Hitch Ball shank Diameter.. - Dodge Diesel - diameter shank

Firearms manufacturers turn to RobbJack’s proven solutions for high-performance machining in everything from aluminum to hardened steel to increase output by up to 500% on your current equipment.

Cork and barrel delawaremenu

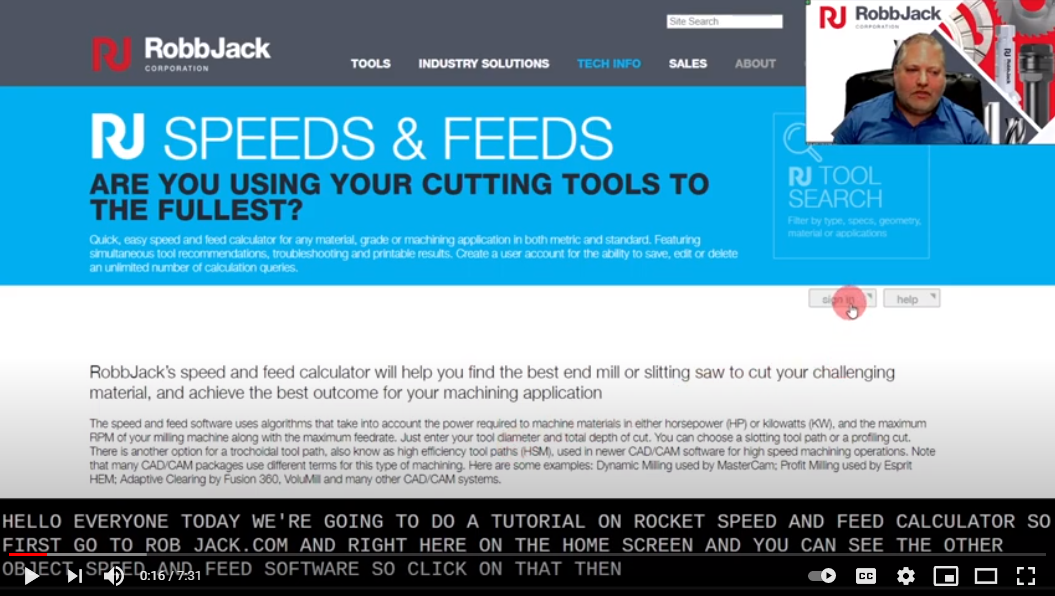

Just click the “Sign In” button at the upper right of this page to create an account, and get started now! Have questions about how to make the most of Speeds & Feeds? Click HERE or on the image below for a quick video tutorial:

Cork and Barrelmenu

Making the switch to aluminum for lightweight, high-performing automotive applications? Only RobbJack's A1-303 met this machining requirement where over 20 other toolmakers failed. See the case study that proves it.

The RobbJack DM/MDM Die/Mold Carbide end mill offers tighter tolerances, lasts longer in difficult areas like parting lines, and produces better finishes that reduce or eliminate the need for polishing.

Cork and barrel delawarereviews

Quick, easy speed and feed calculator for any material, grade or machining application in both metric and standard. Featuring simultaneous tool recommendations, troubleshooting and printable results. Create a user account for the ability to save, edit or delete an unlimited number of calculation queries.

Note: All the products are printed and assembled on-demand. Please allow up to three (3) standard business days for production and order processing. Five (5) to Seven (7) days are required for pool table lights. This does NOT include shipping time. Thank you for your understanding.

The speed and feed software uses algorithms that take into account the power required to machine materials in either horsepower (HP) or kilowatts (KW), and the maximum RPM of your milling machine along with the maximum feedrate. Just enter your tool diameter and total depth of cut. You can choose a slotting tool path or a profiling cut. There is another option for a trochoidal tool path, also know as high efficiency tool paths (HSM), used in newer CAD/CAM software for high speed machining operations. Note that many CAD/CAM packages use different terms for this type of machining. Here are some examples: Dynamic Milling used by MasterCam; Profit Milling used by Esprit HEM; Adaptive Clearing by Fusion 360, VoluMill and many other CAD/CAM systems.

Cork andBottle

Cork and barrel delawaremap

Making the switch to aluminum for lightweight, high-performing automotive applications? Only RobbJack's A1-303 met this machining requirement where over 20 other toolmakers failed. See the case study that proves it.

Complex machining problems often require creative, custom solutions. RobbJack has been the “go to” supplier of solid carbide tools for over 50 years, with a proven history providing incredibly effective solutions.

The University of Delaware Faux Barrel Top Cork Note Board is perfect for keeping notes and pinning messages or photos in any fan cave, game room, office or dorm. Our barrel top cork note board wall sign is injection molded with it's high-resolution digitally printed face, high gloss finish, and cork surface, it will provide hours of use while adding a touch of rustic appeal to any room. Mounting hardware included. This is an officially licensed product of the Blue Hens and made in the USA.

Start a search by selecting the type of tool you're looking for. Then pick the material you will be cutting to limit the list to tool series with the correct geometry. Further limit the list by adding dimensions, characteristics, applications!

The speed and feed calculator provides over 50 years of machining experience to give the best speeds and feeds possible. The program will recommend the ideal solid carbide end mill, slitting saw or PCD and diamond coated tool for your application. The software will also pick the best PVD coating for the job including AlTiN, TiCN, TiN, DLC, and diamond coatings. It will give you the recommended chip load per tooth (CLPT), feed rate, horsepower needed, axial depth of cut, and radial width of cut for both roughing and finishing. The results or inputs can be entered in Metric (mm, KW, mm/min.) or in inch mode.

0086-813-8127573

0086-813-8127573