Harvey - 64447

High-density sintered material made of ultra-fine grain diamond that demonstrates optimum wear and fracture resistance and excellent edge sharpness

Kennametalturningcatalogue pdf

Our 1st recommended grade for turning steel. Surface smoothing technology significantly suppresses adhesion of work material components. Achieves long, stable tool life with various cutting speeds and work materials

The tip angle of a masonry bit is often greater than that of a metal bit. A masonry bit has a different tip angle than an HSS bit, which is 135°, giving it extra strength. It uses both rotational and hammering forces to punch a hole as it drills.

Place your order online and receive order confirmation and shipping updates99% of our products are despatched same day from stock.

Carbidecoatingtypes

HSS bits are tough and resistant to heat. As a result, HSS is suitable for high-speed operation and provides a long-lasting performance.

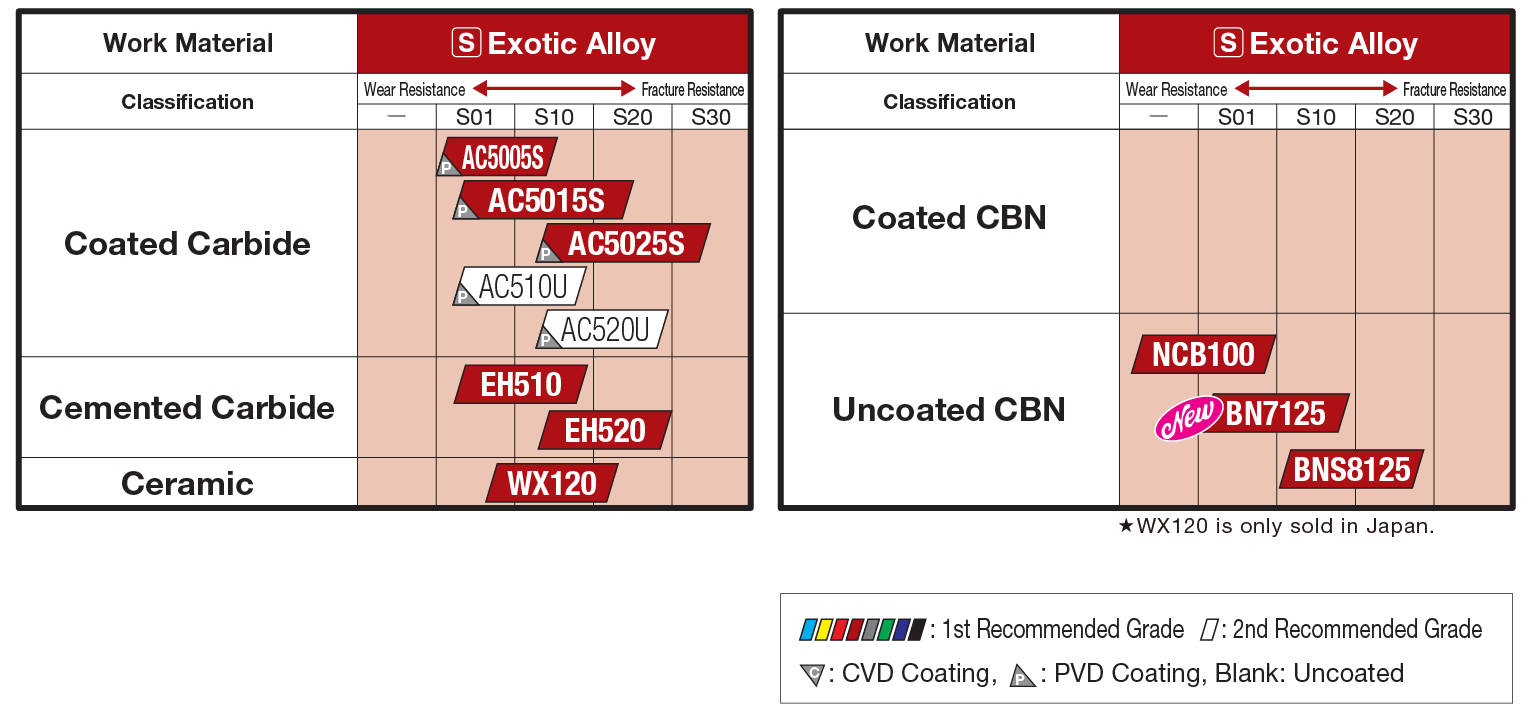

High-speed, high-efficiency grade with great high-temperature strength, which realises excellent wear resistance in high-efficiency machining

General-purpose grade with excellent wear resistance, fracture resistance, and thermal shock resistance, suitable for machining of cast iron and exotic alloys

Inserts forturningplastic

High-speed, high-efficiency grade with great high-temperature strength, which realises excellent wear resistance in high-efficiency machining

HSS drill bits are suitable for drilling iron, steel, and other metals such as brass, copper, and aluminum alloy. When drilling metals, HSS drill bits are more resistant to the heat created by the high-speed operation. Their resilience is so impressive that it can reach up to 650°C when operating. As a result, they can be employed at high drilling speeds on hard surfaces.

Masonry bits are usually used with a hammer drill. It is made of carbon steel and has a sloping tip frequently coated in carbide to give it more strength. Their large arrow-shaped heads help you identify masonry drill bits. The cutting tip of a conventional masonry bit is ground at an angle with no spur point in the center.

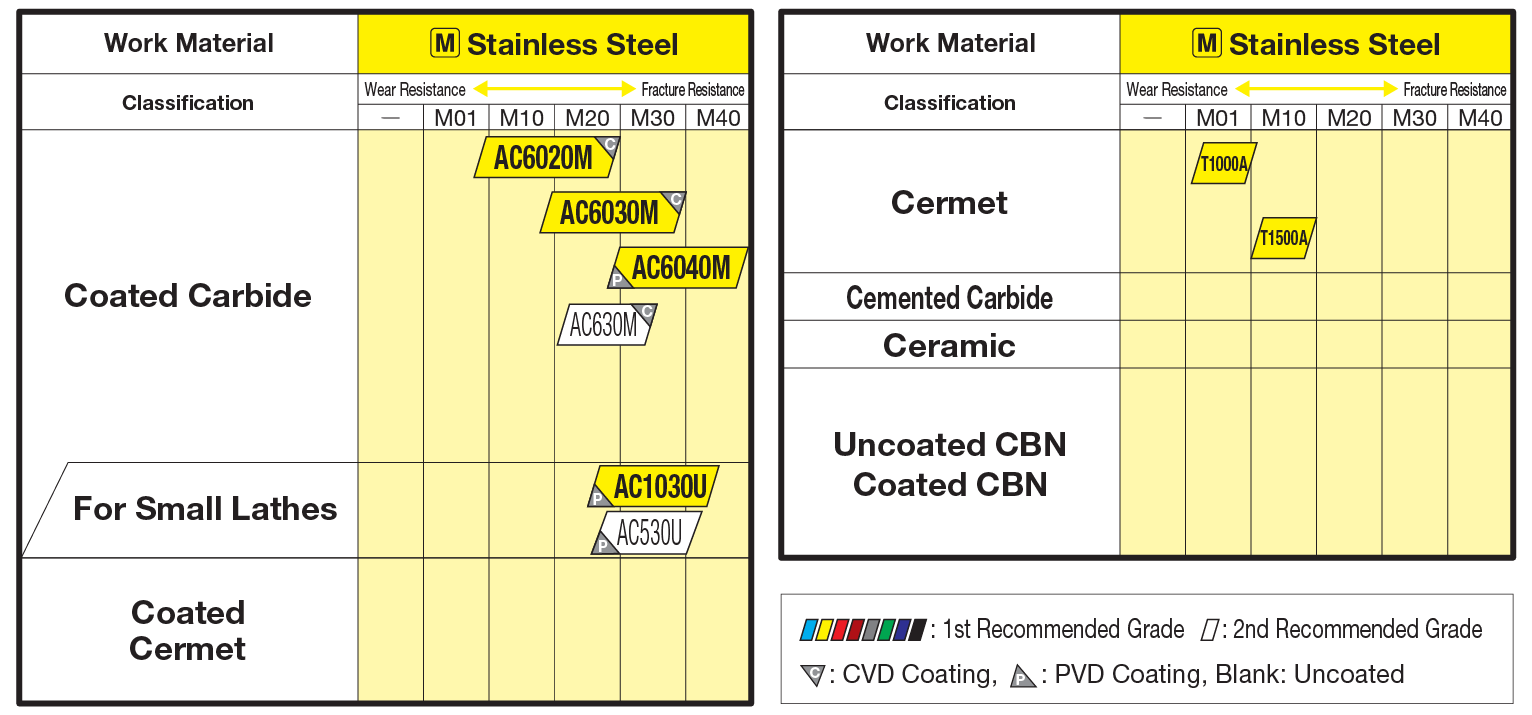

Tensile stress removal of the coating layer greatly improves fracture resistance. Achieves long, stable tool life during heavy interrupted cutting

Our 1st recommended grade for turning exotic alloys as it realises stable tool life with high-speed, high-efficiency machining

Superior fracture resistance, providing excellent stability in interrupted unstable cutting and when cutting mill-scaled work

High-hardness cermet with outstanding wear resistance and toughness. Realises high dimensional accuracy for continuous steel machining or finishing of powdered metal or cast iron

An SDS drill bit does not need to be tightened like an HSS drill bit. Instead, simply insert it into the SDS hammer drill's designated slots, and it will remain in place. Drilling the hole using an SDS drill bit ensures that you will go all the way through hard surfaces such as concrete faster and more efficiently.

SDS or "Spannen Durch System" drill bit was designed initially by Bosch features guiding slots. The shank is still circular, but at the very end, it becomes square and contains slots to be inserted into a hammer drill.

Combines a high-hardness carbide substrate with excellent wear resistance and a new CVD coating with improved coating strength to achieve both excellent wear resistance and fracture resistance. Achieves long, stable tool life during high-speed cutting

Development of crater damage is suppressed by controlling the orientation of the alumina crystal grains. Achieves long, stable tool life during high-speed and high feed cutting

100% diamond that directly binds nano-order diamond particles with high strength. Demonstrates optimum wear and fracture resistance as well as the best edge sharpness

Tough grade for titanium machining with excellent fracture and thermal resistance. Perfect for interrupted cutting and mill-scaled work

CarbideTurninginserts

A HSS drill has a circular shank inserted into the drill and is kept in place by three jaws that tighten around the shank. The problem with this configuration is that the jaws may not grip the shank tightly enough, mainly when the drill is in operation.

One significant distinction between a HSS drill bit and an SDS drill bit is how the drill bit is chucked or fastened inside the drill. HSS drill bits are compatible with any standard chuck.

Employs Brilliant Coat PVD coating with excellent lubricity to provide better wear resistance and consistent surface finishes in low-speed cutting applications such as machining of small products or low carbon steel

Alumina coating with even higher strength balances outstanding stability and wear resistance in mill-scale work on forged material. Gold-colored coating makes used corners easily identifiable

The primary distinction between masonry and an HSS drill bit is their function. HSS drill bits are typically used for metals, whereas masonry drill bits are used for concrete bricks and other comparable materials.

Insert coatingchart

All orders placed before 5:00pm Monday to Thursday and 3:00pm Friday will be dispatched on a next day carrier service. Carriage is free on all orders over £50 (Excluding VAT), if below £50 then next day delivery is £6.50

Superior wear and plastic deformation resistant grade, that utilizes a high hardness carbide substrate coupled with the high hardness Super FF Coat for high speed to continuous turning of Cast Iron

Achieves high-efficiency, improved machining accuracy, and long tool life in machining of exotic alloys such as titanium alloy and Co-Cr alloys

Our 1st recommended grade for turning of stainless steel, achieving long and stable machining. Drastically reduces the abnormal damage common in stainless steel machining, thanks to the improved coating strength and excellent adhesion

Carbidecoatingfor aluminum

It's pretty forgiving when it comes to hand drill and drill press operations. HSS is also very economical since it can be reused and resharpened to extend its life. In addition, HSS drill bits are sometimes coated with black oxide or titanium to prevent corrosion and reduce friction.

High-hardness cermet with outstanding wear resistance and toughness. Realises high dimensional accuracy for continuous steel machining or finishing of powdered metal or cast iron

The shanks of SDS and SDS-Plus drill bits are interchangeable and have a diameter of 10 mm. Unfortunately, the spline is not compatible with SDS-MAX drill bits. However, you can find after-market adapters so that you can use these drill bits interchangeably.

how many types of commercialcoatingprocess carried out on carbides?

High-hardness cermet with outstanding wear resistance and toughness. Realises high dimensional accuracy for continuous steel machining or finishing of powdered metal or cast iron

Drastically improves reliability in the unstable cutting range, thanks to the excellent adhesion and peel-off resistance of the new PVD coating as well as the improved fracture resistance of the dedicated carbide substrate

A general-purpose cermet made from hard grains with different grain sizes, delivering functionality that provides an excellent balance of wear resistance and toughness, along with good surface finish quality

Our 1st recommended grade for ductile cast iron. New high-adhesion, high-strength CVD coating realises both wear resistance and chipping resistance

Employs a new PVD coating, and a dedicated tough carbide substrate. High-quality cutting edge grade suppresses adhesion and micro-chipping, realizing excellent machined surface quality

A new cermet substrate with excellent thermal conductivity is used to achieve outstanding thermal crack resistance. Also uses Brilliant Coat, which has excellent lubricity

High-precision grade realizing long tool life with excellent surface roughness and stable machining. Maintains excellent surface roughness thanks to a high notch-wear resistant coating and tough CBN substrate

1st recommended grade, balancing excellent wear resistance and fracture resistance in hardened steel machining.Along with a tough CBN substrate, the coating combines wear resistance and toughness to achieve long, stable tool life even in high-efficiency and interrupted machining

The most economical general-purpose drill material is high-speed steel. It is a cost-effective solution for many drilling applications. It is a popular metal drill bit material that can drill safely through several types of metals, plastic, and hardwood.

General-purpose grade for titanium machining that features excellent wear and thermal resistance. For applications from roughing to finishing

PVDcoating

For high-speed machining, BN1000 provides the highest wear resistance of all uncoated SUMIBORON grades, improving fracture resistance while maintaining an emphasis on wear resistance

High-speed, high-efficiency grade with great high-temperature strength, which realises excellent wear resistance in high-efficiency machining

HSS bits are made of carbon steel with the addition of additional elements such as chrome and vanadium. As a result, they are incredibly durable and are well suited for drilling into metal surfaces.

A general-purpose cermet made from hard grains with different grain sizes, delivering functionality that provides an excellent balance of wear resistance and toughness, along with good surface finish quality

High-hardness cermet with outstanding wear resistance and toughness. Realises high dimensional accuracy for continuous steel machining or finishing of powdered metal or cast iron

0086-813-8127573

0086-813-8127573