Grinding Wheels Manufacturers & Suppliers - grinding wheel wholesalers

DiamondProducts catalog

Select Accept to consent or Reject to decline non-essential cookies for this use. You can update your choices at any time in your settings.

If you have the June issue of Moldmaking technology on your desk, flip open to page thirty to learn about our lightning quick, threaded medical part tool that we designed and built to put new technologies to the test. https://lnkd.in/eF-2BCw) You can see this mold run LIVE at Amerimold next week in Rosemont, IL. Diamond has teamed up with Progressive Components and Toshiba Machine Tool, and the mold will be running in Progressive's booth, booth #906. For complimentary show registration at Amerimold 2017, click: https://lnkd.in/eirpMmh Or enter offer code: EXHMT02 See you next week!

DiamondProducts Distributor

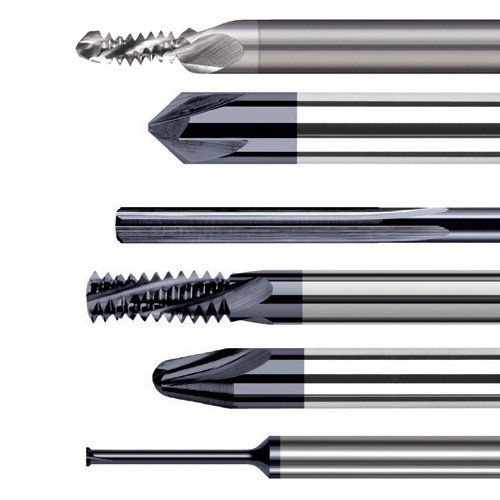

Since 1985, Harvey Tool has been known as a manufacturer of hard-to-find and innovative tools to solve challenging machining problems. They have a commitment to provide excellent service and quality tooling, with a strong desire to build long-term relationships with their machining partners. They specialize in miniature end mills, material specific end mills, specialty cutters, odd thread mills and various metalworking tools for challenging requirements.

Diamond is gearing up for the NPE Plastics Show in Orlando! Swing by our booth at W5393 (West Building Level 2) and let's chat about how we can ensure your next tooling project is a resounding success. We look forward to seeing you there!

Good morning from Day One of NPE 2024! Kent Smith and Bryan Amiot are in the booth and ready to talk molds. Stop by and see us at booth W5393.

Diamond ToolCompany

DiamondProducts list

Note: Some files are very large and could take time to preview. Guests may find it easier to download the file and view them locally.

Diamond specializes in crafting intricate, close-tolerance plastic injection molds and tooling. While medical and electronic applications constitute the largest portion of our business, we also excel in delivering projects for diverse industries that demand the same level of engineering precision and quality. With extensive experience across various injection mold requirements, our expertise encompasses injection molds, LSR molds, MIM molds, insert molds, multi-shot molds, unscrewing molds, hot runners, complex actions, and more. We take immense pride in our Design for Manufacturability (DFM) process, ensuring clear and thorough communication throughout the design, build, and maturation phases of your tooling. Our commitment to quality extends beyond processes to our investment in skilled staff and cutting-edge equipment, creating a robust resource for you to leverage in ensuring the success of your next project.

LinkedIn and 3rd parties use essential and non-essential cookies to provide, secure, analyze and improve our Services, and to show you relevant ads (including professional and job ads) on and off LinkedIn. Learn more in our Cookie Policy.

0086-813-8127573

0086-813-8127573