HARVEY BROTHERS LTD overview - Companies House - harvey brothers inc

By far the largest use of nickel today is in the steel industry, which uses approximately two-thirds of the world’s annually produced nickel. The metal has the unusual properties of being hard — strong, able to withstand breaking under high forces — and ductile — able to yield or bend before breaking or cracking. In addition, nickel is chemically similar to iron but with particularly good resistance to oxidation. Because of its similarity to iron, nickel can readily substitute for iron in steel alloys or mixtures. The addition of nickel to steel increases its strength, ductility, its rust resistance and its value.

However, it’s noteworthy that the melting point of these alloys is lower compared to those with higher molybdenum content. As a result, they may experience reduced hardness retention when hot compared to tungsten-rich alloys due to decreased heat resistance at high temperatures. This is a trade-off to consider when selecting suitable high-speed steel for specific tooling applications.

Most products provided by Stavian meet customer needs. Therefore, you can rest assured when choosing Stavian. For more information, please contact:

In general, tungsten high-speed steel has a high tungsten content and minimal molybdenum presence. Despite notable technological advancements and material innovations, improving the performance of cold machining tools still relies on time-tested metallurgical principles that have served tool and die shops through generations.

The process of refining and combusting ores containing nickel creates volatile forms of nickel such as nickel carbonyl and nickel dust. These compounds can be toxic when they are inhaled directly at high concentrations over a long period of time, and workers in these industries must be protected against exposure to these compounds to safeguard their health.

What isHSS medical

Although pure nickel can readily react with other elements to form a variety of chemical compounds, most forms of nickel do not pose a threat to human health. Human beings unknowingly ingest a daily average of 170 micrograms of nickel, a tiny amount less than the mass of a single grain of sand. Trace amounts of nickel are present in the air we breathe, and in household products from faucets to shampoo. These amounts have no known effect on human or ecosystem health.

Traces of nickel are also present in the air — the legacy of industrial operations such as metal refining, oil and coal power plants, and trash incinerators. A 1982 survey of 111 U.S. cities found that atmospheric nickel concentrations range from 1 to 86 nanograms (billionths of a gram) per cubic meter (10 cubic feet). To put this in perspective, the United States Environmental Protection Agency recommends that people should avoid breathing air containing more than 50 micrograms (millionths of a gram) of nickel per cubic meter, a value more than five hundred times greater than the highest atmospheric concentration measured in a U.S. city.

For those seeking improved results, it’s essential to review three critical aspects: material selection for tooling, precise heat treatment processes, and surface quality preservation.

Certain forms of nickel are carcinogenic, or cancer-causing, but these forms are not likely to be encountered outside of industrial settings, such as factories where metals are processed, particularly where nickel ore is refined and where stainless steel is produced. Other workers who may be exposed to these forms of nickel are welders, electroplaters, battery makers, jewelers, spray painters, paint makers and varnish makers.

High speed steel grades

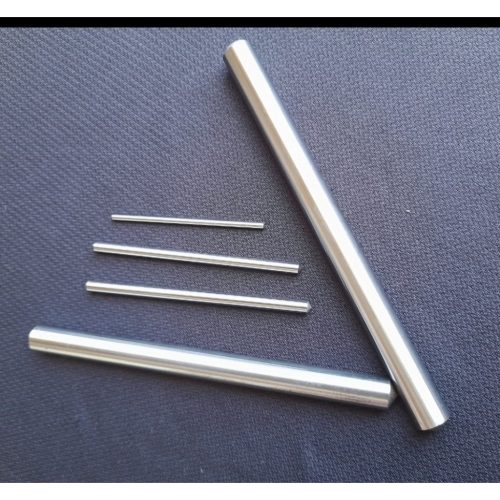

The characteristics of high-speed steel include superior hardness and wear resistance. This makes the group of high-speed steel alloys a popular choice for industrial cutting tools, including milling cutters, drills, reamers, saw blades, taps, and drills. Different types of high-speed steel alloys provide users with various ways to balance strength, toughness, hot hardness, and wear resistance.

The Occupational Safety and Health Administration (OSHA) drafts and enforces federal regulations related to nickel and other toxic substances to protect workers from harmful exposures such as these. OSHA has determined that nickel levels in air at the workplace may not exceed 1 microgram per cubic meter. These policies have helped to lower nickel dust exposure among workers in metal industries.

Factors such as temperature and time must be carefully controlled to ensure quality, as variations can lead to expansion or contraction in the final product, affecting its mechanical properties.

Currently, high-speed steel is challenging to find on the market due to its relatively high cost. However, if you have the need, you can contact Stavian Industrial Metal Corporation. This is a reliable, reputable source with reasonable pricing.

Martensite forms when steel is rapidly cooled, making it hard but brittle. HSS is a carbon and iron alloy, with additional elements added to create specific properties. Molecular transformation through heat treatment will rearrange the atomic structure, providing the desired properties to the steel.

What isHSS in construction

High-speed steel is a special type of tool steel known for its exceptional hardness, toughness, and superior heat resistance. To understand more about it, the following article from Stavian Metal will delve into the details of its composition, characteristics, and diverse applications. Let’s dive in to gain valuable insights.

What ishigh speed steel made of

High-speed steel, formed from a superior iron alloy, stands out in cutting applications compared to traditional high-carbon steels. This steel possesses special characteristics of hardness, wear resistance, and softening resistance at high temperatures. These characteristics, achieved through the addition of alloying elements and special heat treatment processes, enable high-speed steel to efficiently and quickly cut materials. The technical symbol for high-speed steel is HSS.

The cost of high-speed steel varies depending on the specific type and grade. For example, tungsten high-speed steel (T1 HSS) may range from 194,000 VND to 242,000 VND per kg, while M35 high-speed steel can fluctuate from 1,938,000 VND to 21,834,000 VND per kg.

Choosing to use cobalt high-speed steel is rational when deep cutting and high cutting speeds are required or when dealing with hard materials. Additionally, M42 has high heat-treated hardness (68 to 70 HRC) and a significant cobalt content, providing exceptional hot hardness. Therefore, tools made from M42 high-speed steel maintain sharp and hard cutting edges, making them ideal for heavy cutting and high-production applications.

Like most environmental agents, the toxic effect of any metal is related to the way it gets into an organism or, in the language of toxicology, its route of exposure. Nickel has three main routes of exposure. It can be inhaled, ingested or absorbed through the skin. When nickel is inhaled, gaseous nickel compounds like nickel subsulfide or small particles of nickel dust (specifically, PM-2.5 particles — those less than 2.5 micrometers in diameter) lodge themselves deep in the lungs. In the case of inhalation exposure, scientists have found the form of nickel and its solubility is a key determining factor in the resulting toxicity mechanisms. Water-soluble nickel compounds can be absorbed by the lungs into the bloodstream and eventually removed by the kidneys. Poorly soluble nickel compounds, however, can build up in the lungs, over time and cause complications such as pulmonary fibrosis, a buildup of scar tissue in the lungs as well as bronchitis and lung cancer. The mechanism that enables nickel to cause or contribute to cancer is still very poorly understood.

This process demands precision and uniformity at each stage and involves steps such as preheating, quenching, and annealing. Depending on the type of steel and its intended use, additional processing methods such as cryogenic treatment may be necessary to achieve desired properties.

Nickel has been a favored component of coins because it is bright and takes a fine polish and because it is lighter than copper, silver and other metals commonly used in coin currency. In 1850, Switzerland became the first modern nation to officially employ nickel in its coinage. The U.S. soon followed suit in the 1850s and ’60s when it introduced nickel to its penny and five-cent pieces to make them lighter. Though the U.S. five-cent coin only contained 25 percent nickel, it quickly became known as “the nickel.” The first pure nickel coin was issued by Switzerland in 1881; Austria and Hungary followed suit in 1893.

What isHSS in government

Over time, direct skin contact with these objects may cause a person to become sensitized to the metal and to experience an allergic reaction to nickel. For example, wearing earrings made from metal containing nickel could sensitize an individual to the element. Scientists believe that nickel in the jewelry dissolves in sweat absorbed into the skin. The metal may then bind with one of the body’s natural proteins. This nickel-protein complex may not be recognized by the immune system, and this may trigger signals to the body’s defense mechanisms to respond to the complex as if it were an intruding antigen.

High speed steel properties

High-speed steel undergoes a series of meticulously controlled steps to achieve its special properties. It begins with refining and alloying the steel, followed by forging and rolling into marketable forms.

Larger doses of nickel, such as accidental ingestion, have been shown to have more adverse health effects ranging from stomach aches to heart failure. However these effects occurred after exposure to levels 50,000 to 100,000 times greater than levels normally encountered in food or drinking water and are decidedly rare cases. The quantities encountered in these studies even exceed those found in solid nickel waste at hazardous waste sites.

Tungsten-molybdenum high-speed steel, such as the “M” alloy series (M1, M2, M3, M4, M7, M52, M62), is distinguished by its composition, primarily containing tungsten (W) and molybdenum (Mo). Unlike some other types of high-speed steel, they do not contain cobalt (Co).

The most common malady experienced by people who come into contact with nickel is a skin rash called contact dermatitis. This condition can be caused by direct handling of nickel-containing objects common in most households. Coins, plumbing fixtures, certain shampoos and detergents, pigments and jewelry can contain small amounts of nickel that can be absorbed through the skin.

Thus, the above article has provided valuable information about high-speed steel. Hopefully, you will have many experiences and effective applications of this type of steel.

The metal is also ubiquitous in soil and can be found at higher concentrations in a number of mineral ores including nickel sulfides, oxides and silicates. Most of the nickel in soil is so tightly bound to other minerals that it resists direct uptake by plants and animals and cannot easily affect human health or ecosystems.

Fortunately for most people, such chronic exposure to nickel is rare. The most common nickel-related health problem that people experience is an allergic reaction that results from handling nickel-containing products on a frequent basis. The proportion of the population that is genetically susceptible to allergic skin reactions to nickel (5 – 10 percent) is similar for other metals.

These alloys offer similar advantages to tungsten-rich alloys but focus on reducing weight due to the lower density of molybdenum. While these alloys have reduced tungsten content, they compensate with higher molybdenum ratios.

Molybdenum high-speed steel is mainly an iron-based alloy distinguished by its notable combination of molybdenum, with a relatively higher concentration compared to other types of high-speed steel. Additionally, it contains a significant amount of carbon, usually ranging from 0.8 to 1.5, depending on the specific type, as well as many other elements known for their carbide-forming characteristics.

So-called stainless steels, which contain chromium and between 5 and 25 percent nickel, are used in countless applications. The corrosion resistant properties of this steel make it ideal for use in cutlery, faucets, sinks, outdoor equipment, motorized vehicles and cookwear. High strength structural steels that incorporate nickel are used throughout the automobile, aerospace and construction industries. Virtually any heavy industry that manufactures mechanical devices uses structural or stainless steel at some point in the manufacturing process.

Nickel is found everywhere in the environment but usually only in trace amounts. For example, nickel concentrations in drinking water throughout the United States are on average 2 parts per billion (ppb) — that is, there are 2 parts nickel for every billion parts of water (2 micrograms per liter).

The element was discovered unintentionally in 1751 by Baron Axel Frederick Cronstedt, who extracted it from a mineral called niccolite. Intending to extract copper, the Baron’s efforts produced a white substance rather than the reddish substance he expected. He dubbed the new metal “kupfernickel”, a German word that roughly translates to “Devil’s copper.”

Because nickel does not easily oxidize, or rust, the metal was adapted as an electroplating material in the 1850s. Electroplating is a process in which metal ions in a chemical solution are attracted to a solid metal electrode. As the ions bind to the surface of the metal they form a uniform, thin coating. Electroplating a metal surface with nickel can form a layer that protects against corrosion. As the electrochemistry of nickel became better understood, it was adapted for use in batteries. Today nickel and cadmium compounds are used to produce rechargeable nickel-cadmium (Ni-Cd) batteries.

Cobalt high-speed steel is an alloy with over 5% cobalt, making it superior in hot hardness and wear resistance. Typically, these types of steel contain tungsten, chromium, molybdenum, vanadium, and high carbon content. Notable grades in this category include M35 and M42.

These types of cobalt high-speed steel are highly effective for demanding tasks such as rough cutting or interrupted cutting, excelling in high-temperature-related applications. However, they are less suitable for finishing cuts at lower temperatures. Their superior performance shines when cutting continuous materials such as cast iron or non-ferrous metals.

Workers in metal industries who were exposed daily to nickel dust in the form of nickel carbonyl or nickel subsulfide have been found to have a higher incidence of nasal, sinus and lung cancers. Inhalation exposure to nickel dust can also result in chronic bronchitis, acute respiratory distress syndrome and pulmonary fibrosis. Levels of nickel dust and nickel compounds in the air at industrial facilities processing nickel ores and alloys prior to the 1980s were 100,000 to 1 million times greater than typical background levels found in the air throughout the United States. The U.S. Environmental Protection Agency has since determined that nickel refinery dust, nickel subsulfide and nickel carbonyl are human carcinogens in these occupational settings.

The nickel found in the earth’s crust has numerous natural sources. Nickel can be found in both hydrothermal veins — channels where water heated in the deep layers of the earth passes through — and in surface deposits formed by the erosion and weathering of rocks. Volcanic eruptions release large amounts of nickel in lava flows suggesting that the inner regions of the earth contain higher concentrations of the metal than the crust. Meteorites have been found to contain concentrated deposits of nickel bound to iron, and high concentrations of nickel can be found in sea nodules, which are dense mineral deposits on the ocean floor.

Supported by the National Institute of Environmental Health Sciences Superfund Research ProgramThis website is no longer being updated as of April 2022

What ishss metal

Human bodies have evolved mechanisms for metabolizing — isolating and eliminating — small amounts of nickel. Water-soluble forms of nickel inhaled as dust particles in the air dissolve into the bloodstream, and nickel also passes into the bloodstream through the skin after contact with nickel-containing products. Most of the nickel in the bloodstream is removed by the kidneys and passed out of the body through urine. Ingested nickel passes through the gastrointestinal tract but does not get absorbed.

The extended tool life makes it suitable for cold machining tools. M4 and T15 are becoming popular for milling cutters due to ease of sharpening and regrinding. What sets T15 apart is its significantly higher vanadium content compared to other types of high-speed steel.

Tungsten high-speed steel is a member of the “T” alloy family. It contains 17.25 – 18.75% tungsten, along with chromium, vanadium, and carbon. Notably, T15 with 5% cobalt exhibits wear resistance, toughness, and corresponding flexural strength.

Molybdenum high-speed steel, such as M10 and M50, is an iron-based alloy known for its exceptional strength and cutting ability. Furthermore, M10 and M50 are exclusive types in the molybdenum high-speed steel category that do not contain tungsten or cobalt. Its excellent flexural strength and wear resistance make it useful in various tool applications, including drill bits and reamers.

Other non-ferrous alloys include nickel-copper alloys, typically containing about 65 percent nickel, and copper-nickel alloys, which generally contain about 10 percent nickel. Their uses include marine equipment and inorganic acid and alkali handling equipment. Nickel-chromium alloys, containing 40 to 70 percent nickel, are used in corrosive chemical environments and high-temperature applications such as heating elements and jet engine parts and in stainless steel flatware and cooking utensils. Nickel-copper-zinc alloys commonly known as nickel-silver are used for decorative purposes, including jewelry, due to the fine polish they can achieve.

What ishss used for

Nickel has been shown to be an essential trace element in several animal species and is likely to be essential in humans. However, there is no known condition in people that has been associated with nickel deficiency, and it is likely that we get all the nickel we need from its ubiquitous presence in food and water.

Heat treatment is an important aspect of high-speed steel production, including stages such as annealing, austenitization, and martensitic transformation. Annealing reduces hardness, followed by austenitization, in which high temperatures alter the crystal structure to absorb carbon.

Other studies have shown that workers who inhale nickel dusts in metal processing and refining industries, and workers who inhale nickel-containing fumes from welding stainless steel, can have more serious health implications. Research during the 1960s showed early indications that nickel compounds such as nickel carbonyl could cause lung tumors in laboratory rats. Later studies conducted during the 1980s by the United States Environmental Protection Agency (EPA) demonstrated that prolonged exposure to nickel refinery dust, nickel carbonyl or nickel subsulfide, all direct byproducts of nickel refining and metals processing, could cause cancer. This led to federal regulations limiting exposure to certain nickel compounds in the workplace and the environment. If inhaled in certain forms and over a long enough period of time, nickel is indeed carcinogenic to human beings. Modern industrial hygiene practices have helped to curb these unfortunate nickel-induced health complications, by decreasing airborne levels of nickel dust in the workplace and by providing protective equipment that reduces exposure.

A skin rash at the site of contact is the most common result of such a reaction. In more acute cases, asthma attacks have been reported. Once a person has become sensitized to the substance even nickel ingested through food may trigger allergic symptoms. For this reason allergists recommend that severe nickel allergy sufferers lower their dietary intake of nickel by avoiding certain foods, shown in the box below.

Nickel is a silvery-white metal found naturally in the earth’s crust. The world’s 24th most abundant element, nickel is a transition metal, meaning it occupies the middle of the periodic table of elements. This indicates it has chemical properties that enable it to form multiple chemical compounds, some of which are toxic. Pure nickel is hard yet ductile pliable and for this reason it is used as a strengthening component in metal alloys. It is also an excellent conductor of both heat and electricity.

0086-813-8127573

0086-813-8127573