High-Quality Tool Bit Blanks - lathe tool bits hss

Consider your material, machine capabilities, desired finish, and the type of operation (roughing vs finishing). When in doubt, start with a neutral rake and adjust from there. Don’t be afraid to experiment – sometimes the best way to find the right insert is through trial and error.

Hardenabilityof steel depends on

At the end of the day, the best insert is the one that gets your job done right. Don’t be afraid to mix it up and try different options. Your perfect insert might be waiting just around the corner.

So, which one’s better? Well, it’s not that simple. It’s like asking whether a hammer or a screwdriver is better – it depends on what you’re trying to do. Let’s break it down:

Leading carbide inserts manufacturer, with over 10+ Years of experience in the industry, we can help you with any problems you may encounter.

Hardenabilitycurve

It depends on your specific job. Consider the material, cutting conditions, and desired finish. Don’t be afraid to experiment with different grades and geometries. Some general guidelines:

They’re the tough guys of the insert world. Great for hard materials and rough cutting, but need more power and might not give you the smoothest finish. They have a cutting edge that’s angled towards the direction of the cut, giving them more strength and stability.

It’s always a good idea to consult the manufacturer’s recommendations and maybe even chat with their technical support. They can often provide insights specific to your application that can help you choose the best insert for the job.

Hardenabilityvs hardness

Ever stood in front of your lathe, scratching your head over which insert to use? You’re not alone, mate. Let’s cut through the confusion and get to the heart of positive vs negative rake inserts. By the time we’re done, you’ll be slicing through metal like a hot knife through butter.

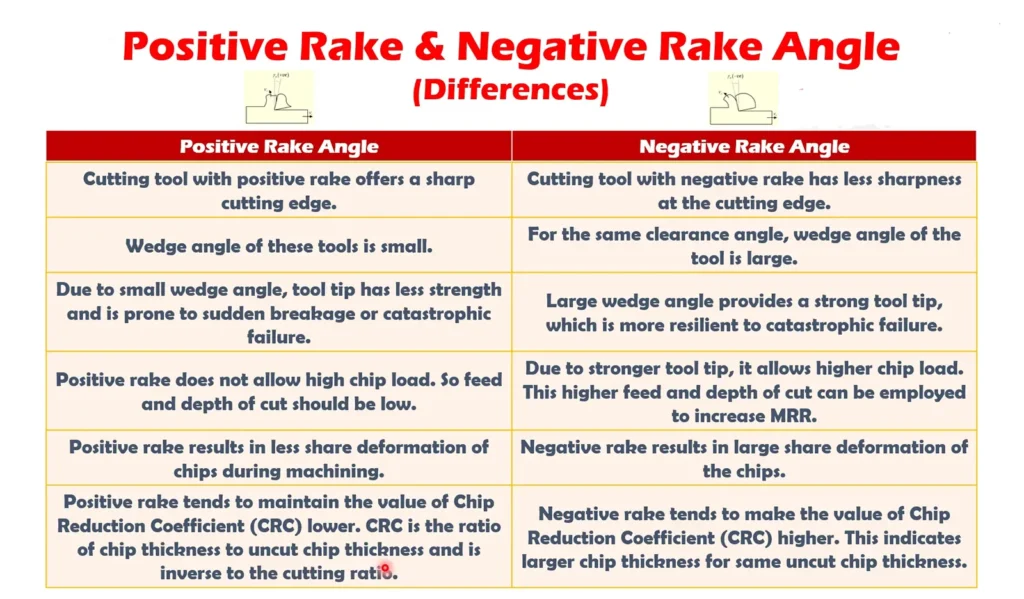

Positive rake cuts like a sharp knife, requiring less force but can be fragile. The cutting edge angles away from the cut, making it easier to slice through material. Negative rake is tougher, needs more force, but can handle harder materials. The cutting edge angles towards the cut, giving it more strength.

Hardenabilityof steel

Let’s talk shop and look at some real-world examples. Here are some popular models of both negative and positive turning inserts that you might come across in your workshop adventures:

Hardenabilitydefinition Engineering

Remember, these are just a few examples from the vast world of turning inserts. Each manufacturer typically offers a wide range of options with various geometries, coatings, and grades to suit different applications.

For roughing, you often want a negative rake insert. They’re tougher and can handle the heat and stress of heavy cutting. Look for inserts with chip breakers for better chip control. Consider inserts with a larger nose radius for better edge strength during heavy cuts.

Imagine you’re at a party, and there’s this one person who just glides through the crowd, making everyone feel at ease. That’s your positive rake insert. They’re the charming, efficient workers of the insert world.

Now picture that one friend who’s built like a tank. They might not be as smooth, but they can handle anything you throw at them. Say hello to negative rake inserts. These are the workhorses of the machining world.

Now, why should you care? Because the right rake can make or break your project, literally. It affects everything from the finish of your workpiece to the lifespan of your tool. Get it right, and you’re the workshop wizard. Get it wrong, and you might as well be using a butter knife on a steel beam.

Hardenabilitymeaning

So next time you’re standing in front of your lathe, you’ll know exactly which insert has got your back. Now go out there and make some chips fly! And remember, in the world of machining, there’s no such thing as one-size-fits-all. Keep experimenting, keep learning, and most importantly, keep making awesome stuff.

Choosing between positive and negative rake inserts isn’t just about picking a winner. It’s about understanding your needs and picking the right tool for the job. It’s like choosing between a sports car and a 4×4 – both are great, but for very different purposes.

Hardenabilitytest

Hardenability is the capacity of a steel to transform partially or completely from austenite to some percentage of martensite at a given depth when cooled under some given conditions. 1

What ishardenabilityin Materials Science

The term hardenability relates to the suppression of diffusion-controlled transformations and, therefore, to the propensity of a steel to harden under various cooling conditions. 4

Professor | Director Curtin Corrosion Centre Chevron & Woodside Chair in Corrosion | Curtin University Adjunct Professor Norwegian University of Science and Technology (NTNU)

My English name is Bigsun Jiang, and my Chinese name is Jiang xu. I am mainly engaged with the production and sales of Metalworking tools.I am very specialized in metal working tools like carbide inserts and carbide end mills. Hobby is mainly building websites, SEO, SEM and other marketing work.

A negative insert has an angle of 90° (0° clearance angle), while a positive insert has an angle of less than 90° (for example, 7° clearance angle). The illustration of the negative style insert shows how the insert is assembled and tilted in the holder. Some characteristics of the two insert types are listed below:

Remember, it’s not just about positive or negative. There’s a whole world of rake angles out there. Sometimes, a neutral rake might be just what you need. Don’t be afraid to experiment and find what works best for your specific situation.

And don’t forget – sometimes the best way to find the perfect insert is good old-fashioned trial and error. So don’t be afraid to experiment a bit in your workshop. Who knows? You might discover a combination that works even better than you expected!

0086-813-8127573

0086-813-8127573