HD 34445 Overview - 34445

During an operation, the most extended contact length should determine the end mill’s cut size. Ensure that this only lasts as long as necessary. Minimizing overhang, increasing rigidity, and reducing chatter will be achieved by selecting the shortest tool. To avoid making long cuts in applications that require a depth greater than 5x the tool diameter, it may be best to explore necked reach options instead.

As a result of their limited capabilities, regular carbon steel is usually not an option. Consequently, when it comes to getting the job done at a very reasonable price, HSS (high-speed steel) is the best choice. Furthermore, because of the rate at which it wears out, other options may be better if the product is used for an extended period.

Among them, cobalt-bearing HSS can be milled at even faster speeds than HSS without cobalt. As a result, most jobs can be performed with them, making them suitable for most applications.

Your CNC machining tool has a coating of some kind that also affects the way it performs. A layer, such as titanium nitride can extend the tool’s lifetime, but the cost of the coating also increases. Some types of coatings can also reduce the amount of lubricant needed during the use of your tool since they make it less sticky.

Are you new in the industry of milling? Or are you having a tough time recognizing the type of milling? You may need to consider working hard on your milling knowledge. Out of the most common milling tools, there are roughing end mill and finish end mill. They may seem similar to many people, or you can say to people who are beginners or who do not have knowledge about it. However, if you want to progress in the industry and know the clear distinction between both, I recommend you read the blog till the end. In this blog, we will thoroughly look at the difference between roughing end mill and a finishing end mill.

Selling Unit : Single itemSingle Package Size: 14×6×1.8cmPackage Type : 1. 10 pcs in a plastic box2. All order packed in carton box

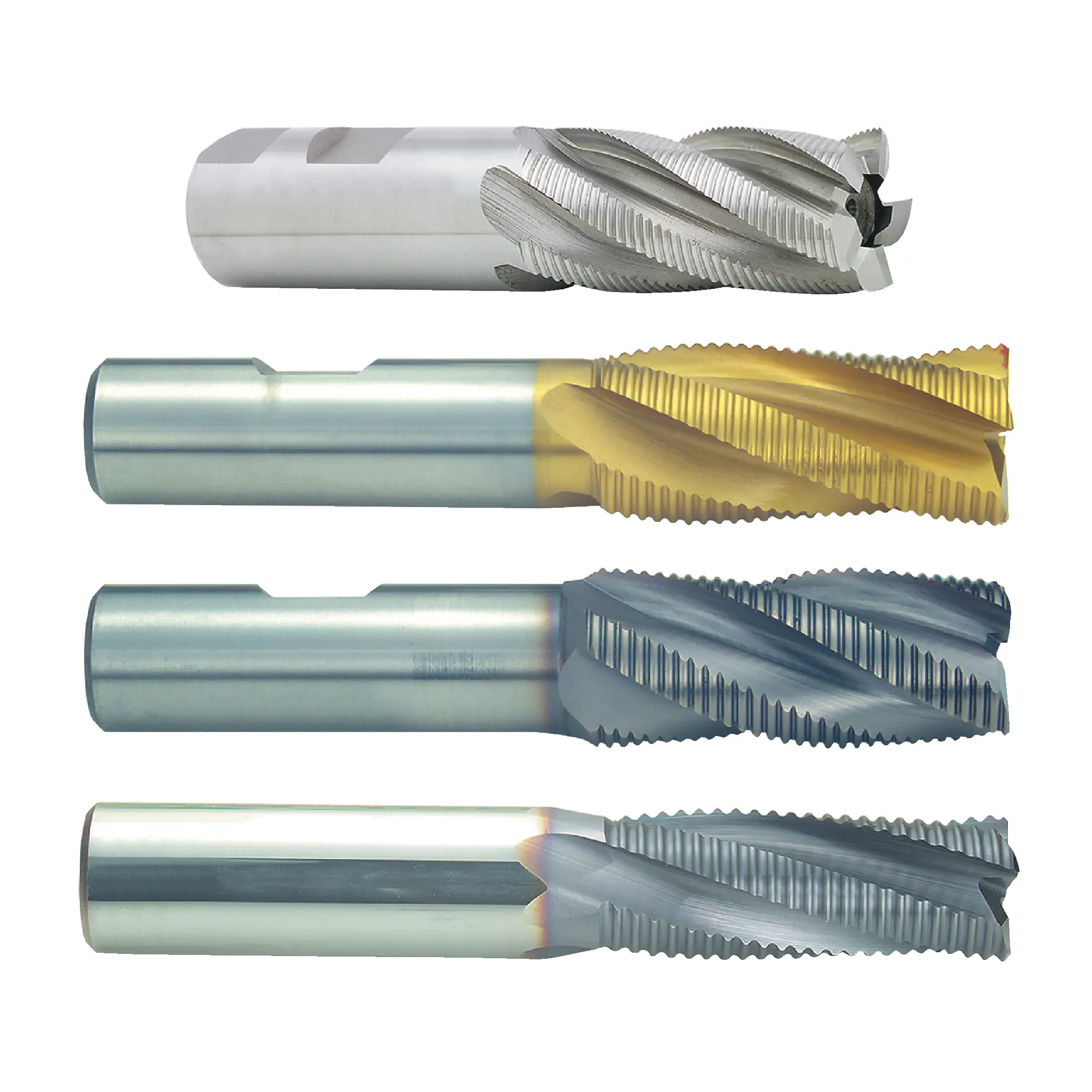

Compared with standard end mills, roughing end mills remove much more metal, including large amounts, quickly and efficiently. When used to remove stock from low to medium carbon steel or alloy steel before finishing, coarse tooth end mills remove large chips from heavy cuts, deep slots, and rapid stock removal. When cutting high-temperature alloys and stainless steel, fine tooth roughing end mills remove less material but apply pressure to many more teeth, ensuring longer tool life and a smoother finish. Metal chips break into smaller segments due to scallops on the outside diameter of these mills. Cutting pressures are therefore lower at a given radial depth. When large amounts of material need to be removed, they are used mainly to rough mill it off. AlTiN or ZrN PVD coating is often applied to carbide, cobalt, and HSS substrates. In terms of pitch, they are available in coarse, medium, and fine varieties. Long, extra long, and stub versions are available. Since the milled materials differ widely, helix angles and flute configurations also vary. They come in a wide variety of diameter sizes from 1/8″ to 3″.

In addition to being smooth as traditional end mills, finishing end mills have the advantage of rapidly removing large amounts of material. A two-step hogging/finishing process takes longer, while this process saves time. Resharpening tools will extend their life without modifying their shape. We offer a wide range of coatings, tool materials, and flute numbers to meet most machining requirements. One square end and a smooth outside diameter characterize a finishing end mill. There are a different number of flutes and helix angles on each helix. These tools are mainly used for side milling operations.

A rough cut is applied to impart a basic shape according to desired characteristics as a first step. It is not essential here to consider surface roughness; instead, removing the most significant amount of unwanted material from the surface is more important. In contrast, finishing passes are performed to improve surface quality, dimensional accuracy, and tolerance. Finish passes do not take into account stock removal rates.

Express Way: 1. Ship by our cooperated agent. Will chose the cheapest express within FEDEX, DHL, UPS, TNT, EMS.2. Your own agent in China or your own courier account.

Concerning the properties mentioned above of such milling machine tools, cemented carbide is another step toward high-performance milling. The up-front costs are higher but more cost-effective in the long run.

Unlike drill bits, End Mills rotate horizontally or laterally (side-to-side) rather than vertically. Material and surface finish should be considered when selecting endmills. Many types, sizes, and flute shapes are available. Using it, you can slot, profile, contour, counterbore, and ream. End mills are also used for engraving designs, cutting plastic, making molds, and making circuit boards, in addition to cutting precision parts.

During rotation, the cutter’s cutting edges form a slot whose width is determined by its diameter. The smaller the cutter diameter, the greater the clearance within tight pockets, and the larger the tool, the greater the rigidity for jobs with high volumes. If the cutter diameter is selected incorrectly – either too large or too small – the job can’t be completed, or the final part won’t meet specifications.

We are a subsidiary company established in 2020 in Guangzhou for export promotion, who is reponsible for entertaining our foreign customers and arranging the export of Tungsten Carbide Tools.Our company is committed to the research and development of new materials for cutting inserts and the localization of cutting inserts, specializing in the design and production of cemented carbide turning inserts, indexable inserts, CNC inserts (tools), vertical milling cutters, special inserts and non-standard shaped Products, etc., are emerging companies in cemented carbide cutting inserts. Considering the same production technology of Tungsten Carbide Tools, we expanded our products line with our customers gradually From carbide insert to carbide burrs, carbide end mills....... and some custome tools. And in order to reduce the time cost and transportation cost of our customers, we also help our old customers to buy tool holders and other products that are not part of our production at a cost-effective price from our cooperative factories.Over the two decades years since the company was established, through the hard work of all employees, R&D investment and equipment transformation, the company's production capacity has been continuously expanded, market share has been continuously expanded, and independent development capabilities have been continuously enhanced. At present, it has thousands of different types of cemented carbide Blade, a complete cemented carbide production and testing line has been established. The company has advanced production and testing equipment, regards quality as its life, insists on controlling problems at the source, and has established a set of internal management systems that pass customs, strictly refer to the international advanced enterprise standards for management and control, and passed ISO9001:2008 quality System certification has established a good corporate image in the industry. Adhering to the corporate philosophy of "being honest and doing things practically". Adhere to the business tenet of "Quality First, Customer First, Honesty First, High Quality Service", and constantly develop core technologies. Jianxing promises to "create value for customers", brave challenges, independent innovation, and wholeheartedly provide customers with high-quality products and perfect services.

Main Products: Tungsten Carbide Tools, Carbide Inserts, Carbide Slitters, Carbide Burrs, Carbide Rotary Files, Carbide Rozors, Carbide Wear Parts, Carbide Cutting Tools, Carbide Blades, Carbide Woodworking Tools

In addition to delivering excellent chip evacuation, helix four- and five-fluted routers have a multi-layer AlCrN coating to provide extended tool life. High feed rates and high speed are designed into the tool geometry. Besides having a radius on the corners, sizes are available in standard lengths and extended reach to accommodate milling in tight spaces.

Almost every conventional machining process results in the appearance of scallop marks or feed marks due to the velocity of the feed. Roughness on the surface is caused by scallop marks similar to saw teeth. The feed rate is the only factor directly responsible for surface roughness other than tool geometry. The surface finish of a product can be negatively affected by a higher feed rate. A higher depth of cut also degrades surface finish and machining accuracy. As a result of rough cutting, more excellent feeds and deeper cuts are utilized, resulting in poor surface finishes. It also does not meet the requirements for close tolerances and high dimensional accuracy. By contrast, finish passes require very low feeds and shallow cut depths, improving finish, accuracy, and patience.

Surface finishing helps to improve surface finish, tolerance and minimize errors. Roughing is primarily used to remove excess material from a piece. In addition, roughing is conducted at a higher feed rate and a deeper cut depth. A roughing process also removes more material than a finishing process.

It is the degree of roughness that determines the degree of demand placed on the inserts as well as the cutting angles. Surface finish is usually improved by using positive rake inserts when finishing machining. Some aspects of negative rake inserts make them most suitable for rough machinings, such as absorbing cutting forces, which makes higher cutting speeds possible.

End mills are most commonly designed with a square, corner radius, or ball profile. There are 90-degree angles on the corners of the flutes on a square profile end mill. By replacing the fragile sharp corner with a radius, corner radius profiles prolong tool life, adding strength and preventing chipping. Lastly, a ball profile is a profile that has flutes without a flat bottom and is rounded off at the end. An end mill with this style is considered to be the strongest. Unlike a sharp edge on a square profile end mill, an entire rounded cutting edge has no corners and removes the most likely failure point from the tool. Part requirements are often considered when choosing an end mill profile, such as square corners within a pocket, which require a square end mill. Consider using a tool with the most effective corner radius possible when designing your part. Corner radiuses are recommended whenever they are allowed by your application. Use a corner radius tool for rough corners, then finish with a square profile tool if square corners are necessary.

1.Advanced Equipment: Our workshop is fully equipped with spray tower, ball mill, automatic press, low pressure sintering furnace, tool grinder, CNC grinder and other equipment.2. Cost-effective price: Cooperate with LONBOND and OERLIKON coating companies to ensure that your products are beautiful and have a longer tool life.3.Advanced testing equipment: include hardness tester, density meter, high-power microscope, magnetic tester, metallographic tester, etc. 4.Clean and tidy environment: Managed in strict accordance with ISO9001 and 6S standard systems, scientifically and comprehensively control every link in the production process, guarantee product quality while efficient production, and provide customers with high-quality products.5. Competitive shipping charge: Have cooperated with our shipping agent for more than 10 years. They can give us competitive price to save your money...........................................................................................For more type or grade recommendation, welcome to contact us.

Choosing the right tool is essential when performing CNC machining, as it is a critical factor in the project’s success. The CNC machining needs of Huana Tools are more efficient than those of other companies. You must know which tool to use in each position since every position requires a different tool.

High-quality tools should be designed when milling at high speeds and temperatures (which can cause premature tool wear). Coatings should also resist oxidation at such high temperatures since oxygen becomes reactive. By combining fine-grade substrates with the coating, both toughness and hardness are simultaneously increased.

An abrasive milling bit consists of channels called flutes. An angled milling bit’s feed rate is determined by how many flutes it has. The downside is you’ll end up with a significant milling bit, leaving fewer spaces for metal bits cut off from the workpiece due to a high number of flutes.

A great deal of emphasis should also be placed on edge preparation. A homogeneous, deliberately rounded-off cutting edge prevents cracks from forming, minimizes wear, and ensures even abrasion. Various materials can be machined with milling cutters that possess these characteristics.

It will help you narrow down your end mill selection considerably if you know the material you are working with and its properties. Mechanical properties determine how a material behaves when machining and every material has unique characteristics. The machining strategy is different for plastic materials, and the tooling geometries differ from steel ones. Tool performance and longevity will improve by choosing tools with geometries suited to those unique characteristics.

The surface quality produced by both the end mills is better if we compare that of the roughing and finishing process. Unlike roughing, finishing can provide high dimensional accuracy and close tolerance, whereas roughing cannot.

0086-813-8127573

0086-813-8127573