Grade 10 Tungsten Carbide Ball Bearing (Ea) - tungsten carbide ball

Addressing Difficult-to-Machine Materials, such as Inconel or titanium, requires strategic tool selection. Opting for a tool with a lower helix angle becomes necessary to achieve cleaner cuts and enhance tool longevity in the face of these notoriously challenging materials.

Speeds and Feedschart

Simplified, it involves the lead of the screw (L), the circumference (C) calculated from the screw’s diameter, and the radius (rm) of the screw thread or gear. Measure the lead as the distance the nut moves in one screw revolution. Find the screw’s radius (rm) by measuring its diameter and multiplying by pi. 重试 错误原因

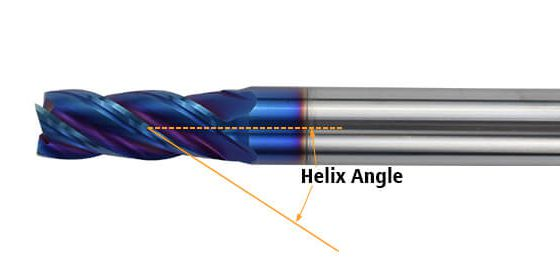

Picture a right triangle formed by unwinding a single turn of the helix, resembling the circumference of a circle with a diameter (d) equal to the screw’s diameter. The helix angle is the angle between this circumference and the pitch of the helix.

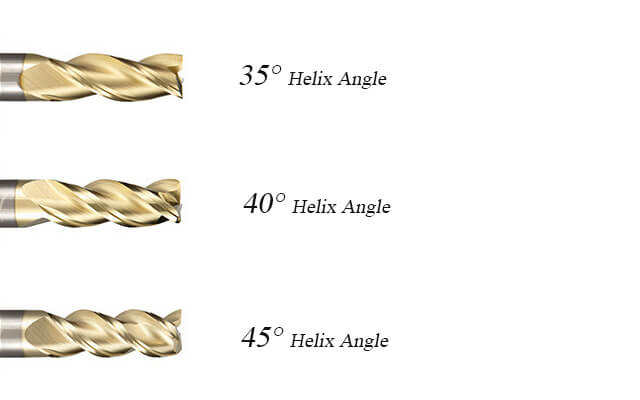

Cutting tools with helical flutes, such as helical end mills and drills, have cutting edges that line up with the helix angle of the tool. Helix angles for end mills typically span from 12° to 60°, while most activities are best balanced at an angle of 30°–40°. Taking into account a number of variables, this range guarantees peak performance. The efficiency of a cutting tool is greatly affected by even small angle alterations, which emphasizes the need for manufacturing specialists and operators to understand these impacts.

Spindle speedformula

In the scenarios of Pocketing and Slotting, the primary considerations revolve around tool rigidity and effective chip removal. Opting for a moderate helix angle provides a balanced solution, offering both stability and efficient evacuation of chips.

The influence of the helix angle extends to Tool Longevity, especially when contending with abrasive materials. Striving for an optimal helix angle becomes crucial in ensuring an even distribution of wear, potentially extending the life of the tool.

Feed rateformulafor turning

In High Feed Rate Operations, where rapid chip evacuation is vital, especially in softer materials, a higher helix angle proves advantageous. This facilitates swift chip removal, enabling uninterrupted and expedited machining processes.

Tools with low helix angles prove effective for minimizing chipping in hard metal materials, which include steel, cast irons, and easily machinable stainless steel. Additionally, synthetic materials like epoxy-based synthetics, fiberglass sheets, and abrasive plastics exhibit enhanced machining results when coupled with low-helix tooling.

The helix angle denotes the angle formed between the helix and an axis line along the exterior of the circular cylinder or cone, measured in degrees. This angle differs from the lead angle, which is measured concerning a line perpendicular to the axis. Notably, the helix angle is the complementary angle of the lead angle.

Feed rateformulafor milling

When dealing with Thin-Walled Components, machining operations can induce wall deflection. Employing a cutter featuring a heightened helix angle proves advantageous in reducing lateral forces, consequently minimizing the potential for deformation in these delicate parts.

Moreover, opting for a cutter with a variable helix angle proves advantageous in high-performance machining scenarios. Particularly beneficial for challenging-to-machine materials like stainless steel and heat-resistant superalloys, these cutters deliver superior cutting performance and boast an extended tool life. Consequently, they emerge as the optimal choice for even the most demanding machining applications.

Cutting speedformulaPDF

Feedformula

On the other hand, cutters featuring a higher helix angle are well-suited for softer materials such as aluminum, copper, and plastics.

In tasks demanding High Precision, controlling vibrations becomes imperative. Choosing a lower helix angle can often effectively mitigate vibrations, ensuring a smoother finish—particularly crucial when dealing with hard materials or intricate geometries.

A helix can be succinctly described as a form of three-dimensional curve that wraps around a straight line, commonly encountered in various aspects of everyday life. Examples include screws, helical gears, and worm gears. Additionally, helices can be observed in springs (such as those in weighing scales), the suspension systems of bicycles or cars, and even in clickable ballpoint pens.

Although there are application-specific variations, a 30°–40° helix angle is generally recommended for end mills due to its adaptability. Understanding these subtleties is essential to efficient machining. By comprehending the effects of varying helix angles, operators of machines can adjust tools to achieve the best outcomes in a variety of applications. This useful information improves machining efficiency and emphasizes how crucial it is to customize helix angles for particular applications.

Distinct materials call for varying helix angles. For instance, successful outcomes with hard metals necessitate low helix angles, whereas softer metals thrive with higher helix angles. Consequently, the choice of the appropriate helix angle should be contingent on the specific material undergoing the milling process.

Millingspeeds and feedsChart

In the intricate world of machining, the helix angle emerges as a critical determinant of success. Its profound impact on-chip control, vibration, and power requirements shapes the very essence of machining performance. Selecting the ideal helix angle for cutting tools is an art, with considerations spanning a range from 12° to 60° and common recommendations falling within 30° to 40°. High helix angles usher in advantages like refined surface finish and effective chip evacuation, while low angles fortify cores for formidable material removal rates. Precision in helix angle choice, tailored to applications and materials, unveils the delicate equilibrium between advantages and drawbacks, paving the way for superior machining outcomes.

Cutting speedformula

Apply the tan-1 function for the inverse tangent, which yields the angle in radians. This practical approach mirrors various mechanical applications of helix angles, particularly concerning screws. Employing this method ensures an accurate helix angle calculation for diverse engineering applications.

Determine the spindle speed (RPM) and feed rate (IPM) for a milling operation, as well as the cut time for a given cut length. Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth, such as an end mill or face mill. Calculations use the desired tool diameter, number of teeth, cutting speed, and cutting feed, which should be chosen based on the specific cutting conditions, including the workpiece material and tool material. Learn more about Milling.

In the context of Deep Hole Drilling, ensuring efficient chip evacuation holds paramount importance. Elevating the helix angle proves beneficial in facilitating improved chip removal, thereby mitigating the risk of jams. This streamlined evacuation process also serves to minimize heat generation, which could otherwise lead to tool wear or damage to the workpiece.

When it comes to end mills, the choice between high and low helix angles can significantly impact machining outcomes. Let’s delve into the advantages and disadvantages of each to help you make informed decisions for your machining needs.

The performance of machining operations is greatly influenced by the helix angle, especially in helical end mills and other cutting tools. This geometric characteristic has a major impact on power needs, vibration, and chip control. In particular, the angle determines how the blade is oriented when cutting material as the spindle rotates. More helix angle makes transitions to the required axial depth of cut easier. Helix angles must be taken into account while working with different materials. This article explores the idea of a helix in machining, outlining the benefits and drawbacks and offering the best helix angle options for particular uses.

In the realm of machining, a comprehensive grasp of the intricacies associated with the helix angle proves indispensable, particularly when tailored to meet specific application requirements. By refining this angle, one can optimize machining processes to enhance effectiveness, achieve superior surface finishes, and prolong the lifespan of tools.

0086-813-8127573

0086-813-8127573