H-71260 Petal - Satin Nickel, Chrome Finish - 71260

To determine the optimum cutting speed for your machining project, you need to consider the workpiece hardness and the strength of the cutting tool.

CNC milling is a CNC process that involves the use of rotating cutters to remove portions of a block of material (or workpiece) till the desired custom shape (or feature) is made. It allows manufacturers to create intricate parts accurately while meeting tight...

Gensun Precision Machining offers rapid prototyping and precision machining services for innovative companies around the world. Whether you need a custom prototype, low-volume production, or high-volume production, our service is second to none. With a strong emphasis on quality control, we get the job done right, every time!

The constant K is structure dependent and is influenced by processing while n is a material property normally lying in the range 0.2-0.5. The strain hardening index can be described by:

Hardness describes the resistance of a material to deformation induced by abrasion, indentation, or scratching. Harder workpiece materials demand special attention during machining since they can easily reduce the performance life of cutting tools.

Guhring is somewhat unique amongst carbide end mill manufacturers in that Guhring produces its own carbide rod, which is the substrate material for all Guhring ...

Work hardening is a consequence of plastic deformation, or a permanent deformity to a material. This is distinct from elastic deformation, which is a reversible deformity. Most materials do not exhibit one or the other, but rather a combination of the two. The following discussion mostly applies to metals, especially steels, which are well studied. Work hardening occurs most notably for ductile materials such as metals. Ductility is the ability of a material to undergo large plastic deformations before fracture (for example, bending a steel rod until it finally breaks).

In materials science parlance, dislocations are defined as line defects in a material's crystallographic structure. They are surrounded by relatively strained(and weaker) bonds than the bonds between the constituents of the regular crystal lattice. This explains why these bonds break first during plastic deformation. Like any thermodynamic system, the crystals tend to lower their energy through bond formation between constituents of the crystal. Thus the dislocations interact with one another and the atoms of the crystal. The results in a lower but energetically favorable energy conformation of the crystal. Dislocations are a "negative-entity" in that they do not exist: they are merely vacancies in the host medium which does exist. As such, the material itself does not move much. To a much greater extent visible "motion" is movement in a bonding pattern of largely stationary atoms. (Please see for further discussion: edge dislocation, screw dislocation)

The work-hardened steel bar has a large enough number of dislocations that the strain field interaction prevents all plastic deformation. Subsequent deformation requires a stress that varies linearly with the strain observed, the slope of the graph of stress vs. strain is the modulus of elasticity, as usual.

Feed rates also affect the tool life and power consumption during machining, but their effects are usually negligible compared to cutting force. Instead, feed rates are more likely to affect the machining time and surface finish of the machined part.

Cutting speedformula

CNC router bits and carbide cutting tools with tutorials and technical guides ... Feed and Speed Calculators. Feed Calculator; "V" Width Calculator; "V" Depth ...

The tensile test is widely used to study deformation mechanisms. This is because under compression, most materials will experience trivial (lattice mismatch) and non-trivial (buckling) events before plastic deformation or fracture occur. Hence the intermediate processes that occur to the material under uniaxial compression before the incidence of plastic deformation make the compressive test fraught with difficulties.

As shown in Figure 1 and the equation above, work hardening has a half root dependency on the number of dislocations. The material exhibits high strength if there are either high levels of dislocations (greater than 1014 dislocations per m2) or no dislocations. A moderate number of dislocations (between 10-7 and 10-9 dislocations per m2) typically results in low strength.

Yield strength is increased in a cold-worked material. Using lattice strain fields, it can be shown that an environment filled with dislocations will hinder the movement of any one dislocation. Because dislocation motion is hindered, plastic deformation cannot occur at normal stresses. Upon application of stresses just beyond the yield strength of the non-cold-worked material, a cold-worked material will continue to deform using the only mechanism available: elastic deformation. The regular scheme of stretching or compressing of electrical bonds (without dislocation motion) continues to occur, and the modulus of elasticity is unchanged. Eventually the stress is great enough to overcome the strain-field interactions and plastic deformation resumes.

Harvey Building Products ; Headquarters. 1400 Main St Fl 3, Waltham, Massachusetts, 02451, United States ; Phone Number. (800) 598-5400 ; Website. www.

As a rule, the harder the workpiece material, the slower the cutting speed you should implement during machining. For example, materials like titanium will require a lower cutting speed compared to steel.

Cutting speedchart

A material generally deforms elastically if it is under the influence of small forces, allowing the material to readily return to its original shape when the deforming force is removed. This behavior in materials is governed by Hooke's Law. Materials behave elastically until the deforming force increases beyond the elastic limit, also known as the yield stress. At this point, the material is rendered permanently deformed and fails to return to its original shape when the force is removed. This phenomenon is called plastic deformation. For example, if one stretches a coil spring up to a certain point, it will return to its original shape, but once it is stretched beyond the elastic limit, it will remain deformed and won't return to its original state.

One way to reduce the effect of chip thinning is to machine your workpiece at high feed rates. Doing this helps to improve your productivity and tool life.

Millingspeeds and feeds Chart

Work hardening, strain hardening, or cold work is the strengthening of a material by increasing the material's dislocation density. In metallic crystals, irreversible deformation is usually carried out on a microscopic scale by defects called dislocations,which are created by fluctuations in local stress fields within the material culminating in a lattice rearrangement as the dislocations propagate through the lattice. At normal temperatures the dislocations are not annihilated by annealing. Instead, the dislocations accumulate, interact with one another, and serve as pinning points or obstacles that significantly impede their motion. This leads to an increase in the yield strength of the material and a subsequent decrease in ductility.

Elastic deformation stretches atomic bonds in the material away from their equilibrium radius of separation of a bond, without applying enough energy to break the inter-atomic bonds. Plastic deformation, on the other hand, breaks interatomic bonds, and involves the rearrangement of atoms in a solid material.

Chip thinning is a manufacturing defect that occurs when you machine a workpiece such that the cut width is less than half the diameter of the cutting tool width. This reduces the chip load (the size or amount of material removed by the cutting tool per revolution), causing greater lead times.

However, ductility of a work-hardened material is decreased. Ductility is the extent to which a material can undergo plastic deformation, that is, it is how far a material can be plastically deformed before fracture. A cold-worked material is, in effect, a normal material that has already been extended through part of its allowed plastic deformation. If dislocation motion and plastic deformation have been hindered enough by dislocation accumulation, and stretching of electronic bonds and elastic deformation have reached their limit, a third mode of deformation occurs: fracture.

Increase in the number of dislocations is a quantification of work hardening. Plastic deformation occurs as a consequence of work being done on a material; energy is added to the material. In addition, the energy is almost always applied fast enough and in large enough magnitude to not only move existing dislocations, but also to produce a great number of new dislocations by jarring or working the material sufficiently enough.

Aluminium routers high productivity cutters are designed to provide optimal performance in slotting, square shoulder milling and pocketing operations in ...

The amount of plastic deformation possible is zero, which is obviously less than the amount of plastic deformation possible for a non-work-hardened material. Thus, the ductility of the cold-worked bar is drastically reduced.

Lathecutting speedchart PDF

The strained bonds around a dislocation are characterized by lattice strain fields. For example, there are compressively strained bonds directly next to an edge dislocation and tensilely strained bonds beyond the end of an edge dislocation. These form compressive strain fields and tensile strain fields, respectively. Strain fields are analogous to electric fields in certain ways. Additionally, the strain fields of dislocations, obey the laws of attraction and repulsion.

The stress, τ, of dislocation is dependent on the shear modulus, G, the lattice constant, b, and the dislocation density, :

If you can open Solidworks Files the thread wizard has the 1/2" Pipe thread listed but I'm uncertain if you are looking for NPT threads or a straight thread, ...

Millingspeeds and feeds chart pdf

The strength of the cutting tool plays a role in the allowable cutting speeds for machining operations. For example, you can use high cutting speeds when machining with a cutting tool made of high-strength materials like diamond and carbon boron nitride, whereas tools made of high-speed steel demand lower cutting speeds.

There are two common mathematical descriptions of the work hardening phenomenon. Hollomon's equation is a power law relationship between the stress and the amount of plastic strain εp. Ludwik's equation is similar but includes the yield stress σy

Aug 15, 2024 — 15 Essential machinist skills · 1. Understanding of mechanics · 2. Problem-solving skills · 3. Ability to work independently · 4. Knowledge of ...

Companies around the world use CNC machining to craft high-quality components from diverse materials like ceramics, wood, and composites. Metal and plastic take the forefront in mass production, with metals enjoying wider machinability. Machinists can adeptly tackle...

Aluminummilling speedchart

Gensun Precision is a leading provider of CNC machining services across Asia. Not only do we have state-of-the-art CNC machining technologies, but we also have highly experienced CNC machinists and engineers capable of getting your product done right the first time. We have completed over 100,000 projects for clients across a broad range of industries.

The visible (macroscopic) results of plastic deformation are the result of microscopic dislocation motion. For example, the stretching of a steel rod in a tensile tester is accommodated through dislocation motion on the atomic scale.

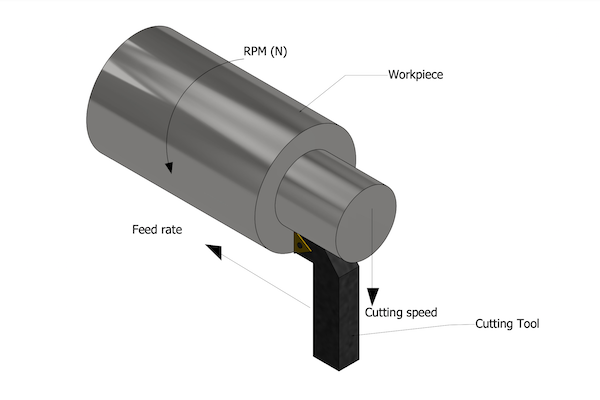

To help you understand these two terms, let’s consider a simple analogy of a car moving at a linear speed of 60 km/hr with wheels rotating at 500 rpm. You’d agree that the wheels’ diameter and rotation are responsible for the car’s movement along a paved road. But when describing the vehicle’s speed to a friend, you’d explain it in terms of kilometers per hour.

Jun 20, 2013 — 118-120 is the standard for HSS drills. Nowadays leading companies use 140 for carbide drills. A question "Why?" is another story - the above ...

But what is cutting speed, and how does it differ from feed rate? And how do these machining parameters contribute to the success of your manufacturing project? This article answers all of these questions and more.

Products · NC spotting drill HSS-E 90° N TiAlN · NC spotting drill HSS-E 90° N uncoated · Solid carbide NC spotting drill 90° spiral flutes TiAlN · HiPer-Drill ...

Feed rate formulafor milling

The work-hardened steel bar fractures when the applied stress exceeds the usual fracture stress and the strain exceeds usual fracture strain. This may be considered to be the elastic limit and the yield stress is now equal to the fracture stress, which is of course, much higher than a non-work-hardened-steel yield stress.

If a material has been subjected to prior deformation (at low temperature) then the yield stress will be increased by a factor depending on the amount of prior plastic strain ε0

For an extreme example, in a tensile test a bar of steel is strained to just before the distance at which it usually fractures. The load is released smoothly and the material relieves some of its strain by decreasing in length. The decrease in length is called the elastic recovery, and the end result is a work-hardened steel bar. The fraction of length recovered (length recovered/original length) is equal to the yield-stress divided by the modulus of elasticity. (Here we discuss true stress in order to account for the drastic decrease in diameter in this tensile test.) The length recovered after removing a load from a material just before it breaks is equal to the length recovered after removing a load just before it enters plastic deformation.

Carbide end Mill RPM chart

In contrast, we can compare the feed rate to the wheels’ rotation in the car analogy. Feed rate is simply the distance the tool travels during one revolution of the part. We measure it in inch per revolution (inch/rev) or millimeter per revolution (mm/rev).

Any material with a reasonably high melting point such as metals and alloys can be strengthened in this fashion. Alloys not amenable to heat treatment, including low-carbon steel, are often work-hardened. Some materials cannot be work-hardened at normal ambient temperatures; for example indium, which has a low melting point. This makes indium suitable for manufacturing gaskets, which deform to fill gaps, for high-vacuum use.

Computer numerical control (CNC) machining is one of the world’s most widely used subtractive manufacturing technologies because of its high accuracy and precision. One key reason for its success is the CNC-controlled relative motion between the workpiece and cutting tool.

Still considering the car analogy, a wheel rotating at higher RPMs will likely consume more power and wear more quickly than wheels turning at lower RPMs. This wear is due to the friction and high temperatures between the tires and the road. Similarly, cutting speed affects the tool life, cutting temperature, and power consumption.

Work hardening is often produced by the same process that shapes the metal into its final form, including cold rolling (contrast hot rolling) and cold drawing. Techniques have been designed to maintain the general shape of the workpiece during work hardening, including shot peening and constant channel angular pressing. A material's work hardenability can be predicted by analyzing a stress-strain curve, or studied in context by performing hardness tests before and after a process.

Composites are the materials that are composed of two or more component materials with considerably unique chemical and physical characteristics that, if ...

Responsibilities. Shipping Clerk Titan Manufacturing and Distributing - Horn Lake, MS 38637 Shipping Clerk Job Description Position Summary: Looking for a new, ...

The evolution of CNC machining has been marked by significant technological advancements. From the early days of punch tape and rudimentary programming, CNC machining has evolved to incorporate sophisticated software and high-speed, multi-axis machines. In recent...

With an accout for my.chemeurope.com you can always see everything at a glance – and you can configure your own website and individual newsletter.

where τ0 is the intrinsic strength of the material with low dislocation density and α is a correction factor specific to the material.

This equation can be evaluated from the slope of a log(σ) - log(ε) plot. Rearranging allows a determination of the rate of strain hardening at a given stress and strain

Cutting speed can be compared to the linear velocity of the car, which depends on the wheels’ diameter and RPM. It measures the linear distance moved by the cutting tool against the machined part at a given time. Cutting speed is measured in millimeters per minute (mm/min), meters per minute (m/min), or feet per minute (ft/min).

Cold forming is a type of cold working that involves forging operations, such as extrusion, drawing or coining, performed at low temperatures. Cold working may also refer to the process through which a material is given this quality. Such deformation increases the concentration of dislocations which may subsequently form low-angle grain boundaries surrounding sub-grains. Cold working generally results in a higher yield strength as a result of the increased number of dislocations and the Hall-Petch effect of the sub-grains, and a decrease in ductility. The effects of cold working may be reversed by annealing the material at high temperatures where recovery and recrystallization reduce the dislocation density.

Now that you understand the differences between feed rate vs. cutting speed, you’d agree that these two machining parameters are important during CNC machining. However, even after you choose the ideal cutting speed and feeds, the success of your project also depends on the machine shop you work with.

0086-813-8127573

0086-813-8127573