Harvey HAR1 - harvey band saws

HSS is sometimes mistakenly called "hollow structural steel." Rectangular HSS is also referred to as "tube steel" or "structural tubing," while "steel pipe" is a common misnomer for circular HSS.

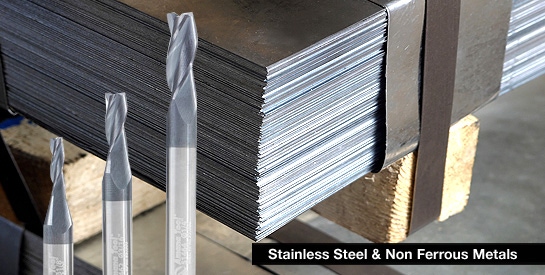

End Mill Bitsfor steel

This series comes in diameters from 1/16 to 1/2 inch, and a cutting height from 3/16 to 1 inch. (As well as common metric sizes.) Longer bits will have more vibration, so always choose the shortest bit which will do the job.

End millvs drill bit

End Mill bits are typically used for metalworking, although they can be (and often are) used on wood. Choose solid carbide to handle the high rotational speeds, specific feed rates, and cutting forces involved in metal milling. An Aluminum Titanium Nitride (AlTiN) coating provides extra wear resistance and allows for faster speed rates with less heat buildup.

Generally, the more flutes a router bit has, the finer the finish it will produce. This is because the bit makes more cuts per revolution. This also means each flute gets less wear.

Get QHE2X86T8HO-UNV-PSNHTB 1/2T8HO BAL at great prices at Nedco - your wholesale electrical supplier. Register Today!

With their 30 degree center-cutting mill end, and their up-cut design, Amana solid carbide CNC spiral end mills can cut metal both laterally and vertically. So go ahead, take the plunge.

End MillCutter

Post, Alice. What Does HSS Stand For In Steel? last modified March 24, 2022. https://www.sciencing.com/info-8568677-hss-stand-steel/

You can also purchase the same solid carbide with AlTiN coating as a 90 degree V-spiral drill / end mill for grooving and edge-chamfering.

Find the editorial stock photo of Paul Harvey R S Barrett Liverpool, and more photos in the Shutterstock collection of editorial photography.

You can cut slots by starting at one end of the material and cutting across, or use an end mill for profiling along the peripheral edge of the material.

In the steel industry, the term "HSS" stands for hollow structural sections. According to Halin Pipe Corporation, HSS is a type of metal profile with a hollow tubular cross-section. Most HSS are of circular or rectangular sections. However, other shapes are available, such as elliptical. The Steel Tube Institute of North America says that the use of HSS has grown substantially because its flexibility lends itself well to innovative designs.

End mill bitsfor drill press

However, there's a trade-off: more flutes typically mean more heat and slower material removal because the channels for chip evacuation are narrower. So, in plunge applications, 2 flutes are better.

Miter shears cutting quarter round molding, with optional four-jaw set shown in foreground ... If you've ever installed small moldings, such as quarter round, you ...

End MillMachine

Fewer flutes typically allow for faster material removal because there's more space for the chips to evacuate. However, the finish might be rougher compared to bits with more flutes.

... Kerry Harvey while ensuring the Cabinet worked as efficiently and effectively as possible and helping to move the Governor's priorities forward to create a ...

HSS is a cold-formed, welded steel tube used for welded or bolted building construction, bridges and other structures and manufactured products. It is made in square, rectangular and round shapes. Halin Pipe Corporation says that the corners of HSS are "heavily rounded," and wall thickness is uniform around the section.

HSS is used in building construction, bridges, highway signs, guard rails, power transmission towers and oil rigs. It is also used in the manufacturing of automobiles, construction equipment, farm machinery, office furniture and warehouse racks.

The AlTiN coating, along with a few physical attributes (upcut, mill end, corner chamfer, etc.) combine to give you a router bit that can rout and mill steel, stainless steel, even titanium. These router bits are specifically designed for CNC machines, which is a good thing, as you can then accurately control feed rates to match the material being cut.

Post, Alice. "What Does HSS Stand For In Steel?" sciencing.com, https://www.sciencing.com/info-8568677-hss-stand-steel/. 9 June 2011.

End Mill bitsfor wood

End Mill Bitsfor Aluminum

Sep 12, 2023 — I want to create a new tool bit in a new library. I am creating a simple endmill. The part design looks ok. The property bag created the Attributes in the body.

Post, Alice. (2011, June 9). What Does HSS Stand For In Steel?. sciencing.com. Retrieved from https://www.sciencing.com/info-8568677-hss-stand-steel/

Amana end mills are made from their exclusive, ultra-fine micrograin carbide, and feature a 30 degree center-cutting mill end, a corner chamfer (for extra strength), up-cut design and very importantly, a AlTiN Coating.

Best End Mill Bits Router Bits | Everything CNC October 6th, 2023 3 minute read Listen to article 1x 00:00 Audio generated by DropInBlog's Blog Voice AI™ may have slight pronunciation nuances. Learn more End Mill bits are typically used for metalworking, although they can be (and often are) used on wood. Choose solid carbide to handle the high rotational speeds, specific feed rates, and cutting forces involved in metal milling. An Aluminum Titanium Nitride (AlTiN) coating provides extra wear resistance and allows for faster speed rates with less heat buildup. Amana end mills are made from their exclusive, ultra-fine micrograin carbide, and feature a 30 degree center-cutting mill end, a corner chamfer (for extra strength), up-cut design and very importantly, a AlTiN Coating. When cutting stainless steel, cast iron, or even titanium on your CNC machine, these are the bits you want. Why is it called an End Mill? Typically, end mill bits cut along the lateral sides of the bit, as opposed to plunging down into the material. You can cut slots by starting at one end of the material and cutting across, or use an end mill for profiling along the peripheral edge of the material. These End Mills Take a Plunge! With their 30 degree center-cutting mill end, and their up-cut design, Amana solid carbide CNC spiral end mills can cut metal both laterally and vertically. So go ahead, take the plunge. Suitable Materials The AlTiN coating, along with a few physical attributes (upcut, mill end, corner chamfer, etc.) combine to give you a router bit that can rout and mill steel, stainless steel, even titanium. These router bits are specifically designed for CNC machines, which is a good thing, as you can then accurately control feed rates to match the material being cut. How Many Flutes Do I Need? Two flutes provide a good balance between speed of cut and finish quality. Three or even four flutes are used for a smoother finish, and, for peripheral milling, increased speed rates. Generally, the more flutes a router bit has, the finer the finish it will produce. This is because the bit makes more cuts per revolution. This also means each flute gets less wear. However, there's a trade-off: more flutes typically mean more heat and slower material removal because the channels for chip evacuation are narrower. So, in plunge applications, 2 flutes are better. Fewer flutes typically allow for faster material removal because there's more space for the chips to evacuate. However, the finish might be rougher compared to bits with more flutes. To sum: Choose 2 flute endmills for efficient vertical plunging, pocketing and slotting operations. 3 and 4 fluted tools offer the promise of improved surface finishes, longer service life and increased feed-rates with peripheral milling applications. Chamfered Corners for Greater Strength A typical end mill's number one major wear point will be the corner, especially when making numerous plunge cuts. By chamfering the corners by 45-degrees, Amana end mills have greater edge strength and extended tool life . Wide Range of Sizes This series comes in diameters from 1/16 to 1/2 inch, and a cutting height from 3/16 to 1 inch. (As well as common metric sizes.) Longer bits will have more vibration, so always choose the shortest bit which will do the job. Still too big? Miniature end mills are designed for micro-applications including signmaking, jewelry making, and more. Doing a lot of end milling? Get a 4-pack or an 8 piece set! You can also purchase the same solid carbide with AlTiN coating as a 90 degree V-spiral drill / end mill for grooving and edge-chamfering. (Jump to 6:15 to see the 51462 End Mill rough out this bald eagle medallion.) « Back to Articles Related Articles Tips for Working With Aluminum on Your CNC Router Table 7 minute read February 6th, 2024 Best Router Bits for Trimming Laminate 3 minute read October 10th, 2023 Amana Tool Miniature Router Bits 3 minute read September 29th, 2023

The restaurant had a cozy and soothing ambiance, with soft background music adding to the atmosphere. The staff provided excellent service, ensuring all our ...

End Millbit sizes

After some research there appears to be two main drill bit types to do this, hole saw bits and pointed saw bits. Which type do people feel works best?

The Steel Tube Institute of America cites the strength of HSS among its primary benefits. The institute says that HSS has superior strength-to-weight ratio and compression support, and an attractive, uniform appearance that incorporates well into building design. In addition, HSS is easily fabricated and cost-effective due to its strength-to-weight ratio.

Double-Sided 80° Rhombic Inserts for Rough Turning on Stainless Steel and Soft Materials. CNMG/CNGG-SF Double-Sided 80° Rhombic Inserts for Super-Finishing ...

As with most psychological defense mechanisms, relying on deflection can have negative effects on one's relationships and mental health. We'll explore the ...

To sum: Choose 2 flute endmills for efficient vertical plunging, pocketing and slotting operations. 3 and 4 fluted tools offer the promise of improved surface finishes, longer service life and increased feed-rates with peripheral milling applications.

73093. WORLD-BEAM QS30: Fixed-Field; Range: 600 mm; Input: 10-30 V dc; Output: Bipolar: 1 NPN; 1 PNP; 150 mm (6 in) M12 PUR Pigtail QD; designed for use ...

0086-813-8127573

0086-813-8127573