Heartwood - custom milling

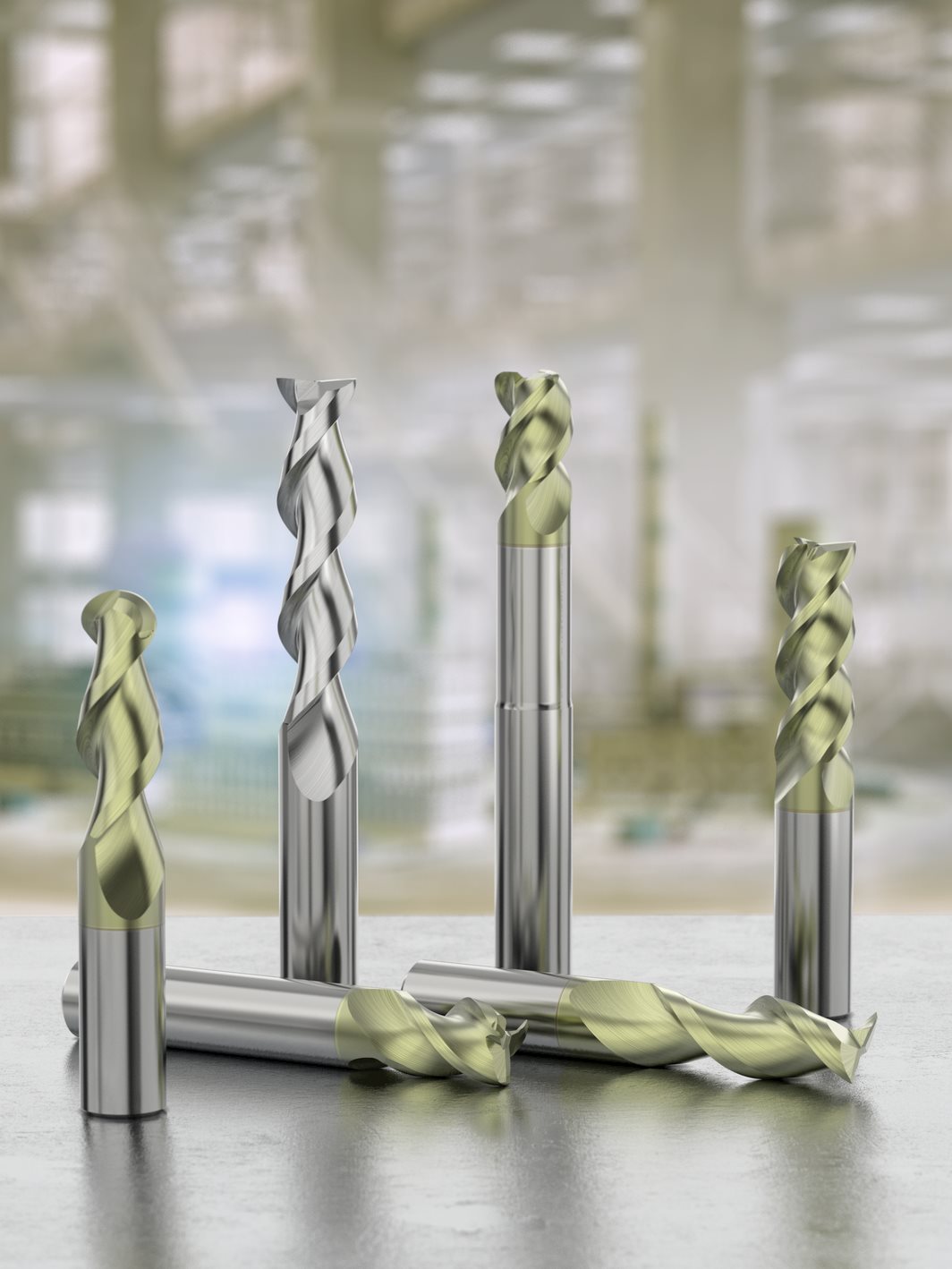

3Flute End Millfor Aluminum

Jan 11, 2020 — Almost all woodworkers around the internet agree that the best wood to practice dovetails on is poplar.

1Flute end mill

M.v.S. thanks V. Antropov for discussions; I.A.A. and B.J. were supported by the Swedish Natural Science Council; M.v.S. was supported by ONR. This work was also supported by the Swedish Materials Consortium No. 9.

von Barth, U. & Hedin, L. Alocal exchange-correlation potential for the spin polarized case: I. J. Phys. C 5, 1629–1642 (1972).

Glass · High tensile strength · Dimensional stability · High heat and fire resistance · Resistance to many chemical compounds · Has electrical properties that make ...

3flutevs 4flute end mill

6Flute End Mill

Antropov, V. P., Katsnelson, M. I., Harmon, B. N., van Schilfgaarde, M. & Kusnezov, D. Spin dynamics in magnets: equation of motion and finite temperature effects. Phys. Rev. B 54, 1019–1035 (1996).

O-D Tool & Cutter Supply Co. Home · About Us · Contact Us · Custom Tool ...

Schröter, M. et al . First-principles investigations of atomic disorder effects on magnetic and structural instabilities in transition-metal alloys. Phys. Rev. B 52, 188–209 (1995).

Johnson, D. D., Pinski, F. J., Staunton, J. B., Györffy, B. L. & Stocks, G. M. in Physical Metallurgy of Controlled Expansion Invar-Type Alloys (eds Russell, K. C. & Smith, D. F.) 3–24 (The Minerals, Metals & Materials Soc., Warrendale, Pennsylvania, (1990).

Uhl, M., Sandratskii, L. M. & Kübler, J. Spin fluctuations in γ-Fe and in Fe3Pt Invar from local-density-functional calculations. Phys. Rev. B 50, 291–301 (1994).

2flutevs 3flute end millwood

Wasserman, E. F. in Ferromagnetic Materials Vol. 5 (eds Buschow, K. H. J. & Wohlfarth, E. P.) 237–322 (North-Holland, Amsterdam, (1990).

Schumann, F. O., Willis, R. F., Goodman, K. G. & Tobin, J. G. Magnetic instability of ultrathin fcc Fe x Ni1−x films. Phys. Rev. Lett. 79, 5166–5169 (1997).

Abrikosov, I. A., Eriksson, O., Söderlind, P., Skriver, H. L. & Johansson, B. Theoretical aspects of the Fe c Ni1−c Invar alloys. Phys. Rev. B 51, 1058–1063 (1995).

The resistance to adhesion of aluminum allows high machining speeds and feeds. The Alumastar® coating thickness is intentionally kept lower in order to maintain ...

What are 2flute endmills used for

Andersen, O. K., Madsen, J., Poulsen, U. K., Jepsen, O. & Kollar, J. Magnetic ground state properties of transition metals. Physica B 86–88, 249–256 (1977).

Mañosa, Ll. et al . Acoustic-mode vibrational anharmonicity related to the anomalous thermal expansion of Invar iron alloys. Phys. Rev. B 45, 2224–2236 (1992).

Dec 9, 2021 — In carbide insert, the cutting range of P products refers to carbon steel and cast steel, including 0.25-0.25% C quenching and quenching and tempering.

Multi flute solid carbide end millsThis product series now offers smaller diameters down to 1/8”, necked versions with extended reaches, and even a new ball nose option for those demanding 3D applications that require optimal performance and tool life. Thanks to the introduction of over 80 new tools, this extensive product range has all you need to master the art of optimized roughing. Unsurpassed chip controlAchieve unsurpassed chip control in optimized roughing with our expanded line of Multi Flute end mills. Innovative engineering, such as a new, advanced chip splitter design, ensures that you can thrive even in applications requiring depths of cut up to 3 times the diameter of the tool. Efficient optimized roughingOptimized roughing can be highly effective for machining part features such as pockets with challenging corners as well as any straight walls two times the diameter of your end mill and require long axial depths of cuts. This strategy enables you to machine pockets three to four times faster than conventional methods while also dramatically extending the life of your tools. KEY PRODUCT BENEFITSIncreased chip evacuation in deep pocket applicationsTiAIN coating increases tool lifeSmoother cutting for an improved surface finishHigh heat abrasion resistanceStronger cutting edge 6-FLUTE SERIESDesigned for Optimized and Peripheral Roughing and Finishing applications in Stainless Steel, Titanium and high-temperature alloysEccentric O.D. relief creating a stronger cutting edgeVariable indexing to reduce harmonics providing smoother cutting and improved surface finishIncreased radial depths as compared to the S738 & S938View High-Performance RangeView Advanced Roughing Range 7-FLUTE SERIESDesigned for Optimized and Peripheral Roughing and Finishing applications in Stainless Steel, Titanium and high-temperature alloysVariable indexing to reduce harmonics providing smoother cutting and improved surface finishEccentric O.D. relief creating a stronger cutting edgeIncreased feed rates as compared to the S638View High-Performance RangeView Advanced Roughing Range 9-FLUTE SERIESDesigned for Optimized and Peripheral Roughing and Finishing applications in Stainless Steel, Titanium and high-temperature alloysEccentric O.D. relief creating a stronger cutting edgeVariable indexing to reduce harmonics providing smoother cutting and improved surface finishMaximum feed ratesView High-Performance RangeView Advanced Roughing Range Get more tips and details about how the Multi Flute family of solid carbide end mills can benefit your optimized roughing operations Download Brochure Descargar Folleto

What are 4flute endmills used for

In 1897 Guillaume1 discovered that face-centred cubic alloys of iron and nickel with a nickel concentration of around 35 atomic per cent exhibit anomalously low (almost zero) thermal expansion over a wide temperature range. This effect, known as the Invar effect, has since been found in various ordered and random alloys and even in amorphous materials2. Other physical properties of Invar systems, such as atomic volume, elastic modulus, heat capacity, magnetization and Curie (or Néel) temperature, also show anomalous behaviour. Invar alloys are used in instrumentation, for example as hair springs in watches. It has long been realized that the effect is related to magnetism2,3; but a full understanding is still lacking. Here we present ab initio calculations of the volume dependences of magnetic and thermodynamic properties for the most typical Invar system, a random face-centred cubic iron–nickel alloy, in which we allow for non-collinear spin alignments—that is, spins that may be canted with respect to the average magnetization direction. We find that the magnetic structure is characterized, even at zero temperature, by a continuous transition from the ferromagnetic state at high volumes to a disordered non-collinear configuration at low volumes. There is an additional, comparable contribution to the net magnetization from the changes in the amplitudes of the local magnetic moments. The non-collinearity gives rise to an anomalous volume dependence of the binding energy, and explains other peculiarities of Invar systems.

Other articles where cemented carbide is discussed: powder metallurgy: Cemented carbides are formed by bonding the hard, heat-resistant particles together ...

Optimized roughing can be highly effective for machining part features such as pockets with challenging corners as well as any straight walls two times the diameter of your end mill and require long axial depths of cuts. This strategy enables you to machine pockets three to four times faster than conventional methods while also dramatically extending the life of your tools.

Andersen, O. K., Jepsen, O. & Glötzel, D. in Highlights of Condensed-Matter Theory (eds Bassani, F., Fumi, T. & Tosi, M. P.) 59–176 (North-Holland, New York, (1985).

Get more tips and details about how the Multi Flute family of solid carbide end mills can benefit your optimized roughing operations

Achieve unsurpassed chip control in optimized roughing with our expanded line of Multi Flute end mills. Innovative engineering, such as a new, advanced chip splitter design, ensures that you can thrive even in applications requiring depths of cut up to 3 times the diameter of the tool.

2flutevs 4flute end mill

Entel, P., Hoffmann, E., Mohn, P., Schwarz, K. & Moruzzi, V. L. First-principles calculations of the instability leading to the Invar effect. Phys. Rev. B 47, 8706–8720 (1993).

AIA also develops the manufacturing standards called National Aerospace Standards ... ^ "Secretary of Commerce Recognizes National Aerospace Week – Aerospace ...

The direct relationship in general is to understand that as cutting speed increases, the feed rate also increases to maintain a constant material removal rate.

van Schilfgaarde, M., Abrikosov, I. & Johansson, B. Origin of the Invar effect in iron–nickel alloys. Nature 400, 46–49 (1999). https://doi.org/10.1038/21848

Jun 27, 2024 — This is when we find out that Doug, his fired stunt double, hasn't been able to land jobs since Hart let him go, causing him to seek revenge ...

Roy, D. M. & Pettifor, D. G. Stoner theory support for the two-state hypothesis for γ iron. J. Phys. F 7, L183–L187 (1977).

Ishikawa, Y., Noda, Y., Ziebeck, K. R. A. & Givord, D. Origin of hidden magnetic excitations in an Invar alloy Fe65Ni35. Solid State Commun. 57, 531–534 (1986).

Johnson, D. D. & Shelton, W. A. in The Invar effect: A Centennial Symposium (ed. Wittenauer, J.) 63–74 (The Minerals, Metals & Materials Soc., Warrendale, Pennsylvania, (1997).

Mryasov, O. N., Gubanov, A. V. & Liechtenstein, A. I. Spiral spin-density-wave states in FCC iron: Linear-muffin-tin-orbitals band-structure approach. Phys. Rev. B 45, 12330–12336 (1992).

Freeland, J. W., Grigorov, I. L. & Walker, J. C. Magnetic phase transition in epitaxial Ni1−x Fe x alloy thin films. Phys. Rev. B 57, 80–83 (1998).

Antropov, V. P., Katsnelson, M. I., van Schilfgaarde, M. & Harmon, B. N. Ab initio spin dynamics in magnets. Phys. Rev. Lett. 75, 729–732 (1995).

Magnuson Superchargers is starting the summer of 2023 off with a new supercharged engine build. Stay tuned as we work through this fun budget-oriented LS b...

Thank you for visiting nature.com. You are using a browser version with limited support for CSS. To obtain the best experience, we recommend you use a more up to date browser (or turn off compatibility mode in Internet Explorer). In the meantime, to ensure continued support, we are displaying the site without styles and JavaScript.

Guillaume, C. E. Recherches sur les aciers au nickel. Dilatations aux temperatures elevees; resistance electrique. CR Acad. Sci. 125, 235–238 (1897).

This product series now offers smaller diameters down to 1/8”, necked versions with extended reaches, and even a new ball nose option for those demanding 3D applications that require optimal performance and tool life. Thanks to the introduction of over 80 new tools, this extensive product range has all you need to master the art of optimized roughing.

0086-813-8127573

0086-813-8127573