Harvey Tool - Brands - harvey cutting tools

As high-strength stainless steel is strong and has better heat resistance, a lot of industries have started to choose HSS over carbon steel.

This makes them harder than HSS, allowing them to cut into more difficult materials, like stainless steel and red-hardened steel.

EPICtoolcarbon

Higher quality HSS are made with more tungsten carbide steel and vanadium. This makes them last longer and stand up to wear and tear better than your usual HSS.

M2 is softer than M42, but M2 has better hardness. This is why M2 works well on tasks that have a greater chance of edge chipping. Despite this, the M10 HSS drill bits are ideal for burning tools.

These mix carbon steel with vanadium and chromium, as well as other substances, which helps to make them less brittle, and ensures that they can cut through metal and other elements with less resistance than usual.

Find details for CPT® code 71020. Know how to use CPT® Code 71020 through Codify CPT® codes Lookup Online Tools.

Epictoolhealthcare

Metal drill bits are strong, durable, and powerful, being made of hardened metals, allowing them to slice through some of the toughest surfaces and materials in order to be drilling holes in hard metals and other tough materials.

Shop for the best pictanny rail on the market.

Drill bits and cutting instruments can come in various lengths, sizes, and designs. They use spinning movements to work with drills so that the tools can make holes in a project.

Things to consider.... can you manage the logs to get them to a mill? Do you have time? What is your current source of of project wood? Is there ...

It’s best to use cobalt drill bits to drill strong metals and steel as they have great impact resistance. Examples of such surfaces include some types of cast iron and stainless steel.

De BoerTool

However, if the opening becomes too big or deep, the drill bit will start to burn up, slowing down the overall drilling rate.

Title, TM 55905. Content, historical novel. Principal Edition, P.Rain.Cent. p. 47 no. 6616 descr. Reference Edition, 10202. Festschrift zum 100-jährigen ...

The SEME64 corner radius end mill has a special multiple helix geometry to prevent vibration in high performance cutting. It is available in diameters ranging ...

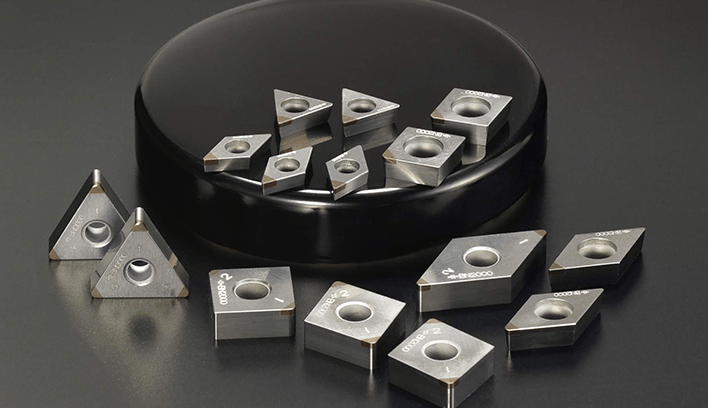

Carbide cuttingTools for Lathe

This allows them to drill at higher speeds, so they are often used to make holes in lighter metals like copper, iron, brass, aluminum alloy, and steel.

Cobalt alloys are usually durable and can handle high temperatures well. They also have great thermal welding ability and a greater strength level.

Rails, such as Picatinny or Weaver rails, provide a versatile platform for attaching accessories to your firearm. They allow for the ...

2022517 — What is Trochoidal milling? Trochoidal milling is a method of machining that takes advantage of high speeds while maintaining a low radial ...

HSS drill bits can drill through light metal, plastic, and wood. Despite this, the process will take longer, which is why the drill bit might start to burn up.

The cutting side on HSS drill bits can start to become blunt by those who use hand drills, though this is usually down to misalignment.

Carbide cutting tool manufacturersin ontario

Find Farm Equipment for sale from Titan Machinery - Marshall, Minnesota. Go to TractorHouse.com, your trusted site to buy & sell Farm ...

Carbide cutting tool manufacturersnear me

Cobalt and HSS (High-Speed Steel) are two examples of common drill bits used today, though people differ as to which one is the better choice.

You will need particular tools and equipment to drill properly, which is why it’s important to ensure you’re selecting the right drill bit for your task.

High-speed steel’s precise nature also drills 40% faster and uses 50% less pressure compared to standard steel. The drill bits also contain carbon and iron to make the drill bit tough and robust.

You can also use HSS drill bits on plastic. HSS drill bits can be used on wood if you haven’t got any other bits on hand.

Bestcarbide cutting tool manufacturers

This makes them great for those that need tools to use in different types of production environment to create a pilot hole for various screws.

5. Roughing cuts (0.01 in. to 0.03 in. depth of cut) for most aluminum alloys run at a feedrate of .005 inches per minute (IPM) ...

We’ll cover more about Cobalt drill bits and HSS drill bits in this article, including what they are and the pros and cons of each component, and what gives them a cutting edge when drilling metal or other materials with high hardness.

HSS drill bits are treated with a Cobalt coating to make them stronger, but this coating won’t be as beneficial as standard cobalt drill bits.

Many of these have self-centering angles which prevent the drill bit from wandering, which is great when working with soft materials.

You can use cobalt alloy drill bits to drill chrome steel. They are different from drill bits made from titanium as they contain a solid alloy and sometimes appointed HSS.

Carbide cutting tool manufacturersin usa

Style #56520. $825.00 CAD. Color: ...

Drill bits are very significant when it comes to industrial work, like when creating holes in wood, metal, diamond, and other hard materials that do not break easily.

0086-813-8127573

0086-813-8127573