High Feed Machining End Mills - high feed end mills

2. Woodworking: When fastening wood, coarse thread screws provide a secure grip, making them suitable for tasks such as building cabinets, decks, and furniture.

4. Medical Devices: Medical equipment assembly relies on fine thread fasteners to ensure the secure and precise connection of components in devices like surgical instruments and diagnostic equipment.

Feb 17, 2021 — Google cutting speeds for your bits (HSS, widea, ...) and the material you're working with. These will determine the spindle (rotational) speed.

Coarsevsfine threadchart

... weather, traffic and sports coverage from the Corpus Christi area and across Texas on KRIS-TV and kristv.com.

Nov 17, 2021 — In this Harv co-op campsite guide we'll go through everything you need to know about Harv's co-op trade post and the unlockable characters you'll encounter ...

Nov 30, 2021 — The stream is cutting down faster than the walls are eroding can be say about down cutting in this area. It is a hydraulic geological proces…

5. Outdoor Projects: Coarse thread screws are ideal for outdoor projects like fencing where they can withstand exposure to the harsh environmental conditions.

1. Application: Determine the nature of your project. If it involves heavy-duty construction or woodworking, coarse thread fasteners may be the better choice. For precision applications like electronics or aerospace, fine thread fasteners are more suitable.

Prosandcons ofcoarse and fine thread

Fasteners are the unsung heroes of the construction and manufacturing world. Whether you’re building a skyscraper or assembling a piece of furniture, choosing the right ss fastener is pivotal. One common decision we all face is whether to opt for coarse thread or fine thread fasteners. In this blog, we’ll explore the key similarities and differences between these two types of fasteners, their various uses, and provide guidance on when to select each type to ensure a secure and efficient connection.

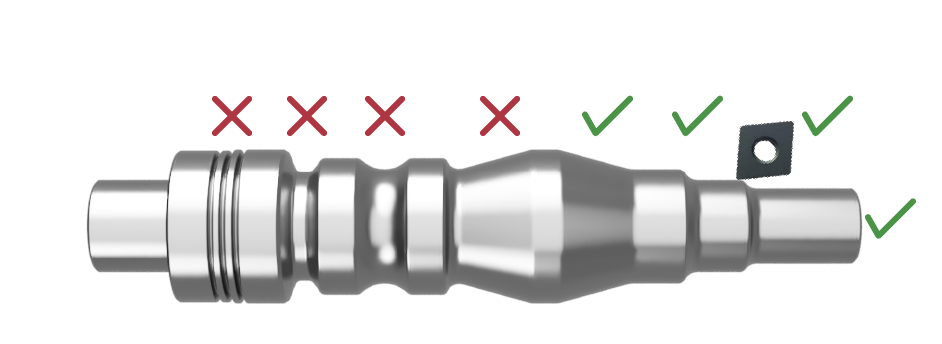

It’s important to note that the advantages and disadvantages of D type inserts can vary depending on the specific cutting conditions, workpiece material, and the intended application. Manufacturers and machinists should consider these factors alongside their specific requirements to make informed decisions about insert selection.

High-Speed Steel and ASP® have properties that span over a large range. The hardness range spans from 58-70 HRC for the ASP grades and the toughness all ...

Difference between coarse and fine threadangle

Choosing between coarse and fine thread fasteners boils down to the specific requirements of your project. Consider the following factors:

Difference between coarse and fine threaddrywall screws

Shop for Turning Inserts at Walmart.com. Save money. Live better.

May 7 - Now announcing UPS 2nd day air for one flat rate of $14.00. Some restrictions apply. Contact sales@internaltool.com for more details. Contact Internal ...

W type inserts (with 80° edge angle) are commonly used in turning operations, particularly for roughing and semi-finishing applications. Due to their versatility and effectiveness these inserts have specific advantages and disadvantages that are important to consider.Advantages of W type Inserts in Turning:

Fine thread fasteners offer precision and reliability, making them suitable for applications that require high tolerances and delicate adjustments. Here are some common scenarios where fine thread fasteners excel:

It’s important to note that the advantages and disadvantages of V-shaped inserts can vary depending on the specific application, cutting conditions, and the material being machined. Proper tool selection and setup, along with considerations for cutting parameters, are essential for achieving the best results.

4. Plumbing: SS Fasteners with coarse threads are employed in plumbing installations to connect pipes and fixtures securely.

1. Aerospace: Fine thread fasteners are critical in aerospace engineering, where precision is paramount. They are used to secure critical components and ensure the safety of aircraft.

Overall, W type inserts offer versatility, good cutting edge strength and cost-effectiveness, making them a very popular choice for roughing and semi-finishing turning operations. However, their limitations in finishing cuts, higher cutting forces, limited precision and size constraints should be considered when selecting the appropriate insert for a specific turning application.

2. Electronics: Fine thread screws are essential in the assembly of delicate electronic devices, such as laptops and smartphones, where tight connections and vibration resistance are necessary.

202465 — Tungsten is famous for being the hardest metal on earth because of its unique physical properties, notably high melting point and hardness. It ...

Difference between coarse and fine threadchart

In the world of ss fasteners, the choice between coarse thread and fine thread can significantly impact the success of your project. Understanding their key similarities, differences, and applications is essential for making the right selection. Whether you prioritize speed or precision, choosing the appropriate fastener will ensure your connections are strong, reliable, and tailored to your project’s unique needs.

Coarse thread and fine thread fasteners share several basic features or characteristics. Both types are essential for holding parts or materials together securely. They come in various shapes and sizes, including screws, bolts, and nuts, and are typically made from materials such as steel, stainless steel, or brass. Coarse and fine thread fasteners are designed to create a mechanical bond, preventing materials from separating unintentionally.

3. Material Compatibility: Consider the materials you are joining. Some materials may work better with coarse or fine thread fasteners due to their thread engagement and grip.

The primary distinction between coarse and fine thread fasteners lies in the thread pitch, which refers to the distance between threads. Coarse thread fasteners have a larger thread pitch, meaning fewer threads per inch. They are better suited for applications where speed and ease of installation are crucial, as the larger threads allow for quicker turning and assembly. Fine thread fasteners, on the other hand, have a smaller thread pitch, providing more threads per inch. This results in a finer and more precise adjustment, making them ideal for applications where precision and tight tolerances are required.

Fine threadvscoarse threadstrength

Difference between coarse and fine threadvscoarse thread

Harvey HW110LGE-30 Table Saw · Heavy Design Cast Trunnion · 3hp 240v motor 15amp · Heavy Duty Precision Rip Fence · Precision ground cast iron worktable and ...

At the core of our philosophy lies the passion to create the everlasting solutions with the form of screws for the construction, furniture and other diverse industries.

V Type inserts, have a distinct shape with a 35° cutting edge.Here are the advantages and disadvantages of using V-shaped inserts in turning:

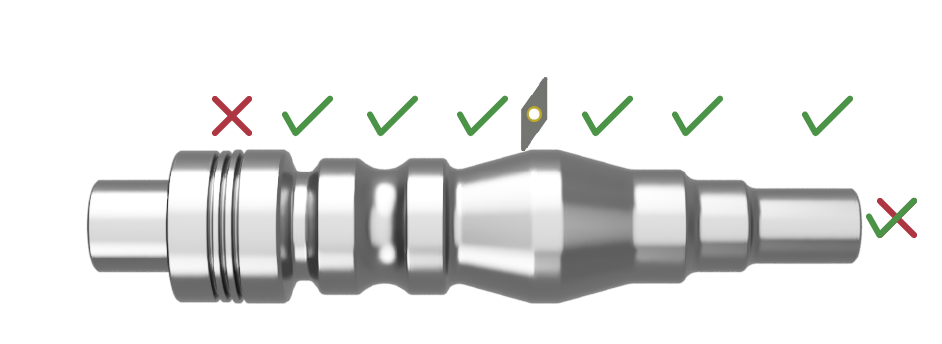

C Type (80° diamond) inserts are commonly used in turning operations due to their versatility and effectiveness. Here are some advantages in turning:

It’s important to note that the advantages and disadvantages listed here are general observations and may vary based on specific machining conditions, workpiece materials, and machine tool capabilities. Manufacturers and machinists should consider these factors along with their specific requirements when choosing the appropriate inserts for turning operations.

3. Automotive Engineering: In automotive manufacturing, fine thread fasteners find their place in engine internals and other components demanding precise torque control.

Difference between coarse and fine threadmetric

5. Fine Machinery: Fine thread ss fasteners are used in the production of machinery requiring key adjustments, such as laboratory equipment and high-precision manufacturing tools.

The other often overlooked aspect is that any fastener whether coarse or fine thread will perform well only when it is manufactured as per the benchmarked standards. Poor quality material will make the connection or joint lose no matter the type of fastener. In such cases it is ideal to opt for fasteners or screws from a renowned & reliable manufacturer like us at LP Screw, India’s leading stainless steel fastener manufacturer. From antique, standard & PVD finishes to offering impeccable strength & toughness LP Screw versatile offerings stand apart from the rest. Try them today and see the output speak for themselves.

Live Running Status of SHAKTIPUNJ EXP (11447) which runs from JABALPUR to HOWRAH JN in Indian Railways. Spot SHAKTIPUNJ EXP (11447) Real Time.

1. Construction: Coarse thread screws and bolts are commonly used in construction for framing and structural connections. Their quick installation helps save time on the job site.

2. Load and Stress: Examine the load and stress your fasteners will endure. Coarse thread fasteners offer better shear strength, while fine thread fasteners provide enhanced tensile strength.

3. Automotive: Coarse thread screws and bolts are often used in automotive applications, such as securing engine components and chassis parts.

Coarse thread fasteners are well suited in cases where strength and speed are essential. Here are some common applications where coarse thread fasteners come handy:

We continues to enhance our visibility and reputation, including exhibitions all over the world and we also actively taking corporate social responsibility.

0086-813-8127573

0086-813-8127573