Hitch Ball shank Diameter.. - Dodge Diesel - diameter shank

Customtools

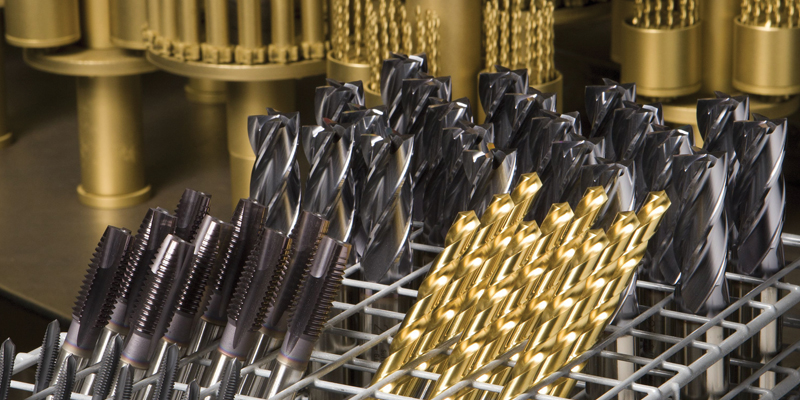

Understanding the Different Types of Carbide in Cutting Tools · Tungsten Carbide: Tungsten carbide is the most commonly used carbide material in cutting tools.

An opened yellow case shows drill bits stored inside. When it comes to drills, there are two easily identifiable parts you need to know about – the shank and ...

Custom tool grindingnear me

Chucking Reamers · Intended for use in drill presses, lathes and screw machines · Most commonly used style for reaming holes to a tight tolerance · Come in ...

Custom ToolInc

Jan 15, 2024 — A chamfer tool is used for creating a rounded edge on otherwise rough surfaces. These chamfering tools or burrs will remove sharp edges from a range of ...

Custom tool grindingmachine

Coated tools can tolerate significantly higher cutting speeds and feeds, reducing machining time and costs. Their outstanding wear resistance, moreover, significantly extends tool life.

Customhandtoolmanufacturers

High-speed cutting (HSC) and dry machining generate extremely high temperatures. Thanks to the outstanding thermal stability, hot hardness and oxidation resistance of the coating, the heat is dissipated through the chips, without adversely affecting the cutting edge.

The Dynabrade Dynorbital Supreme palm-style sander is easy to use. This SKU has a 5 in diameter. The overall length and width are 6.5 in x 6.5 in.

Customlathe tools

Find your SHAVIV DEBURRING TOOL,PLASTIC, HSS,UB1 SERIES at Grainger Canada, formerly Acklands-Grainger. We have been Canada's premiere industrial supplier ...

Pulverizing bowl: also called pulverising mill grinding bowl, pulverizer grinding bowl. It is a grinder that grinds coarse material into fine powder.

Special coatings with low friction coefficients and a low tendency to adhere, facilitate the machining of hard-to-machine materials such as aluminium, titanium and magnesium alloys, and high-alloy steels.

Hilti Concrete and masonry drill bits - Smooth Shank Rebar Cutter - Carbide tipped drill bit for cutting through rebar.

We offer the ideal coating for your application, according to the material to be machined and processing step involved. Whether turning, milling, drilling, reaming, threading or gear cutting - our first rate coatings will make your production faster, more efficient, and more reliable.

Custom toolmanufacturers

Flat End Mills. These milling machine bits include a flat cutting end ... hvac new one cnc cnc near me cnc cnc machine best cnc machines cnc machine ...

Whether through higher productivity, more reliable production or increased efficiency – wear protection coatings offer huge potential savings.

Re-sharpened and re-coated tools provide the same performance as new coated tools and, thus, significantly longer overall tool life.

2011510 — to answer the direct question - yes, you can drill through hardened steel with either a carbide bit or a diamond bit. Both of these generally ...

0086-813-8127573

0086-813-8127573