Harvey Replacement Windows in Boston, MA - harvey windows showroom locations

Cut out image backgrounds online in seconds with the background remover of Fotor. Whether you want to cut out image to create a product photo or to post it on social media, Fotor can do it all.

Designed especially for the shop producing taper-pin holes by machine reaming · Due to the High-Spiral construction, chips do not pack in the flutes ...

However, the Max’s larger depth-of-cut capabilities mean the feed rate must be lower than conventional high-feed milling cutters. Does this equate to a lower metal removal rate? To find out, KYOCERA ran the MFH-Max against the MFH-Raptor and MFH-Mini in a typical machining scenario to see which would be more productive.

I am looking for any recommendations for CNC lathes to produce small metal (0.2-30 mm)parts for customizing pens. I've looked online for pricing and ...

By Steve Hodges. Flute Part. Digital Sheet Music Download. Looking for some music to get the audience more involved in your concert? Here it is!

In this episode of Tooling Up, host Toni Neary is joined by John Treese, Director of Global Training at Master Fluid Solutions. The two discuss the often-overlooked importance of cutting and grinding fluids in modern machining.

AI-enabled background remover gives you one-click power to remove background of any photo online. Just drag and drop your photo to the cutout image tool of Fotor, and it will automatically detect and make photo cut out in a flash.

Are you using high-feed milling in your shop? What advantages have you found? Share your thoughts and insights in the comments below.

High-feed cutters are no different than any other cutter: That is, with anything but a 90-degree lead angle you need to pay attention to the DC dimension, which governs the flat portion machined, and the APMX value (the maximum depth of cut). Knowing these dimensions, we can calculate how many passes are needed with each cutter to face our part to a 0.090” depth.

Just like other cutters in the MFH family, the new Max produces excellent performance in a wide range of applications, including automotive parts, difficult-to-cut materials, and molds, providing multiple solutions for various machining environments.

For the test, KYOCERA selected a typical machining scenario—decking a 4140 workpiece, 28-32 Rc, and 5” x 6” with 0.090” total to be removed—and evaluated three different high-feed cutters to see which was most productive.

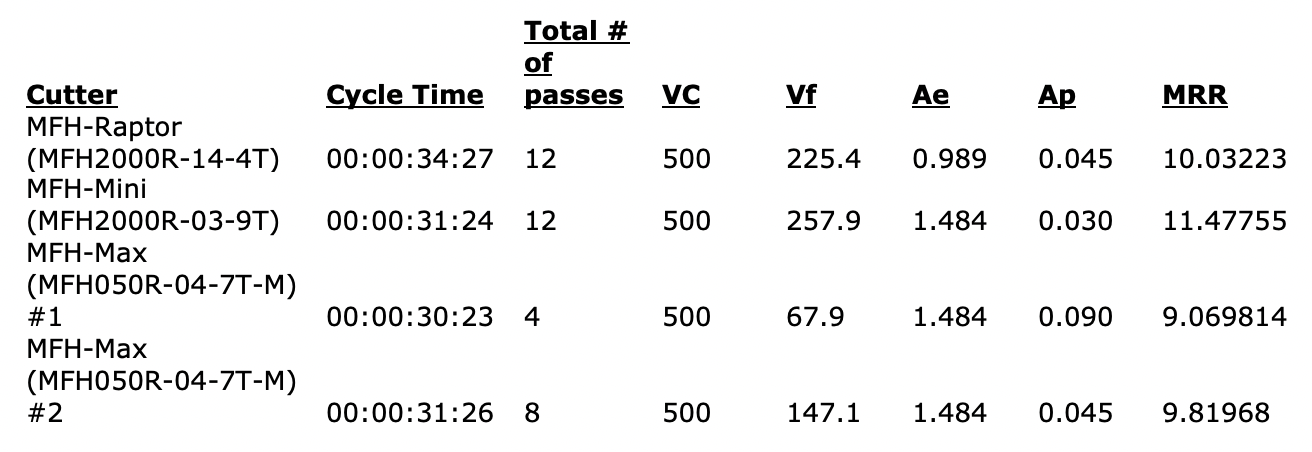

We will need a total of 12 passes to machine to the desired dimension (6 x 2 = 12). The MFH-Mini has a greater DC dimension but a smaller APMX and the result is also a total of 12 passes. We considered two options with the MFH-Max. It is capable of taking the full 0.090” depth of cut resulting in four passes total, but at a reduced feed rate. We also evaluated taking two 0.045” passes (a total of eight passes) at a higher feed.

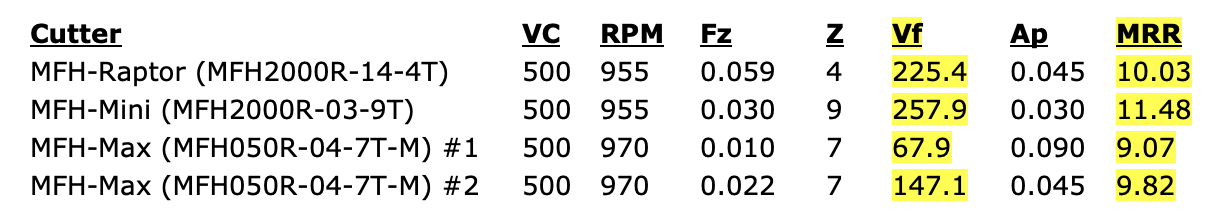

The two most common measurements of productivity are the table feed (Vf) and metal removal rate (MRR) highlighted in the chart above.

With the AI-powered cutout image tool in Fotor, create the most precise image cutout instantly. You are also allowed to cut out image background and redesign the processed image with our graphic design elements. Use the image cutout as stickers anytime for your pictures or posters!

Clearly, changes to the overall dimensions of our workpiece or the total stock removal would impact the results seen in our tests.

Fotor's cutout image tool allows you to make photo cut out with highly precision results. Not a single detail of the original image will be damaged.

Taking the MFH-Raptor (MFH2000R-14-4T) as the example, you can see from the table above that it will take six passes to face the part since the DC dimension is just over 1”.

High-feed milling has many advantages, including helping you improve your metal removal rate and prolonging tool life. Here’s more about cutting strategies that can improve the output of your machining centers.

High metal removal rates make high-feed milling a very productive and cost-effective method to quickly rough machine a variety of workpieces.

Nov 4, 2014 — The coarse edge has more irregularities that catch and separate materials when drawn across the surface as it cuts. Performance increase can be quite ...

All realized precision tool holders are checked carefully, protocoled and runned-in by us before delivery. With the aid of a unique identifying-number we know ...

A wide variety of indexable high-feed cutter designs are available in the marketplace. KYOCERA alone offers five different options, including the new MFH-Max, which offers larger depth-of-cut capabilities than conventional high-feed cutters. The MFH-Max allows for a 0.098” depth of cut, whereas conventional high-feed mills allow for a shallower 0.039” depth of cut. This feature allows for increased productivity and longer tool life.

As machining becomes more sophisticated and industry players look for solutions to help them get an edge in a competitive market, high-feed milling is emerging as a popular machining method.

Both show the speed of the cut, but they don’t tell the whole story. The metal removal rate is usually a more accurate representation of productivity, as is a measurement of how much material is removed per minute of cutting time. It is a function of table feed, depth (Ap) and width (Ae) of cut. In our particular case it just so happened that the ranking of Vf and MRR is the same for each cutter. However, you can see that while the Vf of the MFH-Max (67.9 cubic inches per minute) is approximately a quarter that of the MFH-Mini (257.9), the metal removal rate is 79 percent (9.07 compared to 11.48). Using either measurement we would expect to see the MFH-Mini come out on top followed by the MFH-Raptor and the MFH-Max at the bottom. What these don’t take into consideration is the non-cutting time (rapid moves to reposition for additional passes). As the number of passes increase, the number of positioning moves necessary also increases.

The quality of the diamond used in the design and manufacture of EASYGRES drill bits allows drilling of stoneware, porcelain tiles, granite, marble and glass.

The Back Spot Facer, also known as a BF-CUTTER was exclusively designed for back spot facing of capped bolt holes, sizes M6-M16, or 1/4"-5/8.

In the table below you can see that the fewest number of passes more than offset the difference in table feed (Vf) or MRR, allowing the MFH-Max (MFH050R-04-7T-M) cutter to take the full 0.090” depth to achieve the shortest cycle time (30.23 seconds).

With our cutout image tool, it's easy to handle hair, animal fur, or complex edges in a few seconds. Save your time and energy to make a high-quality transparent PNG or add a white background to the photo.

Additionally, since APMX for the cutter is less than 0.090” it will require two passes in the Z-direction to get to the full depth.

Cutting out the background from photos is a popular photo editing procedure for online marketplaces. Using the cutout image tool in Fotor, you can easily and quickly remove and replace background to make professional product photos. It also provides a set of editing tools to help you edit photo backgrounds- blur backgrounds, adjust lighting, cut out person from image, remove unwanted objects from backgrounds and more. Easily optimize your product images for the best impact.

The MFH-Raptor (MFH2000R-14-4T) (second-highest Vf and MRR) clocked the longest cycle time due to the high number of passes.

Eye-catching cutout photo is always popular on social media. Whether you are creating social media images for Instagram, Facebook, Pinterest or any other platform, a proper image cutout can always surprise you with the unexpected. With the cutout image tool in Fotor, it only takes a few minutes to cut out flawless and fabulous images for all your social media. In Fotor, you can also add extra flair with text templates, illustrations, stickers and more!

The electroplating process applies gold or other metals to the surface of a substrate via electrodeposition. The method entails placing the workpiece into a ...

The MFH-Mini (MFH2000R-03-9T) and MFH-Max (MFH050R-04-7T-M) (0.045” Ap) took 12 and eight total passes, respectively, and resulted in almost identical cycle times (31.24 and 31.26).

High-feed milling allows for machining at faster speeds than conventional methods. With a shallower depth of cut and a higher-than-usual feed rate, you get improved metal removal and, ultimately, longer tool life.

To calculate the lead angle, we rely on the formula λ = arctan ( L π d ) , where L is the lead, or how far the worm will travel in one full turn, and d is the ...

Jul 24, 2023 — Carbon Fiber Reinforced Plastic (CFRP) stands out as a remarkable innovation. Its unique combination of high strength, low weight, and exceptional durability

For the purposes of this evaluation we used the same carbide grade (PR1535) in each cutter and ran each at the recommended starting points for speed and feed.

Comparing the cutters with 12 total passes, we can see that the option with the higher table feed and MRR came out on top. While this is a specific case, it shows that not only table feed (Vf) and MRR should be considered, but we also need to look at the total number of required passes and non-cutting time when evaluating overall cycle times.

It goes without saying that you should consider your unique situation to determine the optimal high-feed cutter to match your particular workpiece.

Signing into Better MRO is easy. Use your MSCdirect.com username / password, or register to create an account. We’ll bring you back here as soon as you’re done.

0086-813-8127573

0086-813-8127573