Grooving Inserts • PC Full Radius Precision Ground • Metric - radius grooving insert

Methods of producing work to the required tolerances to achieve a desired fit range from casting, forging and drilling for the widest tolerances through broaching, reaming, milling and turning to lapping and honing at the tightest tolerances.[1]

The study of Geometry is inherently a visual exercise. Since I started marking up diagrams with colors, I can say, without a doubt, kids just “get it” better and faster! Keep naming Geometry figures properly. Just enhance your names with colors and watch the difference it makes with your students! Never stop learning tips for Geometry teachers – your students will be more successful!

Fits of this kind are intended for the accurate location but with greater maximum clearance than class RC1. Parts made to this fit turn and move easily. This type is not designed for free run. Sliding fits in larger sizes may seize with small temperature changes due to little allowance for thermal expansion or contraction.

May 2, 2019 — These carbide drills are for use only with a drill press. They are very sharp, very hard and will cleanly drill through any material.

So, how can all these wonderful, colorful supplies be put to use in a Geometry class? Could this become one of your favorite tips for Geometry, too? Read on to see some great examples of how your students can use their beloved colored pencils, highlighters, or markers to drastically ramp up their participation and understanding of Geometry topics!

Your teacher was adamant about the school supply list on the first day of school. But the supplies were soon left behind as the day-to-day routine and grind kicked in.

I don’t remember exactly when I started this practice, but I can imagine it happened something like this: I asked my students to look at “triangle ABC” which I had drawn with a black Vis-à-vis marker on the overhead projector. (I know I’ve lost most of my audience, but there are a few of you out there who know what I am talking about. Anybody remember the days of scrolling and erasing, scrolling and erasing? Or flipping transparencies over and over to get them to face the right way? Remember the arm of your dominant hand covered in ink? I once bumped into a student in the grocery store who said, “Oh! Hi, Mrs. Patterson! It’s you! I didn’t recognize you without your overhead projector. I thought it was permanently attached to your hip!”).

Nov 26, 2020 — Downcut End Mill Chatter (Feeds and Speeds) · Set the router to the highest RPM you can bear (say, 18.000RPM) · In maple, aim for a chipload of ...

For example, if the lower limit of a hole is 25.05 mm and the upper limit of the same hole is 25.15 mm, then a hole that is 25.1 mm in diameter is within limits ...

The days of white chalk on a green or black chalkboard, and overhead projectors with black and blue overhead pens are long gone. (I confess. I miss them.) They have been replaced with Smartboards, large screen TVs, and a plethora of digital learning platforms. And you know what they all have in common? Colors! Markers! Highlighters! “Magic” pens! All at your fingertips, a tap or click away!

Engineering fits are generally used as part of geometric dimensioning and tolerancing when a part or assembly is designed. In engineering terms, the "fit" is the clearance between two mating parts, and the size of this clearance determines whether the parts can, at one end of the spectrum, move or rotate independently from each other or, at the other end, are temporarily or permanently joined. Engineering fits are generally described as a "shaft and hole" pairing, but are not necessarily limited to just round components. ISO is the internationally accepted standard for defining engineering fits, but ANSI is often still used in North America.

I am a retired high school math teacher. After taking a walk, enjoying my cup of tea and quiet time, I spend my days sharing tips and insights (from 27+ years in the classroom), or creating resources for teachers like you who love to save time, teach well, and be the teacher your students need! I live in the Dallas area with my husband.

Shrink fits serve the same purpose as force fits, but are achieved by heating one member to expand it while the other remains cool. The parts can then be easily put together with little applied force, but after cooling and contraction, the same dimensional interference exists as for a force fit. Like force fits, shrink fits range from FN 1 to FN 5.[3]

The International Organization for Standardization system splits the three main categories into several individual fits based on the allowable limits for hole and shaft size. Each fit is allocated a code, made up of a number and a letter, which is used on engineering drawings in place of upper & lower size limits to reduce clutter in detailed areas.

The best Diamond Tool prices in the country. Blades, Floor Grinder Tooling, Grinding Cups, Core Bits, Vacuum Bags/Filters.

Apr 2, 2019 — 'I hope everything is fine at your end. Does it mean "I hope you are doing well." Thanks.

H8tolerance

Are you looking for Geometry resources that will save you time and help you teach well? Then visit my Teachers Pay Teachers store. I am always adding new Geometry resources. You’ll find some Algebra 1 and Algebra 2 resources there, too!

If you are a new teacher – hang in there! If you sincerely pursue excellence in the craft of teaching, you will get better every year!

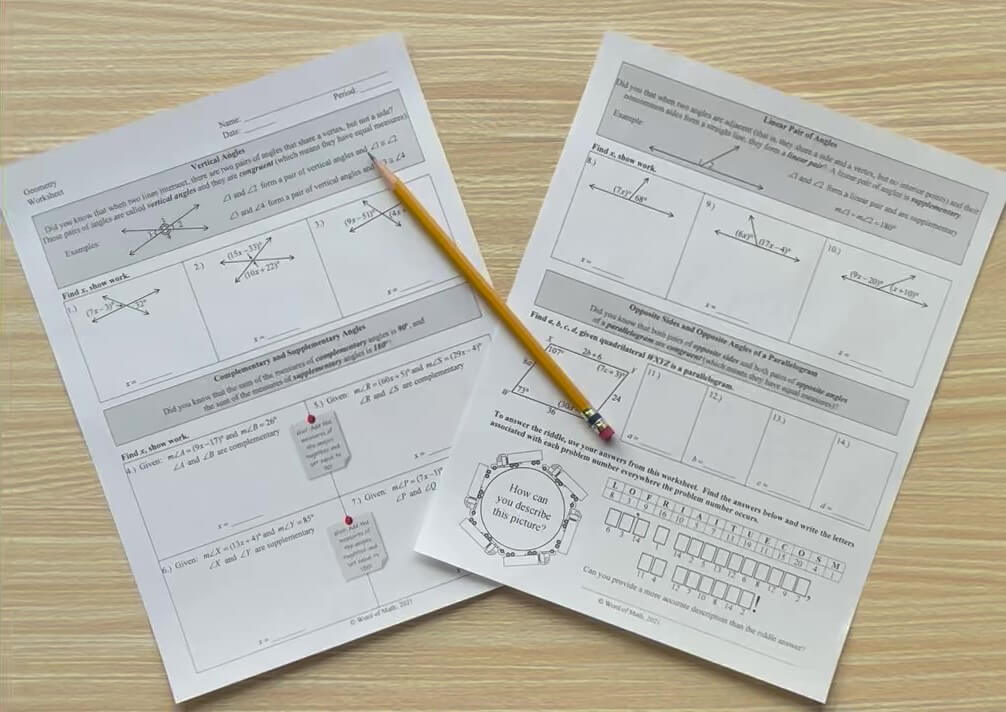

Here’s a great tip to help students identify the parts of a conditional statement. A conditional statement has a hypothesis and a conclusion. Ask your students to highlight (or underline) the hypothesis with one color, and the conclusion with another color.

Anyway, back to “triangle ABC”. When I asked my students to look at it, all I saw was a sea of blank faces. In a moment of impromptu inspiration, I picked up the blue Vis-à-vis marker and shaded in triangle ABC and said, “Look at the blue triangle ABC.” Aha! Heads tilted, glazed-over eyes focused, and the sound of a subtle, collective “Oh” wafted by.

I’m sure you’re not one of those teachers! If you ask families to battle the back-to-school sales and spend their hard-earned money on school supplies, you follow through and make sure they get used! Right? (Nod your head up and down, please.)

Bearing housingtolerance

Fits of this kind are about the closest fits which can be expected to run freely. Precision fits are intended for precision work at low speed, low bearing pressures, and light journal pressures. RC3 is not suitable where noticeable temperature differences occur.

Not saying I am old or anything, but my family did not own a color TV until I was a junior in high school. I still remember seeing “The Wizard of Oz” in color for the first time. When Dorothy walked out of her tornado ravaged home, into the land of Oz, I was stunned! I had no idea that Oz was in color! I thought it was like every other gray scale show I had grown up watching on a black and white TV. What a difference!

Standard Industrial Manufacturing Partners LLC. is a specialty manufacturer of fluid end expendables for plunger pumps and centrifugal pumps.

Before I continue, I want to remind you of the very real possibility that you could have a student in your class with color blindness. Please be aware and sensitive. There are easy practices you can seamlessly use to help students with color blindness as you try out this tip for Geometry. Read this helpful article from kidshealth.org for suggestions.

Fittolerance

Fits of this kind are mostly for running fits on accurate machinery with moderate surface speed, bearing pressures, and journal pressures where accurate location and minimum play are desired. Fits of this kind also can be described as smaller clearances with higher requirements for precision fit.

Engineeringtolerance

Changsha Cutoutil Hardware Tools Co.,LtD is a professional company specialized in cutting tools ,Diamond tools,Machine Accessories and measuring tools . And ...

How do you calculate speed and feed? · Speed (RPM) = (Surface Feet per Minute x 3.82) / Diameter of the Tool · Feed Rate = RPM x Chip Load x Number of Teeth · RPM ...

Perhaps one of my favorite uses of color is when I teach students about angles formed when a transversal intersects two (or more) other lines. Look at angle 1 and angle 2 in the diagram. When I want to teach students the name of the angle pair, I say, “Do you see how angle 1 and angle 2 are on alternating sides of the blue line and in the interior of the two black lines? These angles are called alternate interior angles.”

An amazing opportunity for better communication and student engagement awaits because you have an abundant palette of colors at the ready.

ISO 286

“Look at angles 5 and 6 on the same side of the green line and the interior of the black lines. They are called same side interior angles.” And on the lesson goes. I don’t remember exactly when I started using lines with color to teach angles formed by transversals, but since I did, the learning curve for students flattened and the time it took for mastery decreased dramatically! This practice has become one of my pro tips for Geometry teachers!

A fit is either specified as shaft-basis or hole-basis, depending on which part has its size controlled to determine the fit. In a hole-basis system, the size of the hole remains constant and the diameter of the shaft is varied to determine the fit; conversely, in a shaft-basis system the size of shaft remains constant and the hole diameter is varied to determine the fit.

Do this: Grab your virtual highlighter, mark up your diagram, and say, “The Segment Addition Postulate says the measure of blue segment PQ plus the measure of yellow segment QR is equal to the measure of green segment PR”.

The ISO system uses an alpha-numeric code to illustrate the tolerance ranges for the fit, with the upper-case representing the hole tolerance and lower-case representing the shaft. For example, in H7/h6 (a commonly-used fit) H7 represents the tolerance range of the hole and h6 represents the tolerance range of the shaft. These codes can be used by machinists or engineers to quickly identify the upper and lower size limits for either the hole or shaft. The potential range of clearance or interference can be found by subtracting the smallest shaft diameter from the largest hole, and largest shaft from the smallest hole.

Then I say, “Angle 3 and angle 4 are on alternating sides of the red line and the exterior of the black lines. What do you suppose they are called?” After a short pause, “Alternate exterior angles?”, says the class.

When you were a kid, did you ever have a teacher who asked for colored pencils, markers, highlighters, etc. on their list of required school supplies? You bought your supplies (either out of duty or – for those of us nerdy school supply loving people – with sheer exhilaration). But sadly, the school supplies disappeared into a black hole of your backpack, only to be rediscovered in their battered and unopened boxes at the end of the year. Forgotten. Never used. Sad.

If you’ve read this far, thank you! Thank you for being there for your students! (They need you more now than ever!) Thank you for investing a little time to think about tips for Geometry and finding the easiest way for your kids to learn Geometry. You are the best! Pat yourself on the back! You are doing amazing work in a challenging career!

Just like that, my students immediately knew which triangle I was talking about. And so began my love of one of my favorite tips for Geometry – using colors!

This is a pretty straightforward proof. Should be easy enough to follow along. Yet some students will still struggle. Why not use some color to help them along?

Take a look at the following two column proof. It has no color and therefore has the potential to lose your students’ attention and comprehension:

In the midst of the proof, you can say, “Segment AB, the longer side of the yellow triangle is congruent to segment BC, the longer side of the blue triangle.” And say, “Segment BM, the side shared by the yellow triangle and the blue triangle, is congruent to itself, etc…”

The smaller RC numbers have smaller clearances for tighter fits, the larger numbers have larger clearances for looser fits.[4]

Search tax records in Hidalgo and find Appraisal District information. Find Hidalgo property records, property tax rates, statistics and much more.

Toleranceh14

Could you use some great anytime, no prep Geometry freebies? Fill out the form below and I’ll send them to you right away!

Fits of this kind are intended for use where wide commercial tolerances may be required on the shaft. With these fits, the parts with great clearances with having great tolerances. Loose running fits may be exposed to effects of corrosion, contamination by dust, and thermal or mechanical deformations.

How about this? Instead of showing the following diagram and saying, “The Segment Addition Postulate says the measure of segment PQ plus the measure segment QR is equal to the measure of segment PR”…

As you prove each pair of segments congruent, mark the diagram with red tick marks. Then, write a red “S” next to each corresponding statement in the body of the proof (anyone else thinking of Superman here?). In addition to each red tick mark on the diagram and each red S in the body of the proof, you can also highlight the 3 statements where you and your class proved sides congruent and highlight the SSS justification in the same color. This makes it very obvious, to those who had a little trouble following along, that the two triangles are congruent because of the SSS Postulate.

NPT and NPTF pipe threads - dimensions according ANSI/ASME B1.20.1/3. NPT - National Pipe Thread Tapered - is a U.S. standard for tapered threads used to ...

Interference fit

Interference fits, also known as press fits or friction fits, are fastenings between two parts in which the inner component is larger than the outer component. Achieving an interference fit requires applying force during assembly. After the parts are joined, the mating surfaces will feel pressure due to friction, and deformation of the completed assembly will be observed.

Fits of this kind are intended for use where accuracy is not essential. It is suitable for great temperature variations. This fit is suitable to use without any special requirements for precise guiding of shafts into certain holes.

ISO and ANSI both group fits into three categories: clearance, location or transition, and interference. Within each category are several codes to define the size limits of the hole or shaft – the combination of which determines the type of fit. A fit is usually selected at the design stage according to whether the mating parts need to be accurately located, free to slide or rotate, separated easily, or resist separation. Cost is also a major factor in selecting a fit, as more accurate fits will be more expensive to produce, and tighter fits will be more expensive to assemble.

Fits of this kind are designed for machines running at higher running speeds, considerable bearing pressures, and heavy journal pressure. Fits of this kind also can be described with greater clearances with common requirements for fit precision.

I stumbled onto one my best tips for Geometry teachers in class one day. I wish I were one of those naturally gifted teachers whose best practices are as effortless as breathing. But, alas, I wasn’t one of those. My toolbox of useful teaching skills did indeed fill up, but it was thanks to the school of hard knocks. Year after year, I improved. Becoming an effective teacher, I discovered, happens when you commit to trial and error, grit, and loving it when your students are successful.

Tell the class, “Let’s prove orange triangle ABM congruent to blue triangle CBM using the SSS Postulate for congruent triangles. Every time we prove a pair of parts congruent, we’ll mark the diagram in red until we have enough congruent parts to guarantee congruent triangles.”

Force fits are designed to maintain a controlled pressure between mating parts, and are used where forces or torques are being transmitted through the joining point. Like interference fits, force fits are achieved by applying a force during component assembly.[3]

Rather than thinking, “Wait a second, slow down! Where is D? Where is E? Which triangle congruent to what????”, your students will think “Ah, yes teacher, I see.” You might even see some heads nod. You might get that “my-students-are-ready-to-move-on” feeling! (If you don’t recognize the feeling I’m talking about, you definitely know the “uh-oh-I-think-I’m-losing-them” feeling! Time for a do over!) It will be so much easier for your students to keep up when you refer to geometric figures with color!

0086-813-8127573

0086-813-8127573