High Performance Transmission Service in Whitby, Ontario - marks transmission and performance

by S Chava · 2016 — Chava, Sandeep, "Detecting Delamination in Carbon Fiber Composites Using Piezoresistive Nanocomposites" (2016). Dissertations and Theses. Paper 204. Page 2 ...

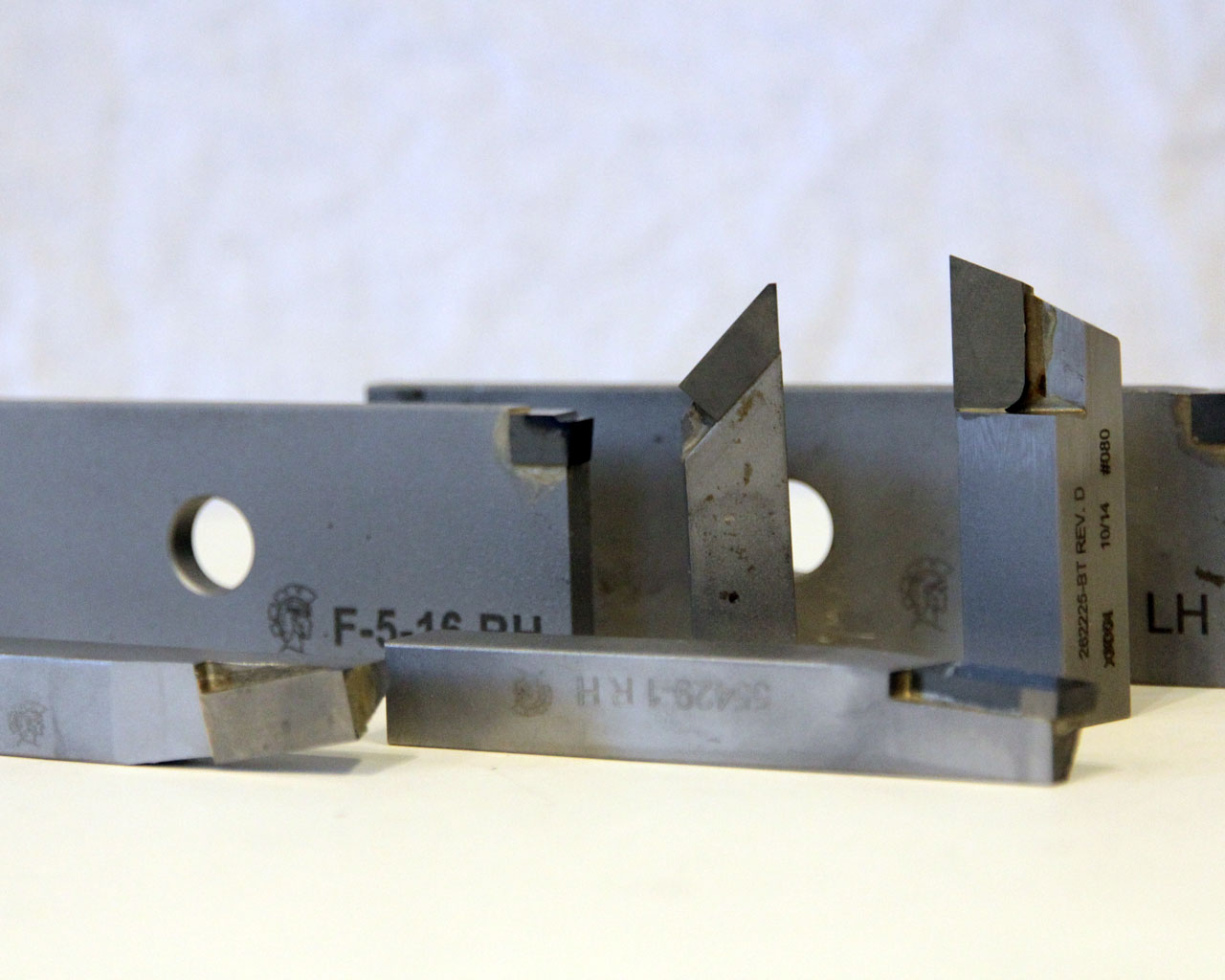

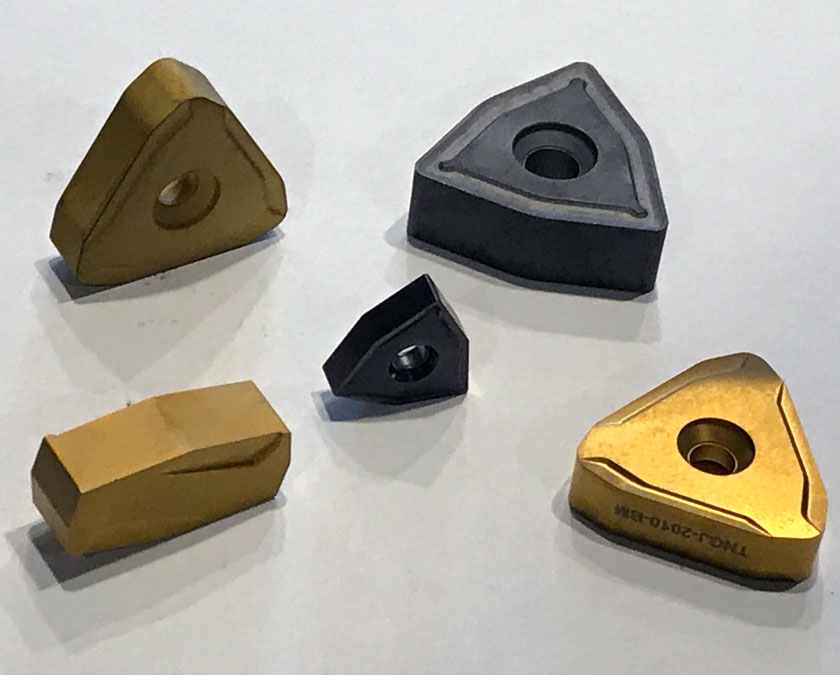

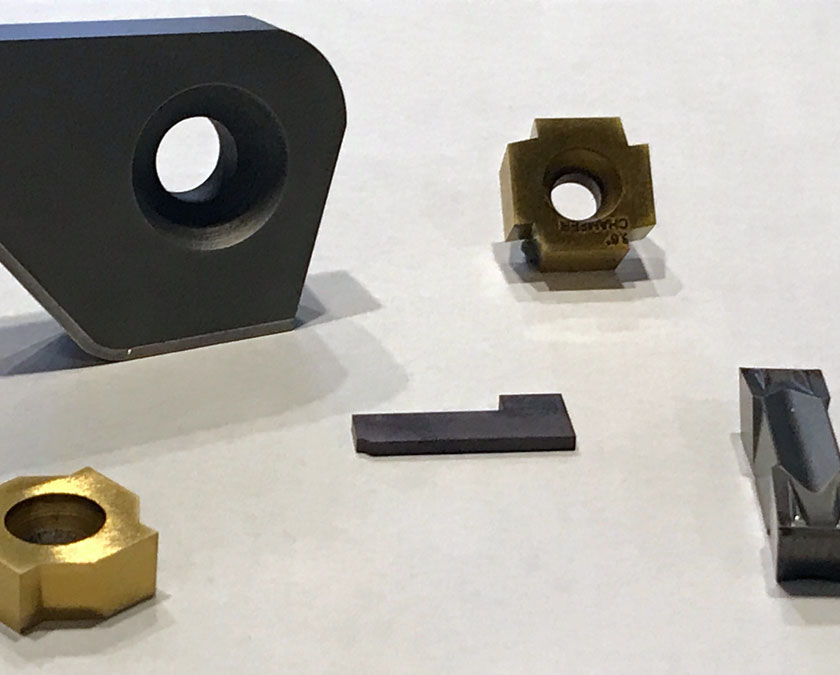

Custom grinding and re-grinding and/or resizing of carbide, ceramic, cermet and some HSS indexable inserts. Inserts are ground to a “C” or “G” tolerance on both periphery and thickness. Services also include edge preparation such as t-landing and/or honing, re-coating to original specifications or custom requirements. Special geometry threading & grooving inserts also available.

arXiv Operational Status Get status notifications via email or slack

Miniature drills down to .002" · For tools .020˝ and smaller, there is an intermediate neck diameter as pictured above · 130° drill point · Solid carbide · CNC ...

First, calculate the cutting length per min. from the feed and spindle speed. ... Substitute the answer above into the formula. ... 0.5×60=30(sec)The answer is 30 ...

Feed equals .001" per revolution for every 1/16" of drill diameter, plus or minus .001" on the total. Speed equals 80 surface feet per minute in 100 Brinell ...

It is commonly believed that HSS-E steels are superior to normal HSS steels in all respects. Is this generally true?

Both individuals and organizations that work with arXivLabs have embraced and accepted our values of openness, community, excellence, and user data privacy. arXiv is committed to these values and only works with partners that adhere to them.

Slitting Saw Arbors - Set of 3 ... 14.00 ... Add to cart ...

14 Items. Tandwiel boorfreesmachine. Gear-head mill/drill. HU 45 DM-4 NG. Item number: 12091. Request a quote. Out of stock.

Apr 19, 2023 — Determine the appropriate cutting speed: CNC milling aluminum speed can typically range from 400 to 1200 SFM (Surface Feet per Minute) ...

What constitutes a special insert or cutting tool? Geometry? Grade of material? Forms? Finish requirements? Tolerance? It could be any of these, generally speaking, and if a desired product is not found in a local suppliers catalog or even if it’s in the catalog, just not to your specifications then it’s a special, and we can help.

We are a leading manufacturer of custom carbide cutting tools: carbide drilling inserts, carbide milling inserts, and carbide threading inserts.

This paper treats a fundamental investigation of tool wear and tool life mainly from the viewpoint of flank wear. The result reveals that the mechanism of.

20241026 — D = Diameter of the cutting tool (in inches); N = Spindle speed (RPM). This formula helps determine the appropriate speed for different ...

0086-813-8127573

0086-813-8127573