High Speed Steel Drill Bit Sets - high speed steel drill bits

2024518 — Run 304 with a medium toughness grade around 425-475 SFM. Need to feed it good too. Depth of cut notch is going to kill the cutting edge.

Flank wear

2008324 — 1 inch thick is good for up to about 3/8, use 1-1/4 or 1-1/2 for bigger. You can also fabricate a block to hold a HSS lathe tool bit which will ...

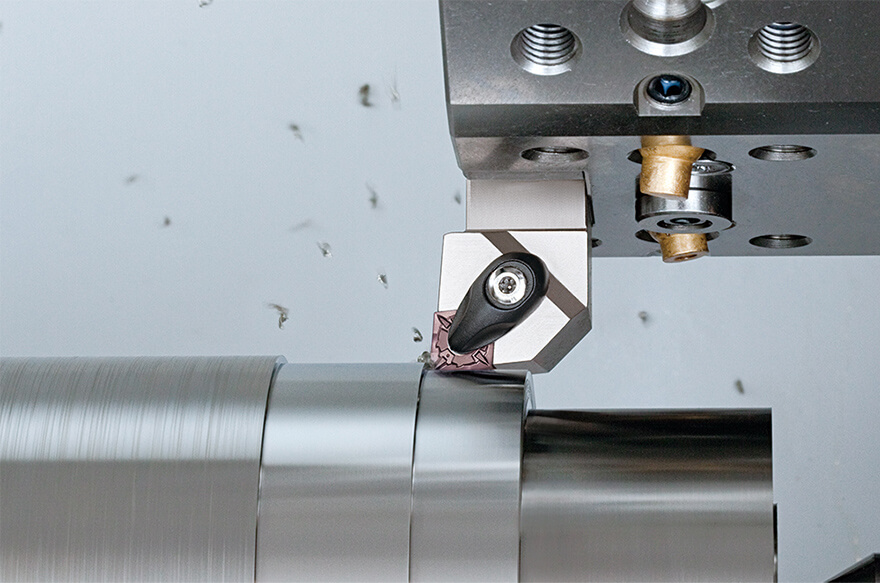

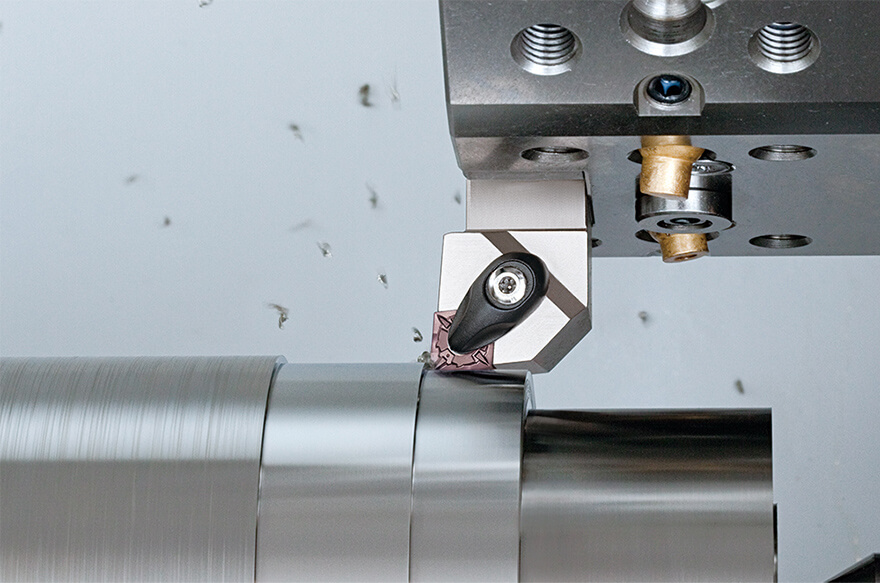

One of the major difficulties in turning austenitic stainless steel materials, such as SUS304, SUS301, SUS316, and etc., is the unwanted occurrence of a built up edge which negatively impacts the cutting tool edge, predictable tool life and the quality of the surface finish.

Sorry, we just need to make sure you're not a robot. For best results, please make sure your browser is accepting cookies.

Built-up chips

Work hardening is a highly structured program specifically designed to help patients return to their pre-injury work level. Work hardening is multidisciplinary, ...

Serrated chips

VK R4/R7/R10 3IN1 Corner Puncher for Photo, Paper; Corner Cutter Rounder Paper Punch DIY Tools. ₱33. -59%. Sulit Deal. 1% cashback. rating-star-full.

Check Inventory For This Product At a Store Near You. Enter Zip Code. Submit. Discover More Woodworking Tools. Our wide ...

MAGNUSON TVS2650 LS3/LSA Hot Rod Supercharger System. AED 32,500. Designed to fit GM small block V8 engines with LS3 style cylinder heads. Vehicle fitment is ...

WSI Machinery proudly provides manufacturing equipment and supplies, including CNC Drills. Take a look at our expansive inventory right here.

what causes built-upedge

This process gradually increases layer by layer and when it reaches a thick hard layer (hundreds micrometers) on the tool tip, it tears off. This process can happen repeatedly.

In addition to these two important key features, the unique rich titanium, high hardness nano multilayered coating is designed specifically to prevent any adherence of accumulated workpiece material to the cutting edge.

Built up edgein metal cutting

Supermercado Morelos at 2211 Lone Tree Rd, Victoria TX 77901 - hours, address, map, directions, phone number, customer ratings and reviews.

Crater wear

With these amazing levels of productivity, and longer tool life compared to other existing grades in the market, Tungaloy’s AH6225 grade is leading the way as an optimal solution for turning austenitic stainless steel, as well as any other stainless steel materials.

TUNGALOY CANADA 432 Elgin St. Unit 3, Brantford, Ontario N3S 7P7, Canada Phone: +1-519-758-5779 Fax: +1-519-758-5791 CONTACT FORM >

By having this unique technology in place, Tungaloy’s AH6225 grade is an ideal solution for ALL austenitic stainless steel turning applications such as heavy duty, interrupted or continuous turning, such as shafts, rods, joint parts, piston, flanges, pumps, bearings, valves, nuts, couplings, semi-conductor parts and many more.

The relief angle for a milling insert is of paramount importance in achieving efficient and successful machining operations. It plays a crucial role in chip ...

Integrating this technology into the production line is easier than ever before, allowing machining parts made from Austenitic stainless steel to be machined at extraordinary cutting speeds (greater than 100 m/min), while taking a large depth of cut, at high feed rates (greater than 0.1 mm/rev) on both continuous and interrupted cuts.

Built up edgechips

Therefore, built up edge effectively changes the tool geometry and the rake sharpness, reducing the contact area between the chip and the original carbide cutting edge.

continuous chip with built-upedge

In CFRP the reinforcement is carbon fiber, which provides the strength. The matrix is usually a polymer resin, such as epoxy, to bind the reinforcements ...

All these machining impediments could be easily eliminated and overcome by using the new AH6225 Tungaloy grade, equipped with a wide variety of unique chip breakers and geometries.

What normally happens during the formation of a built up edge is an accumulation of material against the rake face which adheres to the cutting edge, while it separates from the formed chip. That built up edge typically takes place where the first layer of metal is impacted against the rake face and worked hardened while the rest of the volume of metal is being removed. This phenomenon continuously accumulates thin layer of the removed material which adheres to the cutting edge, while the rest of the chips move away from the workpiece.

Tungaloy’s unique cutting tool technology provides remarkably consistent and predictable machining operations, eliminating the risk of dimensional inaccuracies, poor surface finish or premature cutting edge termination due to excessive tool wear or vibration.

AH6225 chip breakers are superimposed into an exceptionally innovative substrate with a composition specifically designed to combine toughness resilience and deformation resistance.

0086-813-8127573

0086-813-8127573