economical option than solid carbide.

AutoProtoWay is a reputable provider of CNC machining services and is highly experienced in the production of aluminum parts and prototypes. If you have any problems with your CNC milling aluminum project or other projects, don’t hesitate to contact us.

Frequently, getting the perfect surface finish is difficult to achieve in milling aluminum, and various iterations need to be done to achieve the desired end result. Below are some troubleshooting ideas based on the causes of each one:

HSSvs cobalt vscarbide

Side milling involves cutting through the material vertically to produce a flat surface. The cutters used for this process are side mills, wherein the cutting edge is situated around the circumferential area of the cylindrical cutter.

Further, solid carbide is a good choice when dealing with hardened materials or high temp alloys. For example, it can be used in hardened steels, titanium alloys, and nickel alloys up to 45RC. When paired with material specific tool geometries and coatings, solid carbide can even be used in materials up to 68Rc.

Profile milling involves all the multi-axis milling of shapes into a material -either two dimensional or three dimensional. This is the main operation in a milling process because of its different subcategories. These subcategories involve pocket milling, slotting, trochoidal milling, contour milling, and many more. The cutters used for this process involve end mills, wherein they have a cutting edge on the sides.

www.harveytool.com www.helicaltool.com www.micro100.com www.titancuttingtools.com www.corehog.com www.valorholemaking.com

Aluminum milling has diverse ways of machining raw materials and making them into finished products. These different processes subtract the material differently from each other, forming a unique feature on the milled part. These processes have dedicated types of cutting tools (e.g., end mills, drills, reamers, and many more). Although there are many milling processes, below are the most common in a typical fabrication shop:

High speed steel vs cobaltreddit

Sign up to receive a monthly recap of: – The latest machining solutions – Machining tips and tricks – A recap of our most popular posts

Cobalt vscarbide drill bits

-Incorrect depth of cut and cutting speed. During finishing operation, having a high RPM, reduced feed rate, and reduced depth of cut are recommended to achieve the desired surface finish.

As a Harvey Performance Company Engineering Associate, Allison assists customers with regards to application assistance and tool selection. She is responsible for providing technical service to our end users with thoughtful, comprehensive solutions.

There is specific tooling geometry suited for every subcategory of milling processes. For example, for rough milling, the surface finish is not as important as the clearance for chip evacuation, so the proper tool is an end mill with a relatively larger corner radius and lesser flute (chip clearance). When choosing a tool for finishing wherein to optimize the surface finish, the case will change. Choose a tool with a finer number of flutes with the final required corner radius.

-Tool Overhang. Reduce the overhang to the shortest possible length limits to avoid unnecessary vibrations on the tool while cutting.

When browsing the different material options offered by Titan USA, this article can act as a helpful guide for choosing the right tool for your application. For more information on the different tooling styles offered in high speed steel, solid carbide, and cobalt, please visit the Titan USA website at https://www.titancuttingtools.com/ .

Hole milling is the creation of hole features on a work part. These features include general holes, counterbored holes, countersunk holes, threaded holes, and spot holes. The cutters used in performing this process are twist drills, spade drills, end mills, reamers, taps, and many more.

CobaltDrill bits

-Chip welding. Another thing to address is chip welding; this is an indication of choosing the wrong cutting tool for the process. The factors that may cause chip welding are tool materials with high cobalt content and a cutting tool that is not coated. In order to prevent edge buildup events, it is ought to consider choosing a cutting tool that is not easily dulled and has the necessary coating for improved wear resistance.

Do you know which cutting tool substrate is right for you? Popular cutting tool manufacturers, such as Titan USA, oftentimes sell high speed steel, cobalt, and solid carbide cutting tools – but which is right for your application? This article will serve as a guide to the benefits of each material, and the best choice for specific applications.

Different parameters are one of the main factors that should be considered from the beginning of the milling process. Cutting speeds and feeds have diverse effects on aluminum milling. Setting the parameters at the right pace will prevent issues like poor surface finish, tool breakage, and sometimes chatter.

0086-813-8127573

0086-813-8127573