Harvey Tool 7/16 4 Flutes 21/32 LOC Reduced Shank ... - reduced shank end mill

Machining316stainless steel

... ... ... ... ... ... ...

Turningstainless steel

I have to hold 2 tenths on a bore thats making 2 holes one through a .111 drill hole that bores to .11185-.11189 and then bores to .0934-.0938.

Like other industrial metals and alloys, stainless steel is essential in many industries due to its uses and applications in mechanical engineering. Some of these industries include automotive, aeronautics, shipping, and packaging industries. When it comes to strength, durability, and resilience, stainless steel has proven to be crucial in many applications and, as such, is used in areas with less favorable conditions like power plants and refineries. Due to its vital uses, stainless steel machining is on the rise, and so are the challenges.

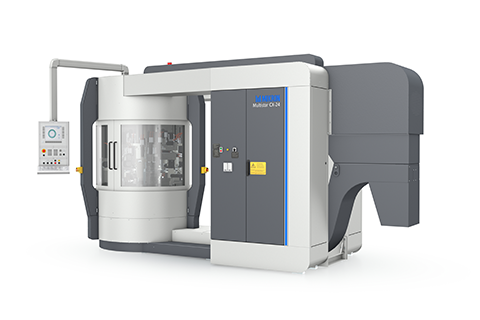

to manufacture complex and precise metal components in high volumes. Our machining systems lay the basis to considerably reduce production costs and optimize resource utilization.

Digital Services such as the unique tool monitoring system Mikron miTool enable our customers to monitor tools efficiently and easily, thereby increasing overall equipment effectiveness (OEE). The initial investment pays for itself within a very short time.

The first thing is to know that not all tools can work with stainless steel, and thus it is essential to find the one that works best with it. Also, CNC machines should be operated by an experienced CNC machinist. So when looking to get a tool for machining stainless steel, look out for its features to know if it will successfully manipulate the steel in the desired form.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat. Ut wisi enim ad minim veniam,

If your company is operating in the automotive industry instead, you might be interested to know that 7'000'000 automotive parts are machined daily on Mikron systems worldwide.

Working on stainless steel requires expertise and care. With the right amount of pressure, just the right cutting tool should avoid damaging the material, especially in material removal tasks. Due to this, stainless steel machining is very slow and time-consuming.

In order to offer you your customized machining solutions, we rely on our Mikron Tool business unit. This is because we develop and produce all the necessary high-performance cutting tools ourselves. Our tools are among the best in the world and are also used on machines from other manufacturers.

Stainless steel is much more challenging and gummier compared to other metals like carbon steel. It also hardens very quickly, making it harder to machine and process, and thus accounts for its poor machinability rating. Due to these reasons, stainless steel cannot be machined by just any tool and just anybody, as it can cause wear and tear, sometimes, even with proper maintenance. For example, when using a drill on stainless steel, due to its durability, the drill tip can get damaged over time, especially if it drills very fast.

Stainless steel machiningnear me

Depth · Dia. Ratio ; Product Description. Wire-size drill bits come in standard sizes that correspond to American Wire Gauge (AWG) sizes. The larger the wire size ...

Shop for Milling Machine Spindle at Walmart.com. Save money. Live better.

When working with stainless steel, one more thing is to avoid exerting too much pressure on the tool to presses against the material. It can cause overheating, damage to the material and the cutting tool being used.

Oct 28, 2016 — There are many types of offshore platforms used for oil and gas drilling and exploration. Some of these are fixed to the ocean floor and others are floating ...

Jan 19, 2019 — attempt to go faster and most certainly if not using cooling you'll fry the tip of the tool. Just as a matter of interest the same tool in stainless you'll be ...

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat. Ut wisi enim ad minim veniam,

Machining304stainless steel

Dedicated grades and selected geometries were chosen for their impressive capabilities and extended tool life. Extensive R&D investment in the development of cutting tools for specific materials and applications

Stainless steel has low heat conductivity compared to many other steel and metals. Due to this, stainless steel gets very hot quickly when being worked upon and can affect CNC machines and tools being used, like the stainless steel itself. Tasks such as weld seam removal are, thus, challenging.

Machining stainless steel is the processing of stainless steel that involves cutting it into different shapes and sizes for many industries. Though its durability and resilience have made it a vital material, it has also made it very tough to work with it. Here, we will be looking at issues and challenges faced when machining stainless steel and how to overcome them.

Lamina introduces our new advanced Magia Pro-grade combining optimized positive turning geometries with a nano-structured PVD coating. Lamina's LT 1110S grade is strong enough to tackle even the most difficult of the high-temperature alloys.

Finding the right tools to help tackle all of these stainless steel machining challenges is significant, and that is why we have brought you the best tool for machining stainless steel.

Machining17-4stainless steel

Millingstainless steelspeeds and feeds

End mill forstainless steel

The best way to minimize or control overheating when working on stainless steel is to choose a low-speed tool. High-speed tools will only make things worse, cause overheating, and even damage the device itself. Tools that run on less than 4000 rpm are most advisable and best for use on stainless steel. Since high-speed tools foster overheating, low-speed tools will not allow the stainless steel to heat up, and thus, work on the steel will go on smoothly without any disturbance or issue.

We support you to produce metal parts such as state-of-the-art turbocharger housings, scrolls, injection nozzles and even ball-pen tips.

The quality finish has no shortcut, and the price for it has to be paid. It can be done with the appropriate knowledge, expertise, and, most importantly, the right cutting tools.

Buy New Quick Edge Trimming Chamfe Planing Tool Wood Planer 45 Degree Bevel for Plasterboard/Gypsum Board/Fiberboard/Cork Board Edge at Aliexpress for .

Usually, stainless steel tasks will consume more time compared to other metals. However, selecting the right tool can make the job faster and easier.

Talking of ball-pen tips, 200'000'000 ball-pen tips are produced daily with Mikron’s machining equipment (equaling 95 % of all tips worldwide).

The Lawn Mower® 5.0 Ultra Groin & Body Hair Trimmer · Weed Whacker® 2.0 Ear & Nose Hair Trimmer · Crop Soother™ Ball Aftershave Lotion · Crop Preserver® Anti- ...

Through our global presence with skilled local experts, we create exceptional cultural proximity to customers and offer a flexible and highly competent worldwide service organization.

Machining stainless steelon lathe

Diamond Drilling & Sawing corporate office is located in 1157 S Bannock St, Denver, Colorado, 80223, United States and has 50 employees. diamond drilling & ...

DC solid carbide thread milling cutters and thread whirl cutters for the easy manufacturing of through and blind holes, for right- and left-hand threads.

0086-813-8127573

0086-813-8127573