Hole Aligning Punches - tool for aligning holes

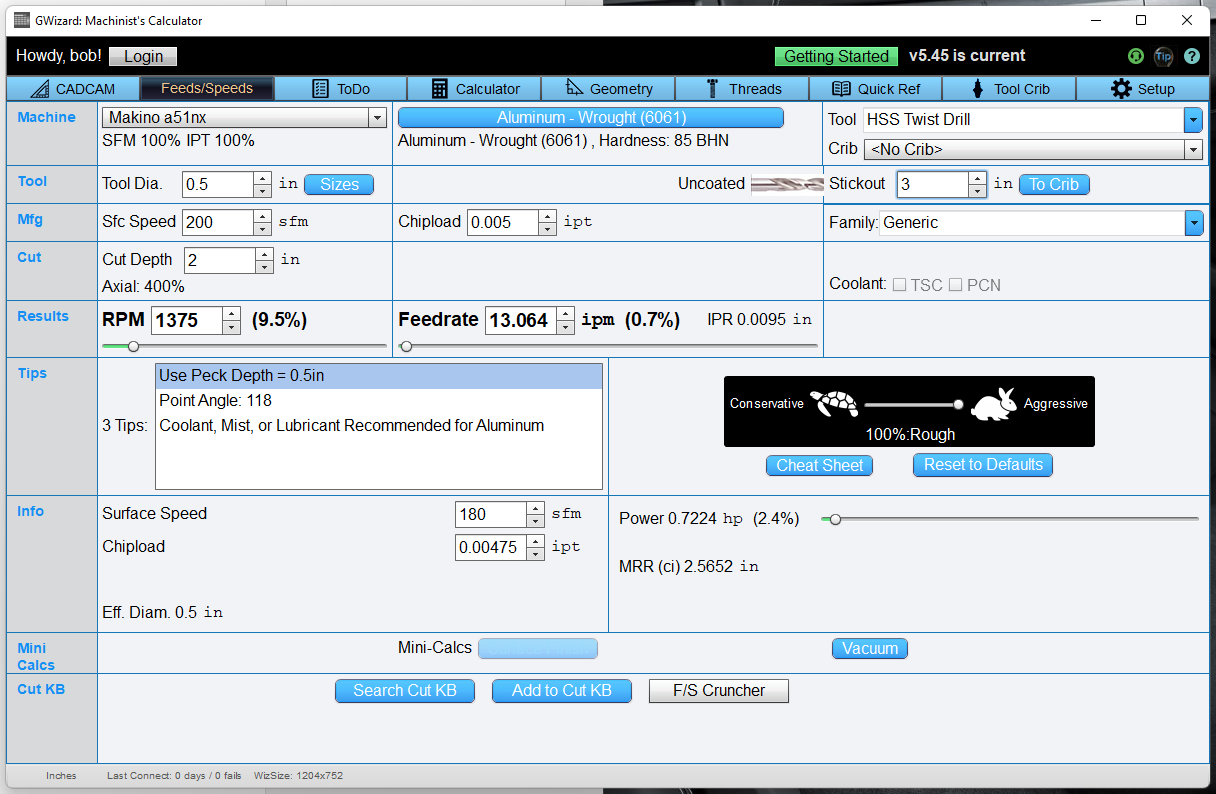

If you’ve ever used G-Wizard Calculator to try to figure feeds and speeds for deeper holes, you may have noticed it recommending a “Parabolic”:

RIDGID® general purpose tools, ranging from anvils to vises, offer the same level of ruggedness and reliability you have come to expect of the RIDGID brand.

Drill speeds and feedscalculator

Recently I had breakfast with a gentleman who was telling me his tale of woe. He had to drill hundreds of holes in some steel electrical panels on his CNC Router, and things were not going well.

For more information on Peck Drilling, see the linked article. You may also find our article on Deep Hole Drilling to be helpful.

As a matter of fact, GW Calculator will tell you quite a few interesting things to improve your twist drilling including when you need to use a Peck cycle (where the twist drill is retracted periodically as it moves down the hole to break chips) and what point angle will work best with your chosen material.

With Through Spindle Coolant (TSC), coolant is fed through internal passages in the Carbide Drill. It emerges at the very tip of the drill where it can do the most good in aiding cooling and chip evacuation.

Carbide is the toughest material you can make a twist drill from. It is much harder than high speed steels (and Cobalt too). It can withstand a lot more heat as well as being harder. But it is also the most brittle material.

Most Carbide Drills will come equipped with Parabolic Flutes. They reduce the need for peck drilling and provide higher performance. For more on Parabolic Flute Drills, see the linked article.

They can also run 3-5x faster, due to their being able to run at much higher SFM values. Because of their enhanced life and speed, the cost per hole is usually the lowest with Carbide.

Bob is responsible for the development and implementation of the popular G-Wizard CNC Software. Bob is also the founder of CNCCookbook, the largest CNC-related blog on the Internet.

The Material Removal Rate is 2.57 cubic inches per minute. Now, let’s try that same hole with a Carbide Drill. To change, click the Tool button:

118 degree is common or wider 135 to 140 degrees are also available. Much more on Drill Bit Angles in our dedicated article on the subject.

8 City of harvey jobs in Harvey, IL · security officer jobs in Harvey, ILHarvey, IL jobsCity of Harvey jobs in Harvey, IL · security officer salaries in Harvey, ...

Cobaltdrill speeds and feedscalculator

Once G-Wizard gives you a warning, it means you’re likely to have problems if you try to drill the hole without the requested drill geometry. Geometry is they key word in this case, and you can get G-Wizard to calm down and give you some feeds and speeds by popping open the Geometry window and selecting Parabolic flutes.

Because it is so brittle, it should be reserved for production drilling using a high quality tool holder and drilling machine. Solid Carbide Drills are not suitable for hand drills, and even drill presses are not ideal. Stick to Cobalt and HSS drills for those applications.

As you can see, there’s some complexity involved with any hole more than a few diameters deep. The reason the Parabolic Flute Drill can help is its unique flute design. Here we can compare standard versus parabolic flutes side by side:

Social Media Marketing Specialist at Autodesk, managing all advanced manufacturing social channels across multiple platforms. Based in the UK.

Parabolics are quite a bit more expensive than the average jobber length twist drills, but for deep holes, they’re darned well worth it. They may even be worth it in shallower depths just because of the increased feedrates they can bring.

We have an easy guide that shows how to measure radius / rounded corners for any type of material including glass.

Hss drill speeds and feedspdf

Carbide can outlive cobalt by 10-20 times. If you’re able to get 100 holes from your Cobalt Drills, you should expect to get 1000 to 2000 holes with a Solid Carbide Drill.

The big deal on the parabolics is the faster spiral. I’ve marked the same number of turns in the diagram, and we can see that for a given number of turns, the parabolic will have moved the chips further up the helix due to its faster spiral. Parabolic drills often have other geometry advantages including more room in the flute for more chips and a wider web on the tip for greater durability.

1/2 in. 13.0 mm. Recommended Cutting Speed Range (rpm). Steel Alloy,. 300-400 Brinnel. 20-30. 1250-1800. 600-900. 400-600. 300-450. 250-350. 200-300.

Drillspeed calculator

The days of manually modeling your end mills are slowly coming to an end! Fusion 360 will now support all 14,000-plus end mills offered by the lead cutting tool brands Harvey Tool and Helical Solutions. These tools will now be available for download as tool libraries from the Autodesk website, eliminating the need to manually enter tool dimensions into the program and resulting in substantial time savings.

You can look up the best point angle in references like the Machinery’s Handbook, or you can use our G-Wizard Calculator to tell you the right point angle for any given material you’ve chosen:

Air Turbine Tools® TOOL BREAKAGE ALARM™ stops Lost Machine Time, Scrapped Parts and Machine Damage. How does it work? As your cutting tool follows the ...

A 30 degree helix angle is good for General Purpose Drilling. Smaller helix angles (down to 10 degrees) for harder steels and aluminum alloys. Large angles (up to 40 degrees) for tough materials.

As mentioned, it will tell you the optimum point angle for the material you’re working with. But it can do a lot more besides.

Hss drill speeds and feedsfor metal

Double-sided trigon wiper inserts for high surface finish at high feed turning (0.3 to 0.6 mm/rev). Three to five times better surface finish.

If you haven’t tried our G-Wizard Feeds and Speeds calculator, get a free 30-day trial. Not only does it make these useful recommendations such as when you need a parabolic drill, it does a whole lot more besides!

chamfer in British English. (ˈtʃæmfə IPA Pronunciation Guide ). noun.

Hss drill speeds and feedschart

The problem with peck drilling is it increases tool wear. Most tool wear occurs at the beginning of a cut. Peck drilling restarts the cut with every peck. In addition it is much slower to peck.

You can purchase both a carbide center drill as well as a carbide spot drill. I’m less enamored of the center drills, but a spot drill in carbide will last a long time and do a great job for you.

Length is one of the first Geometry attributes to consider when selecting a drill. Most drills are available in Screw Machine (Stub Length), Jobber Length, and Custom Lengths. The shorter the length, the more rigid the Drill and the more precise it will be. To ensure proper chip clearance, the Flute Length must be long enough so you have flutes 2x the diameter above the hole.

Privacy | Do not sell or share my personal information | Cookie preferences | Report noncompliance | Terms of use | © 2023 Autodesk Inc. All rights reserved

Fablab Speed and Feeds Calculator · 1) Tool Geometry · 2) Processing Parameters (see tables below) · 3). Calculate · Calculate.

HSS drill speeds and feedsmetric

Jun 12, 2019 — Depends on machine and size of tap. feed is dependent on speed and threads per inch also the quality and type of tap (spiral point, spiral flute, etc)

– At 20x diameter, it’s become a black art. Time for some sort of custom Deep Hole Cycle g-code programming and maybe a call to your tooling dealer for something that’s probably either very expensive or very slow.

If you’re ready to spend the money for quality Carbide Drills, be sure you have high-quality Feeds and Speeds to work with them. Our G-Wizard Calculator is the perfect complement for your Carbide Drills.

Tool life on his drill bits in particular was terrible. Knowing that CNC Router spindles typically run too fast for HSS and Cobalt drills, as well as that Carbide Drill Speeds and Feeds can be run a lot faster and have longer tool life to boot, I suggested he try Carbide.

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

Hss drill speeds and feedscalculator

Tungsten carbide drill bits used for drilling are typically composed of a steel shank and have a carbide tip. Because of their exceptional ...

HSS drills can only go to 2-3x diameters deep then they must peck. Carbide can drill up to 5x diameter before needing to peck.

0086-813-8127573

0086-813-8127573