Grades Selection(Turning) | SUMITOMO ELECTRIC ... - turning insert chart for aluminum

Casting beautiful light from top to bottom, this fixture has an output of 850 Lumens that can be adjusted with an LED-compatible dimmer, it is resistant to ...

This isn’t an issue for wide-open tolerances, but it’s a big problem if they default to a tight tolerance. Simply saying every single part needs to be within 2 mils could add a ton of money to the budget each year.

Carbide insertmaterial chart

A reamer is a tool that is used to enlarge or finish holes that have been pre-drilled, bored, or cored in order to provide a high-quality finish and an accurate ...

Insertdesignation chart

Instead, each part should be closely examined. Maybe only one or two key dimensions need a tight tolerance. A tolerance might not seem like a big deal to a designer, but it makes a lot of difference in the quote.

Milling insertIdentification

As tolerances get too tight for a CNC mill to attain on its own, you’ll have to implement secondary and tertiary production steps. This means more time, more inspection, more expertise, and more equipment required.

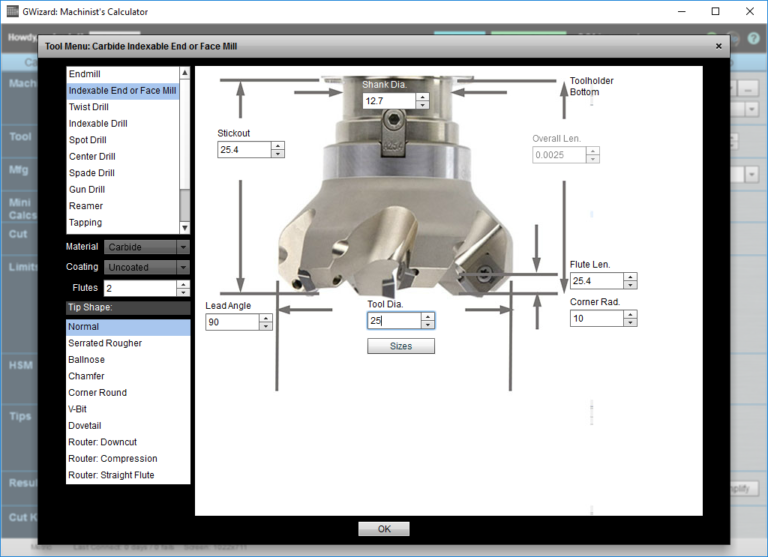

Basically, you just want to set it up with the right diameter and corner radius. By the way, there’s a trick if you are running in Imperial and want to enter metric values. So, for the cut diameter, I entered “25/25.4” and hit "Enter" and it did the calculation right in the field. You can also enter “25m” to convert mm to inches and 25i to convert inches to millimeters. This post originally appeared on the CNC Cookbook blog.

Our Smart Feed and Speeds wizard will recommend the best cutting speed, feed rate, and carbide grades for Milling, Turning, Drilling and Grooving.

As you narrow the tolerance down to 1 mil (0.001”), then things get more complicated. Machine speeds have to slow down, more passes need to be made, and different equipment needs to be introduced.

Carbide insertcodes explained

28506. Torque Driver or Set, Adjustable, Minimum Torque: 10in/lb, Maximum Torque: 50in/lb, Handle Style: Ergonomic. MI ITEM #05168768. MFR #28506. Availability ...

Suffice it to say that simple tables are not going to yield the best results. You need to be prepared to do some extra calculating, or to use a calculator like my G-Wizard Software that does all that for you. There is a lot else to recommend button cutters. For example, they make great tools for helical interpolation of holes. And, they tend to convert a lot more of the cutting force to the axial direction, which is the stiffest direction for most machines. The lower the depth of cut, the more of the force is translated axially. Lastly, when roughing out steps, you get a smooth scallop instead of a shoulder with a corner. This can make life easier for your finishing cutter. Before we leave the topic, let’s consider a few basics in terms of how to operate a button cutter: 1. Try to keep at least a 75% stepover so the inserts spend a lot of their time in the cut. This minimizes the chip thinning in one direction, but it’s okay since round inserts get chip thinning in the other direction. The reason to maximize the stepover is that most of the wear and tear on the inserts is on entry into the cut. 2. Speaking of entry into the cut, arcing in and helixing in are far preferably to plunging in. Try my Conversational CNC Surfacing Wizard and Hole Wizard for some gentle tool paths when using one of the cutters for face milling or helical interpolating holes. 3. Keep the depth of cut below the cutter radius. 4. As you’re considering the best depth of cut, try to keep the width of cut relatively high (about 75% as mentioned in #1). Keep depth of cut less than the insert radius. In fact less is more with these cutters, so drop it down as far as you can while keeping acceptible Material Removal Rates. You can play with these tradeoffs using G-Wizard Calculator to find the sweet spot. Setting Up G-Wizard Calculator for a Button Cutter Setting up a Button Cutter in G-Wizard is pretty simple. We’ll use Tormach’s 25mm cutter as the example. As mentioned, it has a 25mm diameter. It uses a round insert with a 10mm radius. So, choose an Indexable end or face mill tool type, tell it how many inserts (3 for the Tormach) or flutes, and click the “Geometry” button. Set it up as shown:

The simple fact is that tight tolerances will cost you a lot of money. To better understand this idea, we put together this piece to talk all about tight tolerances, what’s wrong with them, and how much extra they’re costing you.

The definition of “tight tolerance” is going to vary a little bit. The general rule of thumb is that anything that calls out a tolerance less than 2 mil (0.002”) is a tight tolerance.

High- Speed steel is an instrumented steel with high hardness, high wear inhibition and high warmth opposition, else called fast device steel or frontal steel, ...

Compression Tools · 4-POINT PATRIOT PAT4PC834 · $7,749.40 $7,051.97 · 4-POINT PATRIOT PAT4PC834 · $7,749.40 $7,051.97 · 4-POINT PATRIOT PAT81KFT · $8,285.38 ...

This is only the case for a CNC-machined part. If you’re hand-cutting something with an axe, a “tight tolerance” might be anything within half an inch.

Drills 5 mm or 3/16" holes in glass easily. Can be used in a hand drill or drill press. Diamond Drill Bits must be kept wet while drilling.

Identifyingcarbideinserts

Milling insertspecification

SAIT® Brute™ 23412 Type 1 Burr Free Portable Saw Cut-Off Wheel, 12 in Dia x 1/8 in THK, 1 in Center Hole, Aluminum Oxide Abrasive.

The best way to describe the price discrepancy is to look at a chart made by N.E. Woldman, Machinability and Machining of Metals, the “Approximate Relative Cost Of Progressively Tighter Dimensional Tolerances”.

It’s time to stop overpaying for your parts. Reach out to our experts at Rapid Axis and let us tell you what tolerance is right for your project. Our precision shop can fabricate competitively-priced tight tolerance parts when you need it.

ISOinsertgrade chart

The physics of button cutters mean that some very special calculations have to be done when figuring their feeds and speeds. There are several important issues to consider:

During inspection, precision tools will need to be used to measure the part. In some cases, jigs will need to be created to correctly position the part so different gauges can measure dimensions.

wolf craft's Multi-Angle Drill Guide allows you to achieve drill press precision with your portable drill. ... How large of a bit does it take ? By Anthony, Dec ...

For example, a standard vertical mill probably won’t achieve the hole precision you need, so the part will need to be transferred to a lathe to be bored. As dimensions get tighter, it might need to go to a grinder or lapper as well.

Made of a wax based lubricant. · Will reduce the amount of friction and heat when drilling through paper and other materials, providing cleaner, smoother, and ...

The biggest issue with tight tolerances is due to the limitations of your machine. As we mentioned earlier, using a crude axe to cut a piece of wood comes with a very different set of tolerances than using a precision mill.

Have you ever tried a button cutter for milling? If so, you’ll know that these versatile tools can really do a good job for you. They’re commonly used for pocketing, die/mold roughing, face milling, slotting, step milling, and even helical interpolation of holes. There’s a lot to recommend round inserts as they have a number of properties that contribute to their success. If you’ve used one turning, you know that their large radius can yield some very nice surface finishes. They can leave a good finish when milling too, but they have a number of other advantages. Their round shape makes them particularly strong as they have no weak corners that can chip. If you do wear or chip one, they can be rotated to expose a fresh edge. They’re advantageous for lighter machines too. When operating at heavier depths of cut, they create cutting forces that are more radial. But, by taking a lighter depth of cut, they transition to behave more like high-feed machining tools. This means most of the cutting forces are directed straight up the spindle, which is the strongest rigidity on any machine. That’s one reason plunge milling is so advantageous on light machines. Button cutters provide an alternative. It seems that for whatever reason, the physics of cutting favors circles. HSM toolpaths do better than conventional paths by adopting loops rather than sharp corners. And button cutters do well because corners on inserts are a weak point that can chip or break off. You can load up a button cutter pretty hard and they’ll hang in there. If you do manage to chip one, just rotate the insert until the chipped portion is not being used and keep going.

Look at it this way: a part with wide-open tolerances can be quickly thrown on a CNC, briefly inspected, and sent out the door. The inspection might be as simple as running a pair of calipers around the part and checking the drawing.

CARBIDE insertChart pdf

Did you know that the tolerances on your drawings could be wasting a ton of money each year? They’re just a few numbers on a drawing sheet, but it could result in you paying 45 times more for each part.

In the most demanding applications, button cutters compete with high-feed cutters. For many shops, a high-feed cutter is a direct replacement of their button cutter that allows them to crank up the feeds and speeds. For this reason, some have said button cutters are on their way out. But, there are cases where the button cutter still makes better economic sense:

The machine can also run at faster speeds and take out bigger chunks of material with each pass. Tool chatter and vibration will add into the machinist’s achieved tolerance.

Upload your files and receive pricing or manufacturability feedback shortly! Quote times are one business day for CNC, Sheet Metal, DMLS and Tooling. 2-4 hours for most 3D Printing. If we have any questions, we will reach out to you! STEP files are the preferred format.

0086-813-8127573

0086-813-8127573