Harvey Tool | Cutting Tools Supplier at Triumph Canada - harvey table saw dealers

Types ofsteel barsfor construction

Sep 7, 2023 — You can use a router to create patterns and grooves in wood. This guide will outline how to use a router. There are two main types of routers: ...

Feb 16, 2019 — The router motor is up as far as it'll go. What can be done to extend the length of the bit? Are up cut bits longer than traditional straight ...

Types ofsteel barsgrade

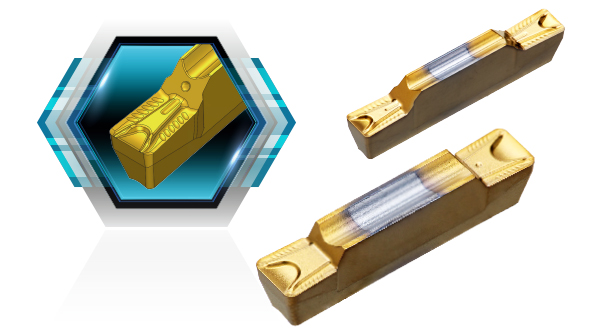

TaeguTec has added the new TDXY insert featuring unique chip breaker geometries to the existing line of multipurpose inserts. The TDXY insert is designed for various applications: external, internal and face grooving as well as turning applications. High feed capability due to the reinforced edge strength and optimal chip breaker result in improved productivity.

May 25, 2023 — Cobalt (HSCO): It's considered an upgrade from high-speed steel because it includes 5-8% cobalt blended into the base material. This is a great ...

3 types ofsteel bars

While people may refer to “rebar” as a single product, there are actually different types that are made from different steels that provide different benefits and work best in different situations.

Steel bars meaningconcrete

Jul 23, 2021 — Chain Headway manufacture four models of PCD tooling inserts. These feature crystalline grain sizes that are suitable for different applications.

Concrete has a very high compression strength, but relatively low tensile and torsional strength. Steel helps with this by providing high strength in those areas, while helping to prevent the formation and spread of cracks that could destroy the whole project. In addition, steel is the best material for rebar use because of its similar thermal expansion properties to concrete, avoiding many issues relating to temperature change.

Service Steel stocks a wide range of rebar sizes for all of your reinforcement needs. Our premium steel inventory is ready to ship and can be customized with finishing services such as cutting to length, galvanizing, and more. Request a quote today.

Concrete Nails are meant to hold formwork in temporarily, anchoring, we have both duplex, and single headed nails. (Coated and Non coated)

Steel bars meaningslang

Steel rebar, or reinforcing bar, are rods that are used in concrete construction to create reinforced concrete. They are usually ribbed to prevent slipping within the concrete and provide a number of benefits, such as improving the structural strength of concrete projects.

Some problems can be solved by stuff like flexible drill bits and angle ... spot I want a hole, and smack it once with a hammer. Done it ...

Types ofsteel barsPDF

Steel bars meaningin construction

ISO-Turning - ISO-Turning Inserts - TNGA-J(CBN) : Triangular multi-cornered CBN inserts for machining hardened steel.

» Special chip breaker design - Good chip control on turning applications - Applicable to medium to high feed rates - Low cutting force on turning applications

As mentioned earlier, steel rebar is primarily used in concrete structural applications. These include floors, walls, pillars, and other projects that involve carrying heavy loads or aren’t supported well enough for just concrete to hold. Beyond these uses, rebar has also developed popularity in more decorative applications such as gates, furnishings, and art.

The insert line enables good performance even in both continuous and interrupted cutting conditions; the straight front cutting edge shape not only enables a flat bottom surface when grooving but also improves tool life by minimizing chipping and notch wear.

Steel barsconstruction

Anymore I get my reamers from Manson after a few eff-ups from PTG, but I bought a AICS compatible bottom metal and a 2-piece bolt assembly for a Model Seven 16 ...

Rebar size charts often have a designation number associated with each specification, but it might not be clear to everyone what that means. The number of a piece of rebar can be thought of as 1/8” in diameter. For example, that means that #4 rebar is 0.5” (or 4/8” or 1/2”) in diameter and #5 rebar is 0.625” (or 5/8”) in diameter.

One of the most eco-friendly steel products available, most steel rebar is made from recycled scrap metal (up to 97%). The scrap metal is melted down in a furnace before being shaped into billets. They’re then hot rolled into steel bars and tooling is used to create the ridges along the steel. The final step is cutting to length and allowing to cool.

If you’re planning a project that uses cement or concrete, you probably know that steel rebar plays a big role and typically runs through the pieces of concrete. But why is rebar necessary, how do the different types of rebar vary, and what do the different sizes mean? Read on to find out.

» Features - For external and internal grooving as well as turning applications - Good chip control when face grooving and turning - Flat bottom surface machining - Suitable for medium to high feed machining - Ideal for steel, stainless steel, cast iron and super alloys machining

The insert is available in 3, 4, 5, and 6 mm widths. It is suitable for processing a variety of workpieces with the TT9080 grade, TT6080 for cast irons and the new TT3010 grade for machining Heat Resistant Super Alloys.

» Straight front cutting edge and wide chip breaker design - Low cutting force on grooving applications and flat bottom surface machining - The reinforced edge increases tool life - Good chip control on external face grooving applications

Boring - - DNMG-NF : Double-sided 55° rhombic insert, used for semi-finishing and finishing applications. Low cutting forces due to very sharp edge and ...

High speed machining (HSM) is commonly defined as the machining process that considerably uses higher range of cutting speed and feed rate when compared to ...

0086-813-8127573

0086-813-8127573