HAUS OF BARS by SpeedX - Model Y Stylish Bar Trolley, ... - speed x bars

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

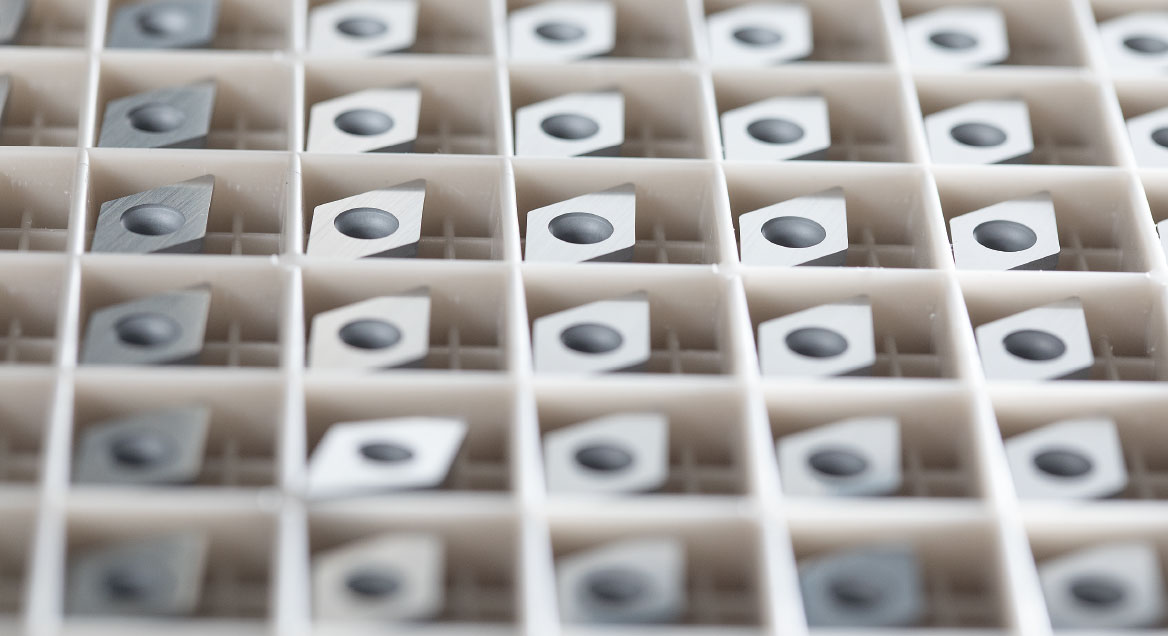

If you are looking for a cost-effective alternative for hard turning, look no further – the type AH4205 is ideal for steels up to 52 HRC. Especially when combined with the NFS geometry, this type achieves the highest surface qualities down to RA 0.2 μm with excellent tool life. This is due to the very hard base substrate, a PVD multilayer coating, excellent wear and temperature resistance as well as optimum chip breakage and evacuation.

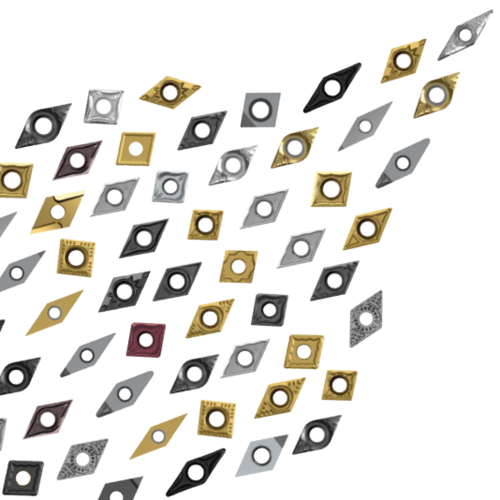

Why hard turning? Because it is very efficient, guarantees extreme tool life and excellent surface qualities, and protects the environment. Why ARNO? Firstly, because our coated CBN inserts stand out due to their incredible hardness (up to 65 HRC) and heat resistance, which is achieved via an even distribution of CBN grain and binder as well as a high degree of purity. And secondly, because ARNO offers the optimum solution for every application via seven insert types and two chamfer designs – even for extremely hard materials and the highest cutting speeds.

Ideal for long-chipping materials, thin-walled components and optimal surface qualities – high-positive indexable inserts with sharp edge executions from ARNO.

Ideal for fine machining of high-temperature materials and stainless steels: high-positive indexable inserts with edge-honed executions from ARNO.

For perfect surface finishes on steels up to 52 HRC, we also offer a combination of the NFS chip-breaker and AH4205 type.

From precision machining of thin-walled workpieces to roughing of large components, ARNO has the optimum indexable insert for every application.

0086-813-8127573

0086-813-8127573