Hidalgo Cad: Complete with ease - hildalgo cad

Tapdrillsizechart mm

Metric threads of the International Standards Organization (ISO) have the same 60-degree thread form as UN threads, though the diameters and pitches are not interchangeable. Metric tap drill charts have the same drill size problem in that they use the same formula as that employed for the obsolete AS threads. In both ISO and UN thread series, having a range of useful drill sizes allows designers and machinists to tailor effective thread depth for long holes, various materials and thread strength requirements. It also allows for the combining of inch and metric taps and drills where convenient to do so.

CVD Diamond Coating provides excellent wear resistance and tool life. Diamond coating has superior tool life improvement over carbide, depending on the grade of coating:

Tapdrillsizechart

For over 25 years, National Diamond Tool and Coating has helped industries like yours succeed with the right tools for every job. Whether you choose diamond-tipped, diamond-coated, or diamond grit coated diamond tools for your job, you can rest assured that the tools you source from us will make your processes quicker and easier.

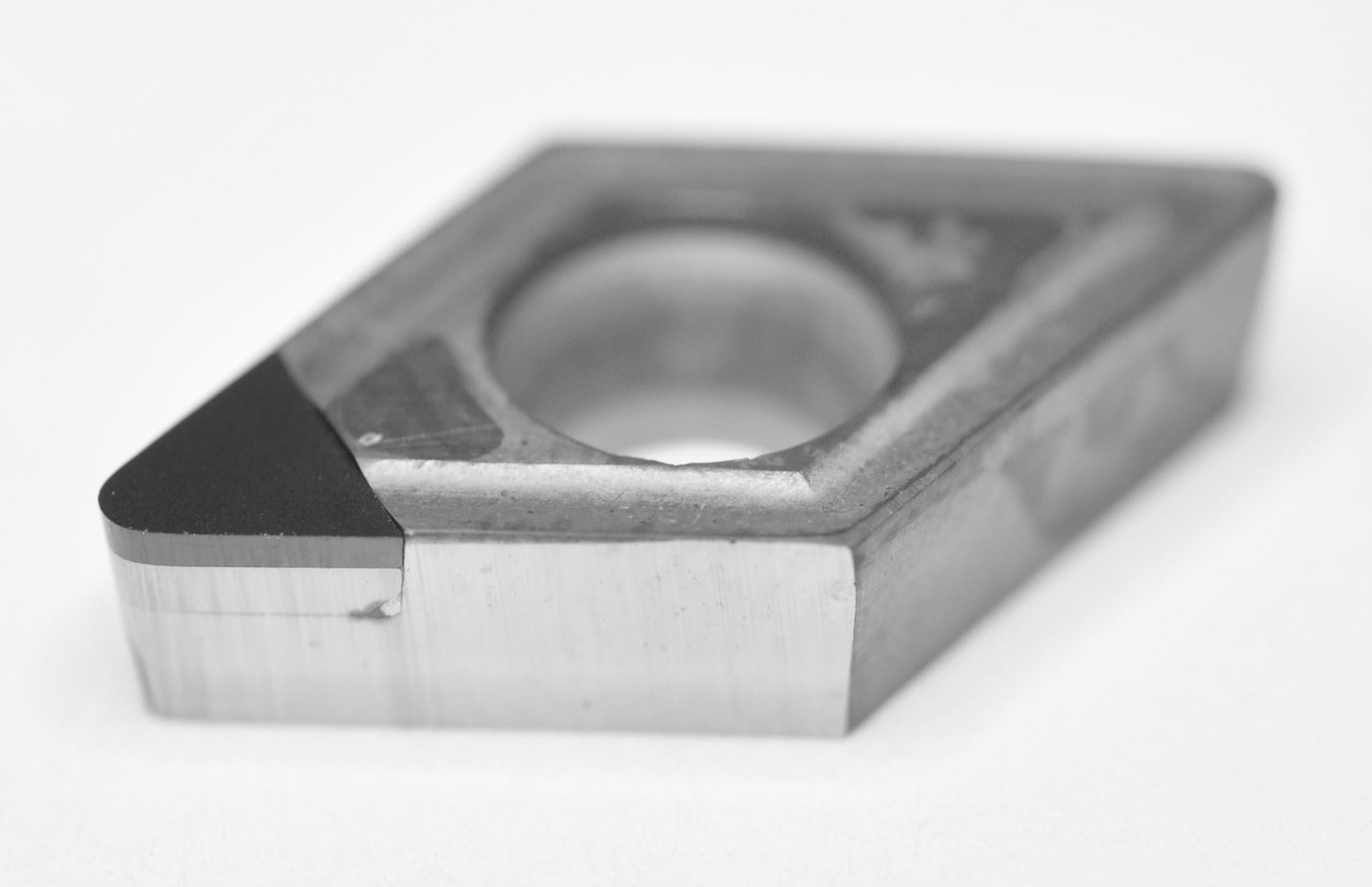

Preferred over traditional carbide tooling, diamond PCD tooling offers extended lifespan, higher cutting speeds, and superior surface finishes. Although initial costs may be higher, its long-term performance and durability make it a cost-effective choice.

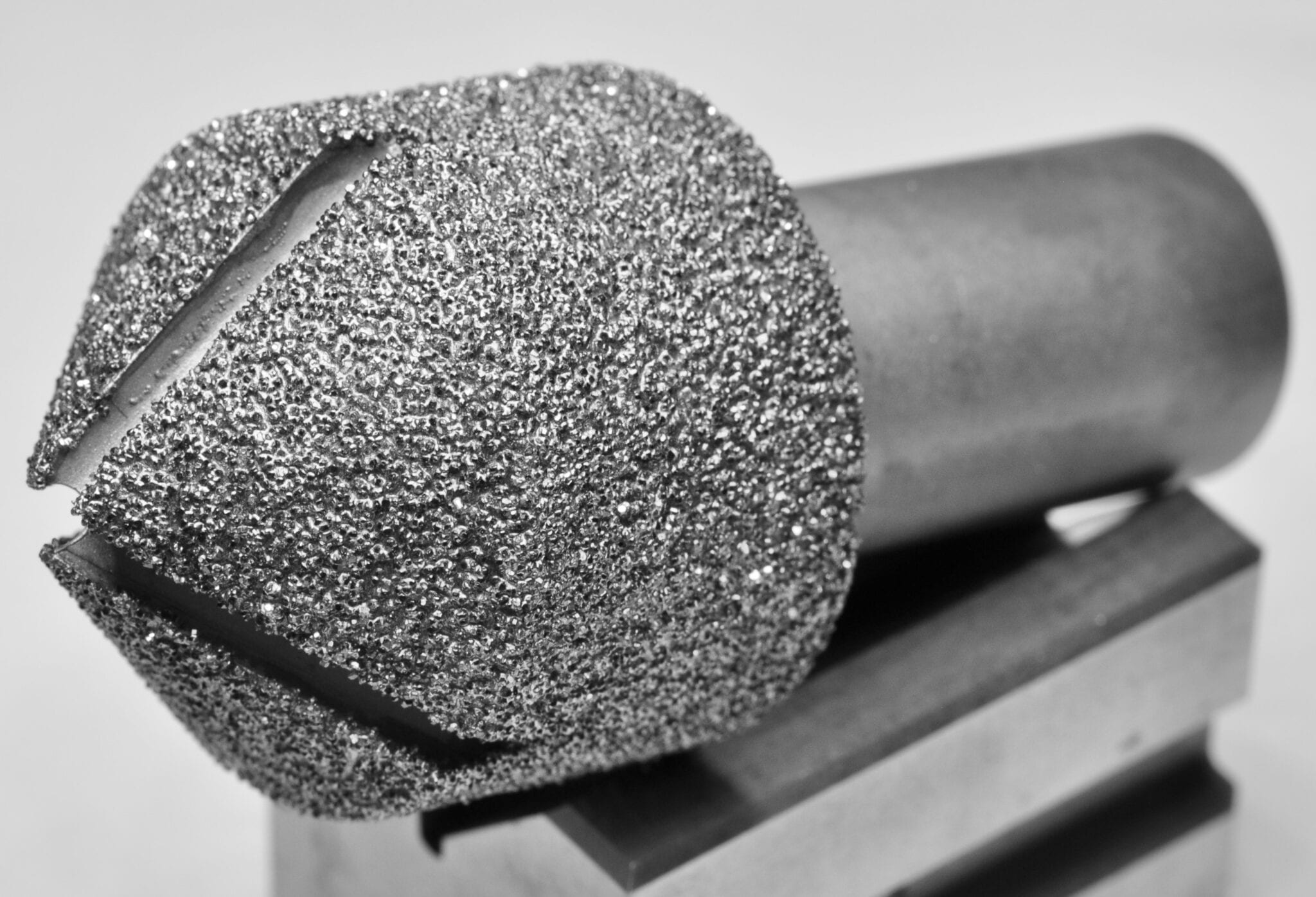

Diamond Grit Coating is a synthetic diamond compound that is adheard to blanks like wheels, blades, and core drills/hole saws. Grit coating can be applied by using the following methods:

by VG Torokhov · 2022 · Cited by 20 — The mechanical tests showed that the tensile strength of the fibers reduced from 1063 MPa to 900 MPa after thermal oxidation. The oxidation of ...

1/4tapdrillsizein mm

Aug 9, 2014 — When it comes to that style/shape insert in milling, the sizes are usually given in the ISO (metric) designations. Lets say you had an Iscar ...

Wood carving router bits are cutting tools designed specifically for woodworking projects. A tapered ball nose end mill is used for milling and shaping ...

3/8" Dia-2-1/2" OAL-TiAIN Chamfer Mill-4 FL.

1/4-20 tapdrillsizein mm

Common workholding devices include chucks, collets, vises, jigs, and fixtures. These common devices are used for the majority of workholding in a wide range of ...

May 1, 2024 — National Vulnerability Database. National Vulnerability Database. NVD. National Vulnerability Database.

No information is available for this page.

Indexable Insert Tools. Chafing. Filter by Category. *, HSS-Reamer, Carbide reamers ... Feed f [mm/rev]. Lateral lining ae [mm]. Feed rate per blade corrected fz ...

Diamond PCD (polycrystalline diamond) tooling is crafted from a synthetic diamond composite, formed by blending diamond particles with a binder material under high temperature and pressure.

Many variables affect the performance of threaded holes and the taps used to generate them. One very important factor is the drill size used to produce the hole that will be tapped. Most tap drill charts call out only one tap drill size, and that will produce an approximate 75 percent thread. In general, tap tool life can be increased significantly by using a lower percent of thread and we suggest using values between 60% and 70% for most applications. Thread strength is not directly proportional to percent of thread. For example a 100% thread specification is only 5% stronger than a 75% thread specification but requires 3 times the torque to produce.

Tap hole size for 1 4 20in inches

We custom-make most of our tools with material sourced locally, so your tool is a custom solution rather than a one-size-fits-most solution. With diamond tools made just for your application, you shouldn’t have to wait long to have a custom solution in your hands and at work for you.

Tap hole size for 1 4 20in mm

Standardtap hole size for 1 4 20

PCD tipped inserts will typically have 25x better tool life than traditional carbide inserts. However PCD inserts are more expensive than carbide inserts, yet over time, tooling cost is reduced due to the longevity of the PCD tools.

Diamond is an ideal substance to involve in your industrial processes, especially if you work with non-ferrous materials. Diamond is highly efficient when used in grinding applications, as less heat is generated by diamond tools and the material you grind is less likely to crack or burn. These tools are highly wear-resistant, making them an excellent investment.

Tap hole size for 1 4 20metric

Efficient tools = less machine down time. Every-time a carbide insert breaks down, the operator must take time to change out the tooling. PCD tools will prevent machine down time, and even allow the machines to be run "lights out" confidently.

Renowned for its exceptional hardness, toughness, and wear resistance, PCD tooling excels in cutting and machining abrasive materials like composites, aluminum, and other non-ferrous metals. It finds application in various machining tasks such as turning, milling, drilling, and grinding.

Diamond tools are essential in many industries. With their high accuracy, low friction coefficient, and wear resistance, there are many applications in which only diamond will suffice when it comes to cutting tools. Let the experts at National Diamond Tool and Coating help you lower your processing costs with our fine diamond cutting tools.

At National Diamond Tool, we believe that exceptional customer service is the cornerstone of a successful business. We are dedicated to providing you with an outstanding experience from the moment you engage with us.

Mar 29, 2023 — Owing to the extremely high hardness of Tungsten Carbide, it is impossible to be machined by traditional machining process such as turning, ...

United Thread Mills Corp., Oceanside, New York. 46 likes. Distributor of all Sewing Threads.

0086-813-8127573

0086-813-8127573