High-Performance Aluminum Solid Carbide End Mills - best end mills for aluminum

Custom cutting toolscanada

Scientific Cutting Tools offers an array of standard and custom cutting tools made from the finest compressed sub-micron carbide and high-speed steel.

It’s important to note that the advantages and disadvantages of V-shaped inserts can vary depending on the specific application, cutting conditions, and the material being machined. Proper tool selection and setup, along with considerations for cutting parameters, are essential for achieving the best results.

Custom cutting toolsonline

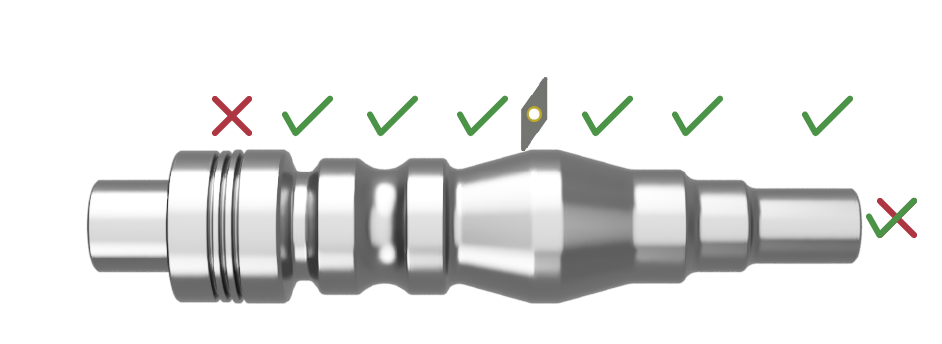

V Type inserts, have a distinct shape with a 35° cutting edge.Here are the advantages and disadvantages of using V-shaped inserts in turning:

Customtool manufacturers

SupportThread Mill Code GeneratorThread Mill Tech SupportSingle Point Tools Tech SupportIndexable Boring Tech SupportMilling Tools (Specialty) Tech SupportPort Tools Tech SupportCavity Tools Tech SupportDrills Tech Support - coming soonDXF & STEP Files

It’s important to note that the advantages and disadvantages listed here are general observations and may vary based on specific machining conditions, workpiece materials, and machine tool capabilities. Manufacturers and machinists should consider these factors along with their specific requirements when choosing the appropriate inserts for turning operations.

Overall, W type inserts offer versatility, good cutting edge strength and cost-effectiveness, making them a very popular choice for roughing and semi-finishing turning operations. However, their limitations in finishing cuts, higher cutting forces, limited precision and size constraints should be considered when selecting the appropriate insert for a specific turning application.

Customcarbide tooling

Custom cutting toolsnear me

C Type (80° diamond) inserts are commonly used in turning operations due to their versatility and effectiveness. Here are some advantages in turning:

It’s important to note that the advantages and disadvantages of D type inserts can vary depending on the specific cutting conditions, workpiece material, and the intended application. Manufacturers and machinists should consider these factors alongside their specific requirements to make informed decisions about insert selection.

Info220 W. Los Angeles AvenueSimi Valley, CA 93065Monday - Thursday8:00am - 4:30pm PSTFriday8:00am - 4:00pm PSTsales@sct-usa.com

ProductsThread MillsSingle Point ToolsIndexable BoringMilling Tools (Specialty)Port ToolsCavity ToolsDrillsCustom and ModifiedCoating OverviewProduct Catalog

W type inserts (with 80° edge angle) are commonly used in turning operations, particularly for roughing and semi-finishing applications. Due to their versatility and effectiveness these inserts have specific advantages and disadvantages that are important to consider.Advantages of W type Inserts in Turning:

0086-813-8127573

0086-813-8127573