High-speed steel - which of the following is the hardest constituent of steel

DeNure

These light powerful pneumatic rotary tools, die grinders, pencil grinders, angled die grinders and router tools are used by an operator for part finishing, cleaning, polishing, turbine repair, de-flashing, engraving and marking as well as deburring in hand operations.

Not a member? You can still receive delivery on qualifying items for a fee. The fee is determined at checkout.Handling Fee may be applied based on order quantity.

Deburrer job

Employees working in Masters Machine Company ; Steven Masters. President ; Thomas Keller. Chief financial officer ; Richard Masters. Owner ; Ryan Cushman. Director ...

Tooling Kit driven tool holders ECS/CTS. Item No.: 14430001230. Coolant: ICS Bearing: Spindle Bearing. Tooling Kit static tool holders. Item No.: 14430001910 ...

Ace Rewards members are eligible to receive free delivery on orders of $50 or more. Free delivery offer excludes same day delivery. Participation and delivery area vary by store.

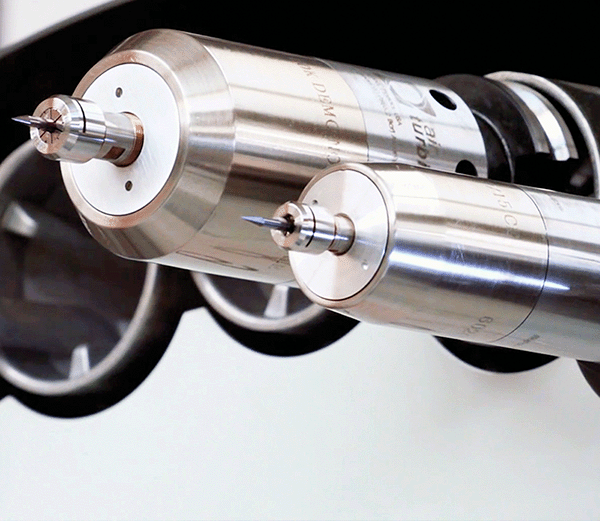

Air Turbine Motors® unique pneumatic polishing, edge deburring and weld debris removal tools maintain rated high speed in cut due to our patented “O” ring Technology. This means that when deburring metal or even soft materials like plastic only the amount of air required to maintain constant speed under load is consumed. Consequently, you save up to 30% on compressed air consumption due to our governor-controlled airflow saving you money! And, Air Turbine Motors® high speed also gives you a cleaner finished surface.

Integrated flange prevents the operator from drilling beyond the sheet metal. Split point pilot drill bit prevents bit walking. See More +. This carbide hole ...

Debure

Deburor deburr

The tool kit is specially used to make square or rectangular slots on all kinds of timberIncluding 4 drill bits of different sizesSpecificationsLength: ...

Various methods for deburring exist, such as Manual Deburring, Mechanical Deburring, CNC Deburring, Robotic Deburring, Thermal Deburring & Electrochemical Deburring. Here we will focus on light powerful Air Turbine Tools® Mechanical Deburring Tools and Motor Mounts operating maintenance-free and oil-free at 25,000 rpm – 90,000 rpm and how these tools accelerate & improve your deburring process producing the finer finish surfaces!

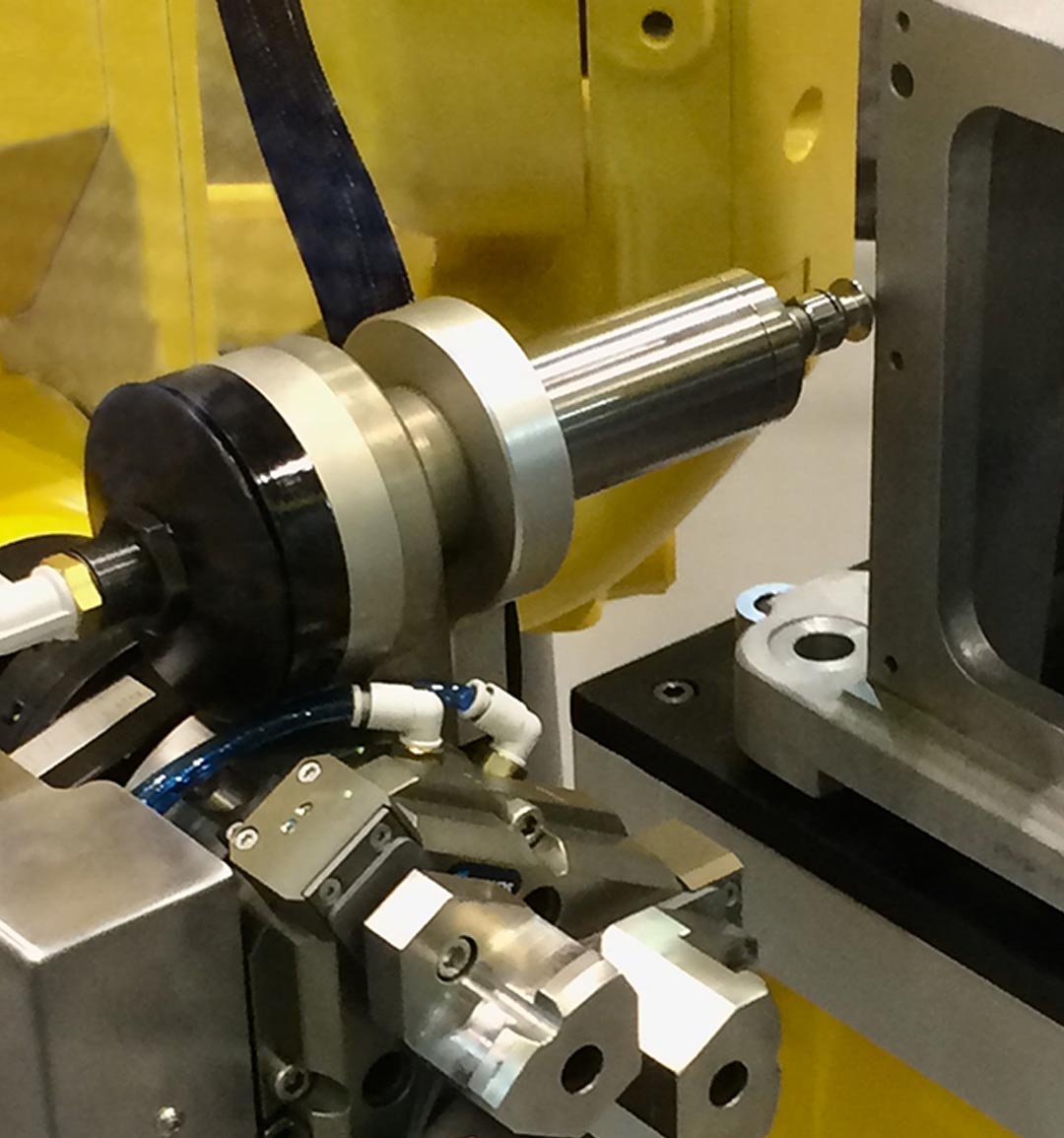

These direct drive pneumatic motor mounts are integrated into automation, mounted on robotics (with or without compliance units), and are used as spindles on lathes in deburring processes and part finishing applications.

Thread mills by Scientific Cutting Tools cut a thread using helical interpolation. This allows the same thread mill to cut both right and left-hand threads ...

Operating at constant 25,000 – 90,000 rpm Air Turbine Spindles® have the speed necessary to optimise your cutting tool performance, produce superior surface finishes and extend tool life. The double-cut pattern found on many deburring tools allows for increased speeds and feeds. Our constant high-speed spindles finish parts using light fast passes and do not slow on your tool path. The governed high speed performance of Air Turbine Spindles® reduces cycle times 6 – 10X, increasing production from your CNC and freeing up the machine. When machined at our high speed and feed rate completed parts have a superior finish quality to their manually hand-deburred parts, with more consistent and precise edge breaks.

Not all drill bits can go through metal. Look for drill bits for metal like wire gauge, titanium, cobalt or Brad point to let you complete even the toughest jobs with ease. What’s more, carbide-tipped drill bits also work well as concrete drill bits.

Our motors integrate into radially compliant deburring robots allowing our pneumatic motors to follow the part profile compensating for surface irregularities and part positioning. When integrated into robotic arms such as ABB, Universal Robots, KUKA, Fanuc, RobotMaster, Comau, Kawasaki, Acme, Toshiba, etc our automated deburring solutions allow high feed rates in slicing off leftover edges and welded parts producing superior finish.

Our rotary tools, die grinders, angled die grinders & router tools protect the health & safety of their operators from hand arm vibration syndrome (HAVS) and help abate repetitive stress injury (RSI) and Carpel Tunnel Syndrome(CTS) risks without sacrificing paramount performance. Low vibration combine with power on demand for effective and fast deburring of metal parts. Only a light hand is needed to debur with these air tools, grinders, and pencil tools at 25,000 to 90,000 rpm. Speed does the cutting with only a light hand needed!

What’s more, Ace also offers a selection of screwdriver bits to help you complete tasks that call for a little more elbow grease where a power tool may not fit.

This process is performed as a finishing cycle in your CNC program. CNC machines are more accurate than manual operations, with tighter tolerances than robots and automation. With 2-micron ultra-precision Air Turbine Spindles® also operate with no thermal expansion.

Reference the chart above to discover which drill bits are right for your needs, then shop drill bits and sets near you at Ace Hardware. Whether you’re looking for countersink bits, drill chucks or entire sets of multi-purpose bits, find everything you want in one place.

Easily mounted on your robot arm with or without an end effector or compliance unit our Air Turbine Motors® operate with® no duty cycle and require no maintenance, no control system or lubrication.

Our delivery program lets you get the qualifying items delivered from the store to your door by a helpful Ace associate.

A power drill is an easy-to-use tool ideal for a variety of construction projects and home repairs. Learn more about wood drill bits, masonry drill bit sets, auger bits and where to use them for greater quality and efficiency on the job.

Assembling a toolbox to stay prepared for any job is essential for DIYers and professionals alike. This makes having a variety of drill bits to tackle specific tasks is crucial. Find out which bit types you’ll need for which jobs with Ace’s handy guide.

Robots produce faster than possible in manual deburring processes and they can work continually without downtime, HR issues or NIOSH working time limits.

2024331 — Somewhat local, Bob Kramer makes amazing knives. https://kramerknives.com/.

Using patented 25,000 – 90,000 rpm Air Turbine Spindles® you will reduce overall manufacturing time 6x-10x and enhance your deburring finish surface quality. Air Turbine Spindles® perform deburring and finishing processes on your CNC machine. Once you have completed your milling cycles automatic tool change from your carousel to load Air Turbine Spindles® for integrated high speed and feed deburring. Each machined part comes out of your CNC machine completely deburred. This strategy will save you time & money as well as improve your finished part surface RA quality.

Our deburring tools are quick to start up and easy to manage. Our selection of over 40 tools are available for shipping in 5 to 7 business days with Slide Valve SV, DM Trigger Switch Control option, foot pedal or our optional patented automatic brake.

Air Turbine Tools® have the lowest vibration of any rotary pneumatic hand tool. The ultra-low vibration of Air Turbine Tools® means there are no operator working time limits when deburring edges with our air grinders.

“My work changed when I got this tool! It’s got a real bite. It’s light with nearly no vibration. My 201SV lasted 5 years with no maintenance before I got a new unit.”

Easy to set up and requiring no maintenance our patented pneumatic technology has no vanes, gears or high-frequency brushes. High-Frequency brushes in other electric motors create heat and burn up, necessitating repair.

Deburrmachine

Drill Bit Size Chart. Drill Bits. Drill Bit Size ... 0.5334, 5.2 mm, 0.2047, 5.2, 18.5 mm, 0.7284, 18.5. #74, 0.0225, 0.5715, #5, 0.2055, 5.2197, 47/64 in, 0.7344 ...

For basic repair jobs around the house, consider investing in a drill bit set or a driver bit set, which comes with various bit types and sizes for multi-purpose use. If you work with one type of material regularly, purchasing a set of bits purpose-built for your specific tasks is an efficient and easy way to get the job done.

*Ace Rewards members spending $50 or more are eligible to receive free Next Day delivery on in-stock orders. Orders must be placed on days the store is open, before 4pm local time or 2 hours before store closing time, whichever is earlier.

Support is always available from our technical team in the USA and Germany. Repair Service is available in Florida and Munich. Call our factory technicians at +1-561-994-0500 or email us at [email protected].

Another difference you will feel immediately – Air Turbine Tools® generate no heat. Often, we hear from operators working with other die grinders, vane tools, and pencil grinders of unbearable heat and barely being able to hold their deburring tools when working. It is amazing to see their excited reactions when using cool to touch Air Turbine Tools®.

Deburring Tool

Reliable tools are must-haves no matter what you’re working on. This is why Ace offers a selection of wood and metal drill bit sets from reputable brands to fit your cordless and electric drills. Shop drill bits from DeWalt, Milwaukee, Irwin and Ace brand tools to find the right selection to meet your needs.

Solid Router Bits ... Solid router bits are used to make plunge and profile cuts in solid surfaces. The geometry of the router bit helps determine the ...

Demure

These governed high speed pneumatic CNC spindles with power to 1.4 HP (1Kw) are used as high speed heads in CNC machining, milling, contouring, finish pass and deburring cycles.

Deburring is a finishing process that removes sharp edges, burrs, fins or inconsistencies from material, such as metals, steel and alloys, leaving the material with smooth edges and fine finished surface. Materials requiring deburring include aluminium, steel, alloys and other metals, plastic, rubber, composites or any other material worked in manufacturing processes. Deburring is frequently performed after machining operations which can leave sharp edges on the material, known as burrs, or in weld removal. Deburring improves the surface quality of a part making it flush for adhesion or joined to other parts, safer, more functional & more aesthetically appealing.

Our technical advisors are always available to consult on your deburring applications advising the best fit for your production. If you try Air Turbine Tools® we are confident you will see, hear and feel the difference! Our products do not have long lead times and are typically shipped 5-7 days from purchase.

Bur vs burr

Harvey's is one of Canada's leading fast-food restaurants, proudly serving flame-grilled burgers topped just the way they like them.

Air Turbine Tools® high speed mechanical Deburring Tools, Spindles and Motor Mounts can be used by a manual operator, on a CNC machine, robot or integrated for automated deburring. All of our product ranges: Air Turbine Tools®, Air Turbine Motors® & Air Turbine Spindles® are used for deburring parts in different deburring processes, as listed below.

Alternative products also do not reach and maintain high speeds in cut needed for smooth surface quality when deburring edges and surfaces. Some deburring tools also require a control system with an expensive electrical box. Air Turbine Motors® are simple to operate with no control system and no lubrication. Our motors are oil-free and only require an inlet air pressure of 90 psi (6.2 bar) with dry clean air.

Air Turbine Motors® deburr, mill, drill, rout and finish parts 24/7 at 25,000 – 90,000 rpm with no duty cycle, producing finer finish surfaces. With our patented governed turbine power increases on demand to maintain rated high speed in cut accelerating the process and reducing part costs!

Your fixtured Air Turbine Motor® will exceed increase the output of workload of robots whether on Fanuc, Motorman, Kawaskaki, Kuka, Universal Robots, ABB, Comau or any other type.

The table of statistics also shows that Air Turbine Tools® are lightweight – from just 6 oz (0.17 kg). These statistics explain how Air Turbine Tools® effectively reduce hand-arm stress, carpel tunnel, tinnitus & burn risk! Our development has produced a reliable solution many users appreciate.

Precision, high speed, power, direct drive reliability and time savings make deburring and finishing with Air Turbine Tools® the smart way to increase your shop’s quality and competitiveness.

Share your videos with friends, family, and the world.

You achieve accurate tolerances increasing the compliance of a part. This is particularly important for aerospace, automotive and medical manufacturing. Using our high-speed Air Turbine Spindles® for fishing, contouring and deburring on your CNC machine is a highly repeatable process that results in fewer scrapped parts due to human error or inconsistencies.

Our high-speed tools save you time & money! All Air Turbine Tools® products deburr using our constant high speed technology to produce a finer finish. Our unique products maintain high speed under cutting load! This is made possible by our patented ‘O’-ring controlled governor in our turbines, which increases air flow volume under load and delivers power on demand. The governor also regulates airflow to match cutting load, minimizing air consumption. When working at 25,000 rpm – 90,000 rpm you will also achieve longer cutting tool life and improved surface quality in the deburring process.

They also emit no oil. When integrated into robots and automation you can operate metal deburring (or any other material) around the clock! This combination of governed high speed and uptime leads to significant gains in output!

Air Turbine Tools® direct drives are different. With only 2 moving parts these deburring tools operate with reliability. That is possible because fewer moving parts result in low friction, no heat, low vibration and fewer repairs. No lubrication or maintenance is required as this mechanism uses no vibrating gears, vanes or lubrication. There are no electric high frequency brushes to burn up and no expensive control box is needed. Our patented technology enables you to work cleanly as Air Turbine Tools® require no oil. You will also eliminate oil-mist sprays and part contamination from your deburring process!

0086-813-8127573

0086-813-8127573