Harvey - 19562

A:Our company is based on ISO9001,we have more than 30 years experience of QC team and strictly quality control system.However,90 days of free change is provided.

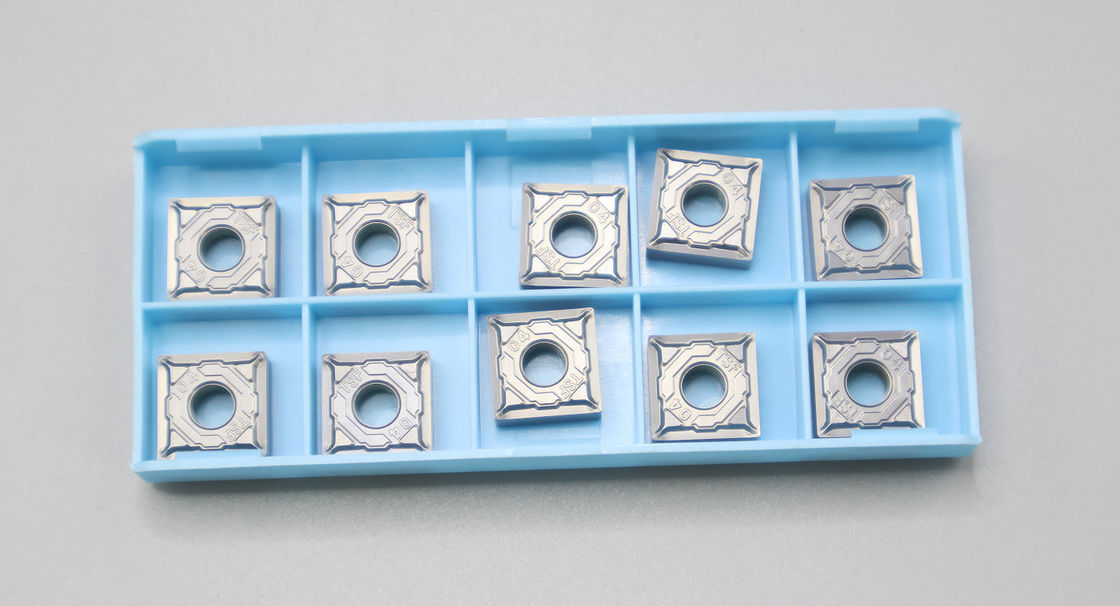

Q:What about the package?Carbide Inserts Solid Tungsten Carbide Turning Tool Inserts T Carbide Borning Insert Turning Blade SNMG1204

In general when operating a drill at a speed anywhere within its range for the particular material involved, increases in speed result in fewer holes before regrinding becomes necessary, and reduction in speed, more holes before the tool is dulled. The most economical speed for operating a drill will depend on may variables, some of which are: 1. Composition and hardness of material. 2. Depth of hole 3. Efficiency of cutting fluid 4. Type and condition of drilling machine 5. Difficulty of set-up Recommended speeds are shown in the flowing table. On most operations, it is usually better to start with a slower speed and build up to the maximum after trials indicate the job can be run faster.

0086-813-8127573

0086-813-8127573