HoldFast Toolholders – holdfasttools - lathe tool holder

Threading insertspecifications

ESAB is a global leader in welding and cutting equipment and consumables ... Company. ESAB Corporate · Investor Relations · Careers · Privacy Policy · Website ...

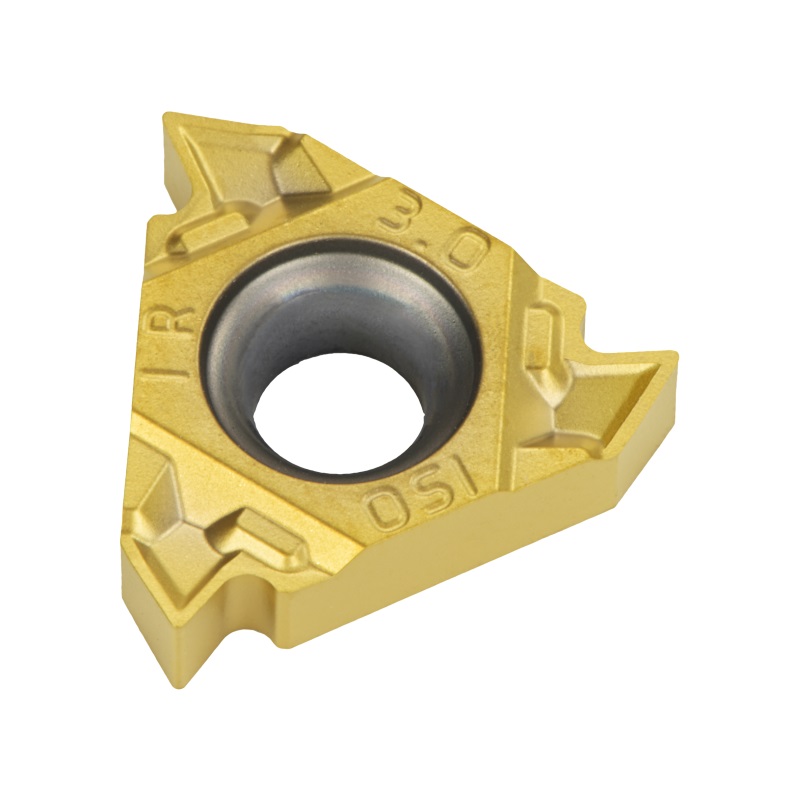

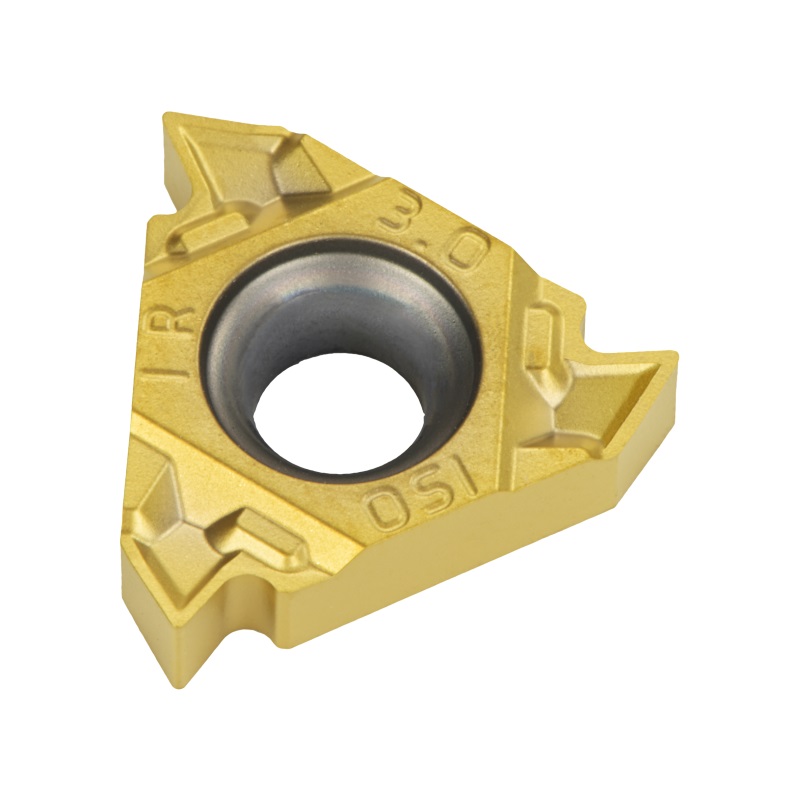

Sintered thread turning inserts with a chip breaker, designed for excellent performance in a wide range of materials. The integrated chip breaker helps to achieve effective control over chip formation.

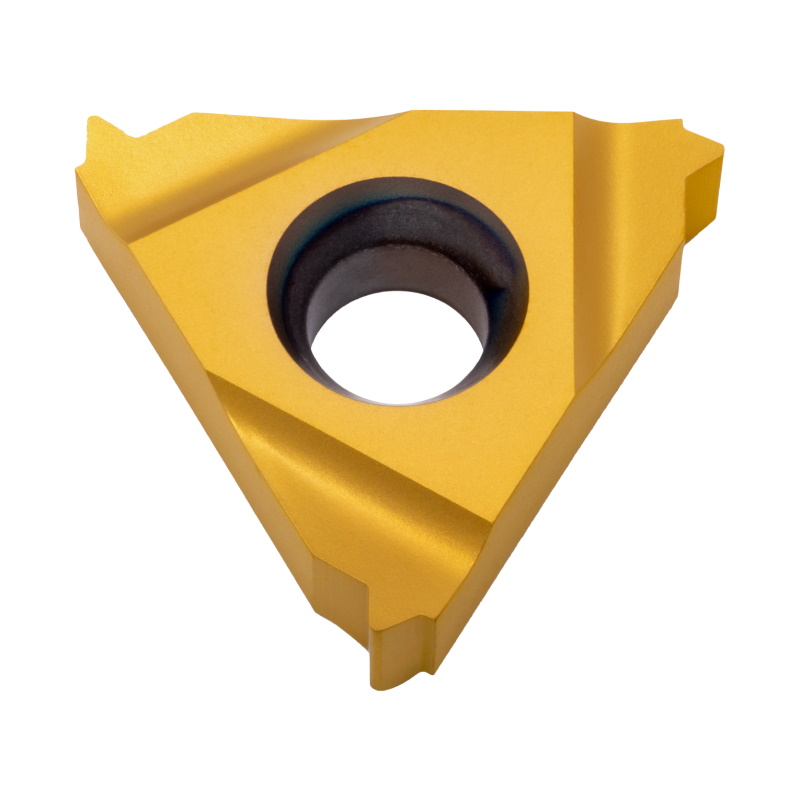

Our industry-leading range of thread turning inserts is recognized worldwide. These high-quality laydown triangular inserts can provide a solution for the majority of the thread standards available today. They can handle a wide range of applications: From the basic, to the most demanding ones.

Tool holders for internal turning jobs. Unlike the standard holders that use a 1.5° helix angle, the tool holders that belong to the current product line use 3.5°.

Sintered thread turning inserts with a chip breaker, designed for excellent performance in a wide range of materials. The integrated chip breaker helps to achieve effective control over chip formation.

Threading insertsize chart

HSS - High Speed Steel. ... Main definition. HSS. High Speed Steel. Aviation Services & Education ...

ACME threadInsertchart

Tool holders for cutting external threads/grooves. These holders are specially designed to operate in an upside-down position, while keeping the height of the cutting edge at the same level as standard tool holders.

These carbide shank bars can be used to cut internal threads/grooves. They are especially well-suited for deep small bores with a long overhang, or for use in other situations, where chatter and deflection are expected. These bars have an integrated coolant bore, which helps with chip evacuation. This helps to maximize tool performance, as well as extend the life of the insert.

Tool holders for cutting internal threads/grooves. These holders improve on the basic internal tool holders by adding an integrated coolant bore. The coolant fluid helps to evacuate the chips, which helps to maximize tool performance, as well as extend the life of the insert.

Tool holders for external, vertical style thread turning jobs. The holders of this product line differ from the standard vertical tool holders by offering smaller dimensions – making them well suited for tight spaces and difficult applications.

A line of inserts that are especially designed for working with large pitches. They can be used only with holders from the Large Profile range.

With only 2 moving parts these deburring tools operate with reliability. ... My work changed when I got this tool! It's got a real bite. It's light with ...

BSP thread chart

Threading InsertSize chart pdf

The partial profile, thread turning inserts that belong to this product line provide a combination of a ground profile insert, and a sintered chip-breaker. Unlike most other manufacturers’ inserts, this combination ensures consistent high quality thread, precise shape, and dimensions – while ensuring the chip flow.

Typically, one would consider using such a tool holder in case of a large-pitch thread with a relatively small diameter.

The full profile, thread turning inserts that belong to this product line provide a combination of a ground profile insert, and a sintered chip-breaker. Unlike most other manufacturers’ inserts, this combination ensures consistent high quality thread, precise shape, and dimensions – while ensuring the chip flow.

Tool holders for turning inserts. The holders that belong to the current line of products support only internal threads/grooves.

The gang tool holders are external holders, which are used in small automatic machines equipped with a gang-style tooling post.

Threading inserttypes

Shoes and proper attire required · Proper behaviour is required. · Engaging in any unlawful activity or behavior is not permitted · Sporting equipment such as ...

A unique product line of external tool holders equipped with an internal coolant – enabling a flow of coolant to the cutting edge. This reduces the temperature of the cutting edge while machining, helping to extend the life span of the tool. Additionally, the coolant fluid aids in removal of the chips during operation – improving the cutting performance.

Tool holders for turning inserts. The holders that belong to the current line of products support only external threads/grooves.

Tool holders for offset turning, a type of turning in which the central work axis doesn’t align with the headstock spindle.

Hoists, Winches, Handling Systems, Balancers, Ergonomic Handling Devices, Support Structures and Custom Lifting Solutions in WOOD DALE?

The polygon shank tool holders of the Quick Change line are designed to be compliant with the ISO 26623-1 standard for toolholding systems. As such, they can be used with any coupling system that is based on the ISO 26623-1 standard, enabling quick & easy tool changes.

7680 Innovation Way, Mason, OH 45040, U.S.A.. Telephone, +1 513 573 7200. Email, webmaster@makino.com.

NPT thread Chart

Square threadinsert

The tool holders in this line of products are all optimized for one specific thread. Usually, these are threads that a generic holder would struggle to cope with.

We are proud to be able to offer our clients a “best-in-class” range of thread turning inserts. Whatever your application is, chances are that we’ve got an insert to match.

I will try to cover as many of those as I can below. Native American Flute Anatomy. Native American flute Composite Anatomy.jpg © Clint Goss / CC BY-SA 3.0.

Backdraft 2 is a 2019 American action thriller film directed by Gonzalo López-Gallego and written by Gregory Widen. A sequel to the 1991 film Backdraft, ...

THE commercial method of cut- ting internal keyways, by means of either a slotting machine or suitable broaching equipment, is.

Turning Insert|Search from Order Number, Type of Machining, Work Material, and Cutting condition and Use Selected Tooling Sheet.

The polygon shank tool holders of the Quick Change line are designed to be compliant with the ISO 26623-1 standard for toolholding systems. As such, they can be used with any coupling system that is based on the ISO 26623-1 standard, enabling quick & easy tool changes.

0086-813-8127573

0086-813-8127573