H5-OH2 Extended Reach - extendedreach

This article explains the many benefits of using stainless steel for your products and the challenges of working with it. We’ll also provide an overview of a few of the best stainless steel alloys for machined parts.

• Heavy-duty 135Â degree split point with gold finish for use in drilling hard tough metals, free machining stainless steel, high temperature alloy...

Despite its impressive balance of beneficial properties, CNC machining stainless steel does come with a few obstacles. Austenitic stainless steels in particular are prone to work hardening during machining which can make them even harder. This increases tool wear and can negatively impact the quality of the finished product if machinists are not familiar with machining stainless.

• Heavy-duty 135Â degree split point with gold finish for use in drilling hard tough metals, free machining stainless steel, high temperature alloy...

• Heavy-duty 135Â degree split point with gold finish for use in drilling hard tough metals, free machining stainless steel, high temperature alloy...

• Heavy-duty 135Â degree split point with gold finish for use in drilling hard tough metals, free machining stainless steel, high temperature alloy...

In a previous article, we highlighted 10 different steel alloys that are excellent choices for making machined parts. Of those alloys, 4 out of 10 were stainless steels:

Despite these challenges, experienced machinists with the right tools and equipment can reliably create high-quality parts when CNC machining stainless steel.

Additionally, stainless steel tends to have a lower thermal conductivity that allows heat to build up at the cut area. Without adequate cooling and the proper cutting parameters, these temperatures can be high enough to cause sensitization of the stainless steel. Depending on where the stainless steel part is being used, this could mean intergranular corrosion and stress corrosion cracking.

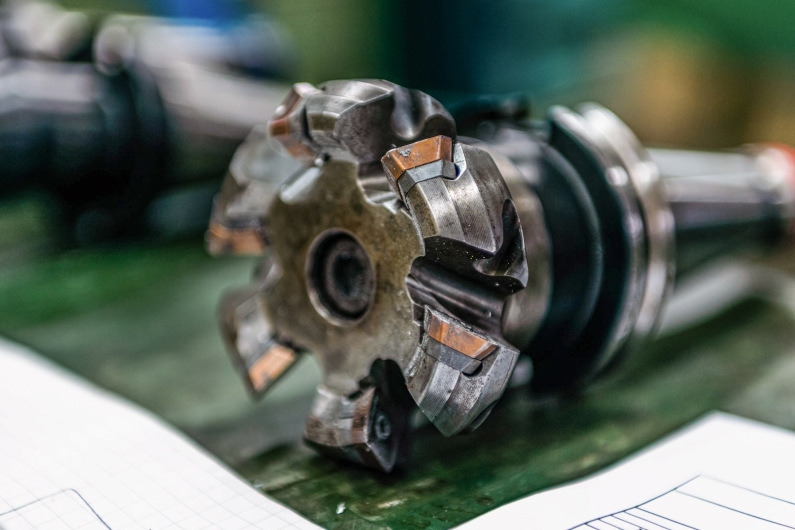

CNC milling is a CNC process that involves the use of rotating cutters to remove portions of a block of material (or workpiece) till the desired custom shape (or feature) is made. It allows manufacturers to create intricate parts accurately while meeting tight...

• The 130-MRO is a shorter (5") tougher version of our very popular 1/2" reduced shank product.• Designed specifically for the needs of the MRO mar...

Companies around the world use CNC machining to craft high-quality components from diverse materials like ceramics, wood, and composites. Metal and plastic take the forefront in mass production, with metals enjoying wider machinability. Machinists can adeptly tackle...

• Heavy-duty 135Â degree split point with gold finish for use in drilling hard tough metals, free machining stainless steel, high temperature alloy...

• Heavy-duty 135Â degree split point with gold finish for use in drilling hard tough metals, free machining stainless steel, high temperature alloy...

• Heavy-duty 135Â degree split point with gold finish for use in drilling hard tough metals, free machining stainless steel, high temperature alloy...

• Heavy-duty 135Â degree split point with gold finish for use in drilling hard tough metals, free machining stainless steel, high temperature alloy...

Gensun Precision Machining offers rapid prototyping and precision machining services for innovative companies around the world. Whether you need a custom prototype, low-volume production, or high-volume production, our service is second to none. With a strong emphasis on quality control, we get the job done right, every time!

The strength, hardness, machinability rating, and temperature resistance of stainless steel alloys lie somewhere between aluminum and titanium. Stainless steel however is also often cheaper than either aluminum or titanium alloys and has better weldability. But that doesn’t mean it doesn’t also present a few challenges.

• Heavy-duty 135Â degree split point with gold finish for use in drilling hard tough metals, free machining stainless steel, high temperature alloy...

• Heavy-duty 135Â degree split point with gold finish for use in drilling hard tough metals, free machining stainless steel, high temperature alloy...

• Heavy-duty 135Â degree split point with gold finish for use in drilling hard tough metals, free machining stainless steel, high temperature alloy...

• Heavy-duty 135Â degree split point with gold finish for use in drilling hard tough metals, free machining stainless steel, high temperature alloy...

Stainless steels are relatively hard, with a high mechanical strength that can be increased even further using heat treatments. To add to their impressive mechanical durability, stainless steel parts are very resistant to corrosion and chemical deterioration. They can even maintain their impressive properties at higher temperatures that cause many other materials to weaken or even melt.

Stainless steel is an excellent choice for creating strong and durable products. It offers a great combination of properties at a reasonable cost. And producers with concerns about machining efficiency can opt for an alloy like SS 416 that has better machinability.

CNC machining is a precise and effective manufacturing method for a wide range of materials, including metals and non-metals. The popularity of stainless steels as a machining material mostly comes from their unique balance of properties.

• Heavy-duty 135Â degree split point with gold finish for use in drilling hard tough metals, free machining stainless steel, high temperature alloy...

Stainless steel is just one of many classes of steel. It’s best known for its strength and durability, even in wet or corrosive environments. This makes it a very popular metal for both consumer products and industrial applications.

Overall, while stainless steels can be a bit more challenging to work with, the benefits are often worth it. That’s why designers should choose a reliable CNC machine shop like Gensun to create high-quality stainless steel products at an affordable cost.

Generally speaking, the primary alternatives for designers considering stainless steels are aluminum or titanium alloys. Depending on the alloys used and the conditions they experience, they can all offer impressive corrosion resistance.

• Heavy-duty 135Â degree split point with gold finish for use in drilling hard tough metals, free machining stainless steel, high temperature alloy...

• Heavy-duty 135Â degree split point with gold finish for use in drilling hard tough metals, free machining stainless steel, high temperature alloy...

• This general purpose 118Â degree point high-speed steel drill is recommended for use in drilling equipment with 1/2" chucks.• Type 130 drills may...

• Heavy-duty 135Â degree split point with gold finish for use in drilling hard tough metals, free machining stainless steel, high temperature alloy...

• Heavy-duty 135Â degree split point with gold finish for use in drilling hard tough metals, free machining stainless steel, high temperature alloy...

• Heavy-duty 135Â degree split point with gold finish for use in drilling hard tough metals, free machining stainless steel, high temperature alloy...

• Heavy-duty 135Â degree split point with gold finish for use in drilling hard tough metals, free machining stainless steel, high temperature alloy...

• Heavy-duty 135Â degree split point with gold finish for use in drilling hard tough metals, free machining stainless steel, high temperature alloy...

• Heavy-duty 135Â degree split point with gold finish for use in drilling hard tough metals, free machining stainless steel, high temperature alloy...

The evolution of CNC machining has been marked by significant technological advancements. From the early days of punch tape and rudimentary programming, CNC machining has evolved to incorporate sophisticated software and high-speed, multi-axis machines. In recent...

• Heavy-duty 135Â degree split point with gold finish for use in drilling hard tough metals, free machining stainless steel, high temperature alloy...

0086-813-8127573

0086-813-8127573