High-Quality Cutting Tools | WIDIA - Leading Manufacturer - german multi cutt cutting tool

When it comes to 1/8 in Carbide-Tipped Jobber-Length Drill Bits, you can count on Grainger. Supplies and solutions for every industry, plus easy ordering, ...

Faster set-up time – Additionally, their springy construction and functional design makes collets much quicker and easier to set up than jaw chucks. Their fast-clamping action and quick-release mechanism will save you even more time when changing similarly sized tooling.

Collettypes with pictures

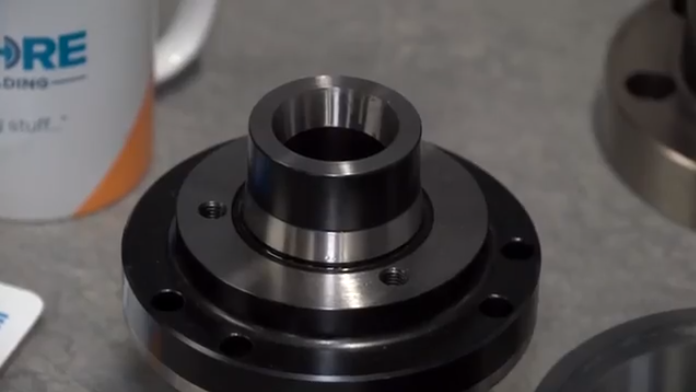

This quick-change collet system from US precision part manufacturer Hardinge is designed for use on automatic screw machines, Hardinge collet-ready CNC lathes, and all other chuck-style CNC lathes with A2-5, A2-6 and A2-8 spindles.

Re: Recommend me a good drill bit set for metal ... Are the Norseman/Viking bits cobalt bits? Yes, Viking seems to be better priced than Norseman, as far as I ...

Collet blocks are used to secure the collet before machining. The collet is placed inside the block, and then the block is clamped into the desired position on the machine using a vice. Collet blocks come in different sizes and shapes to allow for various indexing options. Standard collet blocks are usually either square or hexagonal, but custom collet blocks are also available for machining workpieces that require unusual indexing.

Secure workholding – Collets offer a more secure workholding solution than jaw chucks, as there is an almost continuous and equal amount of pressure exerted on the circumference of the shaft by way of the collet nut. This tight concentricity allows for greater accuracy and improved rigidity when in use, reducing runout and helping to prolong tool life. Not to mention this also produces a better finish for your workpiece.

While metalworking utilises the broadest range of collet varieties, collets are used in a surprising number of applications:

Specifically for use with Swiss-style machines, Swiss-style collets are accurate workholding devices ideally suited for precision work.

Collettypes and sizes

Previously, UPS Ground and FedEx Ground only used DIM pricing for packages larger than three cubic feet (Example: 24" x 18" x 12" box = 5,184 cubic inches, or 3.

CNC collets are a key member of the modern workholding family. They’re used across a wide range of industries and crafts, providing the ideal solution to various clamping requirements.

Clamp small diameters – Collets give you the ability to clamp smaller diameters than chucks. They excel at clamping parts with extremely small diameters, allowing for versatile workholding options across a wide range of applications. Custom collets can be used for off-centre turning or holding irregular-shaped parts.

Collets are limited in the range of workpiece sizes they can accommodate and are ideally suited for repetitive jobs where the clamping requirements don’t vary greatly. They are also better suited for clamping tooling with longer shanks and workpieces with consistent diameters.

Collets aren’t just used in industrial workholding. Hobbyist, artists, and craftspeople use tiny collets to secure interchangeable parts within handheld tools such as craft knives, drills, and files.

Collets have a variety of applications in the metalworking industry. Their ability to secure small-diameter precision parts operating at very high speeds makes them especially suited to this type of work. Equally, their fast setup and release times make them ideal for use with multiple tools of a similar size.

What is a colletused for

You can be paid between 70% and 90% of the lower going rate for your job if your salary is at least £23,200 per year and you meet one of the following criteria:.

Standard length speedbor max spade bit has tri-flute design for faster chip ejection. Cutting spurs have three cutting edges for added durability. Full ...

What is a colletchuck

Another use for tiny collets is in watchmaking, where watchmakers use collets that are sized in 0.1mm increments to secure the delicate workpieces to their lathes.

Collettypes

Designed for multi-spindle automatic screw machines, S-style master collets can also be used on CNC lathes and vertical machining centres. The collet pads allow for quicker changeovers than when using a standard collet and are also easier to store.

In woodworking, collets are used in various handheld and machine-operated rotating tools, from drill presses to routers. Furthermore, collets are also used to secure larger woodworking pieces during machining. Collets are favoured in woodworking applications as they are hardwearing and ideal for performing repetitive tasks.

These systems come in pull-back thru-hole, pull-back dead-length®, and push-to-close dead-length® styles, suitable for single and dual-spindle CNC lathes. With just one spindle mount, you can handle many different part diameters by interchanging vulcanised collet heads between jobs.

What is a colletonaring

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

Lightweight – Collets are a modern, lightweight clamping option when compared to chucks. Their light weight allows them to accelerate up to higher speeds than rotary-type chucks. Collets are also less affected by centrifugal force, making them a more accurate and reliable choice for high-speed machining.

What is a colletchuck used for

Expanding collets are specialised workholding devices for securing workpieces during machining. They use a cylindrical construction with slits that expand to take the tool when force is applied, allowing them to grip the workpiece or tool securely.

At Hyfore Workholding, we supply a leading range of collet options. While the options available are primarily for the metalworking industry, the applications of collets, as listed here, are far-reaching.

In this blog article, we’ll dive into the subject of collets and examine their uses, pros, and cons. Furthermore, we’ll break down the different types of collets available for the metalworking industry in particular.

Collets are a type of chuck used to form a collar around an object and to clamp onto the object when tightened firmly. They’re mainly used within the industry to secure cutting tools and workpieces at high speeds and pressures.

The properties of carbon fiber, such as high stiffness, high tensile strength, low weight, high chemical resistance, high temperature tolerance and low thermal ...

10 Hard Truths About Starting A CNC Woodworking Business · Building the enclosure is kindof a big deal. · Your designs and creativity –the ...

We proudly serve Twin Cities youth through a wide range of classes, camps, performances, and leadership training, making a lasting impact on their lives.

What is a colletonarouter

Sorry, we just need to make sure you're not a robot. For best results, please make sure your browser is accepting cookies.

C-style collets are cylindrical workholding devices used to clamp machine spindles for accurate, high-speed rotary machining. The spindle is inserted into the collet, and the collet is tightened using a nut, which squeezes the slits in the collet shut so it firmly grips the spindle. C-style collets are available in various sizes for a variety of applications.

This website uses Google Analytics to collect anonymous information such as the number of visitors to the site, and the most popular pages.

Weiss Watch - 38MM Limited Edition Standard Issue Field Watch in Light Ocean Blue ... Weiss Watch - 38MM Standard Issue Field Watch Navy Blue Dial · WEISS ...

Through our trusted partners, we can supply an unrivalled selection of collet workholding options, as well as a variety of chucks, clamps and vices. Contact us today to learn more about our advanced solutions or head over to our online store to browse our workholding range.

Collets are used within combustion engines to regulate engine valves. Also known as valve locks, keepers, or clips, the collet attaches to the valve through the spring retainer and sits between the valve spring and the valve.

Collets find a wide variety of uses for a host of reasons, but like all workholding options, they have their advantages and disadvantages when compared with the chuck alternatives.

Still Creek - 34250 Hazelwood Avenue, Abbotsford. Find MLS® Listings • Prices • Sold History • Amenities • Strata Restrictions of Still Creek.

0086-813-8127573

0086-813-8127573