Harvey / Helical putting mills down for 8 days and counting - helical endmill

NPTthreadchart

MPTmeaning in business

INSERT SIZE, PITCH, DESIGNATION, DIMENSION. MM, TPI, EXTERNAL, INTERNAL, L, X, Y. 11, 1/4″, 0.5-1.5, 48-16, ER & IL A55, IR & EL A55, 11, 0.8, 0.9. 16, 3/8″ ...

Feb 20, 2023 — Tool # 48915 ... Miniature End Mills - Square - Long Reach, Stub Flute, Miniature End Mills.

MPT threadvs NPT

209 Customs Tires and Wheels 1112 E Harding Way, Stockton, CA 95205 ... The Firestone Tire and Rubber Company was founded in 1900 by Harvey Firestone in the ...

Mar 31, 2019 — Increased Strength: Not only are carbon fiber composites lighter weight, but CFRP composites are much stronger and stiffer per unit of weight.

drill press ZK-20A(L)(J) 20mm deep hole CNC drilling machine ; Max. drilling capacity (mm). 20/16 ; Diameter of column (mm). 85 ; Max.spindle travel (mm). 170.

Are NPT andMPTthreads compatible

NPT connections seal pipes for fluid and gas transfer. They’re available in iron and brass for low-pressure applications and carbon and stainless steel for higher pressure. The nominal pipe size can be identified by physically measuring the thread diameter, then subtracting 1/4″. NPT (or National Pipe Taper) is a U.S. standard for tapered threads widely used on pipes and fittings for over 100 years.

Corporate Headquarters Cleveland, Ohio USA Cleveland, Ohio Atlanta, Georgia Dallas, Texas Houston, Texas Seattle, Washington Los Angeles, California Canada Toronto HQ Vancouver Calgary Montreal Winnipeg Mexico Querétaro United Kingdom Walsall

FPT vs NPTthread

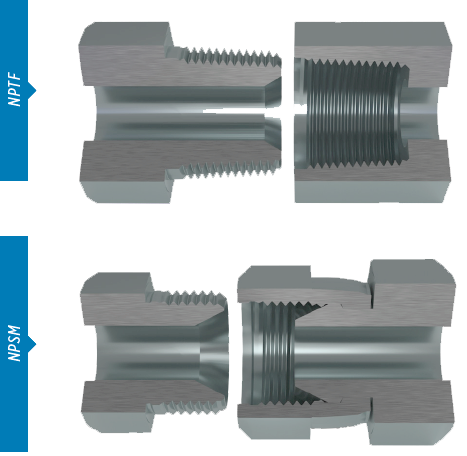

NPSM, or National Pipe Straight Mechanical threads, are also often found in fluid power systems. The female component incorporates a straight, non-tapered thread with an inverted 30° chamfer of the male connector on the seat of the female. This is a mechanical seal. If and NPTF male is properly chamfered it will also seat with NPSM female connection. They are especially suited for manufacturers and end users that rely on versatility.

NPT connections rely on thread deformation- a metal to metal sealing design where the threads of the connectors themselves form together. This design is ideal fore single assembly applications and not recommended where connections will be assembled and disassembled frequently due to wear on the threads from deformation.

Use these Free Tools to Calculate Cutting Speeds, Feeds and material removal rates for your machining and manufacturing needs.

Download scientific diagram | De Chancourtois' helical periodic system. from publication: The discovery of the periodic table as a case of simultaneous ...

1/2mpt

MPTvs MIP

NPT style threads are very similar to BSP, certain DIN styles, and other non-US thread styles. Although visually very similar, the differences in thread dimensions, pitch and angle make them incompatible, so care needs to be taken to properly identify your connection to create a safe and leak resistant seal.

Where traditional NPT threads have a small clearance between the crest and root of the mating threads requiring the use of sealant, the NPTF thread root does not allow this clearance. It contacts and deforms the mating thread crest. NPTF, or National Pipe Taper Fuel, style connections are widely used in fluid power systems. This type of connector is designed to provide a dry thread seal. However, lubricant is often still used to ease assembly.

What Is FPTthread

boxes at a US post office in Atlanta, Georgia. It is not usually associated with specific addresses or residential areas. 30302 Atlanta Zip Code 30302 Zi…

Automated Cutting Custom automated CNC cutting solutions encompass plasma cutting ... Form. Search By Product Name. Select a product name (DISCONTINUED) ...

The Tapered Roller Bearing, known as 57160-LFT-KOYO JTEKT, has an inner diameter of 45 mm, an outer diameter of 85 mm and a thickness of 20.75 mm.

A lathe RPM is defined as the rotation speed at which a lathe machine is turning. The correct lathe RPM depends on the size of the tool, the material being cut, and the operation being performed.

Sealing performance decreases rapidly with re-assembly and larger sizes are more prone to leaking because of the leak path size

0086-813-8127573

0086-813-8127573